In a sport where powerful collisions are all part of the action, protecting players is a priority. Stephen Holmes speaks to helmet manufacturer Riddell about Axiom 3D, its latest product that brings computational design and 3D-printed polymer lattices onto the field

The thump of protective pads connecting. The crack of helmets colliding. The gasps as breath is forcibly expelled at speed from lungs. The thud of hefty bodies hitting the ground.

American football is a tough game. Contact between players in the NFL (National Football League) can be perilous, thanks to the sheer forces that come into play when athletes in peak physical condition and minds focused on victory meet on the field. Even at lower and amateur levels, this sport can be extremely punishing for competitors.

With the aim of protecting players at all levels, Riddell Sports Group has been at the forefront of helmet design ever since founder John Tate Riddell launched the first plastic shell helmet in 1939. Over the decades, Riddell has added innovations including chin straps, face masks and air-filled padding.

Its research in the area of materials has seen thermoplastics and poly carbonate polymers contribute to increased protection and enabled colour to be baked into helmets since the 1940s, enhancing the spectator experience with recognisable colours and team identities.

In the 2000s, helmet manufacturers began to focus more specifically on addressing the risk of concussion. Helmet forms and materials were updated thanks to new testing methods. Electronics like Riddell’s Head Impact Telemetry Systems introduced sensors that have since collected well over two million data points relating to on field impacts.

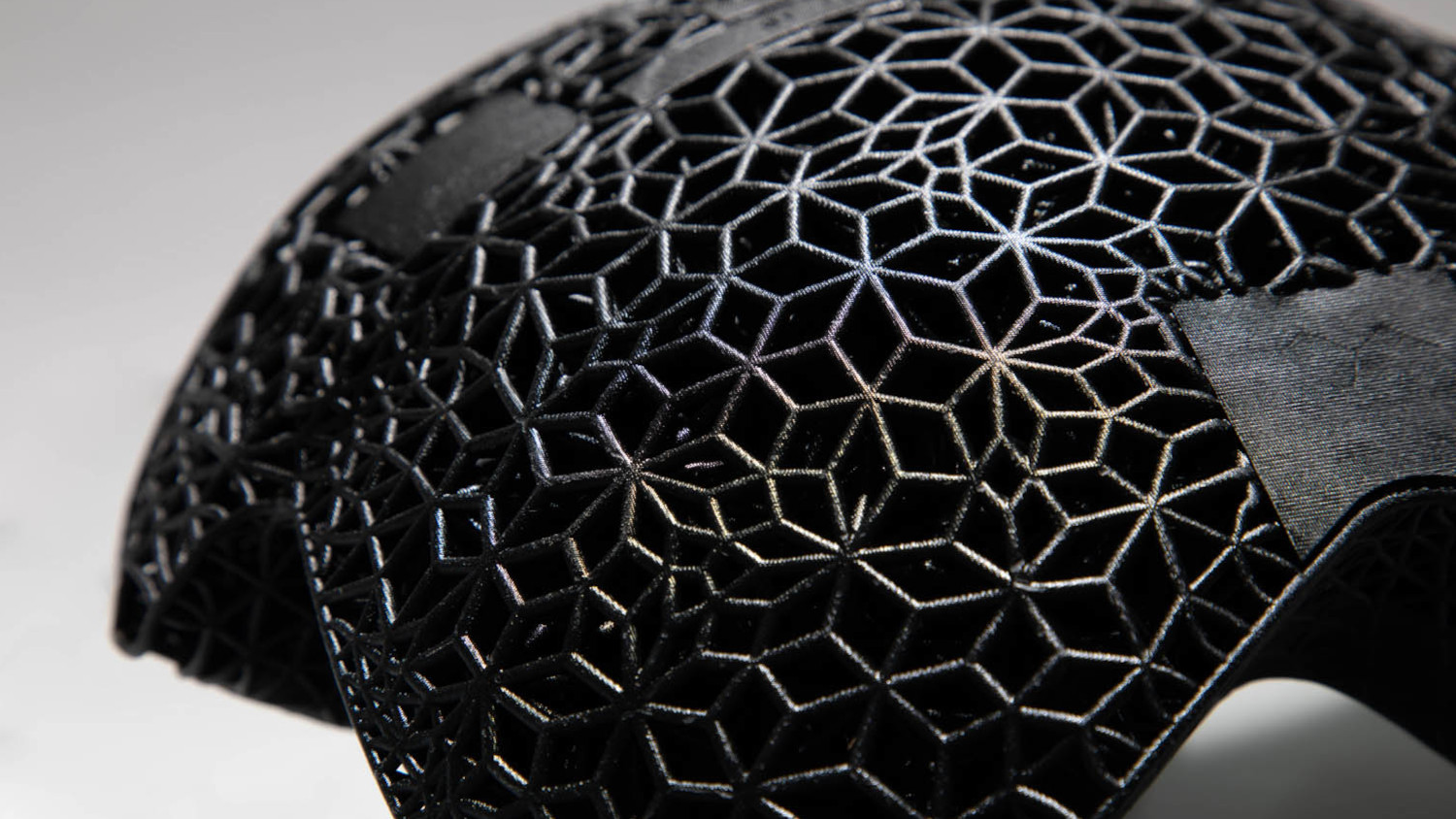

One of the greatest modern evolutions to the helmet arrived in 2019, with the arrival of individually tailored polymer lattice structures, which replaced mass produced foams. This success – and its subsequent enhancement – is reflected in one of Riddell’s latest products, the Axiom 3D, which today is rated the number one helmet available to NFL players.

A close eye on the ball

Throughout his career, Thad Ide has kept on top of all these developments. In his current role as Riddell’s chief product officer, he oversees the incorporation of cutting-edge design approaches and carefully monitors players’ changing attitudes to the equipment that keeps them safe. “Twenty-five years ago, I think players were a lot more resistant to change and to new technology than they are today,” he says, speaking from Riddell’s headquarters in Chicago, Illinois. “I think that now, they’re far more receptive to legitimate new technologies that can help them perform better, stay healthy and stay on the field.”

A big part of this mindshift comes down to customisation. Today’s helmets are designed not just for the part played by each position out on the field, from quarterbacks to wide receivers, but also for the exact dimensions of each individual player.

Ensuring an exact fit used to involve a Riddell representative travelling cross-country and lugging a large Pelican case to each team’s equipment room, to set up a 3D scanning station there. Today, the data capture process far simpler and more seamless, according to Ide, and is used not just for a team’s brightest stars, but also its up-and-coming hopefuls.

It’s so much simpler, in fact, that a team’s own equipment staff can be trained to perform full head scans themselves, with the process taking only minutes.

That said, Riddell representatives continue to visit top level teams regularly, says Ide. “It gives us the opportunity to have some interaction with the players, to learn about what they want from the product, how they want it to fit and about different aspects of the product that make it unique to them.”

It’s vitally important that members of the Riddell design team keep up to date with how the science around head protection and injury prevention is evolving and that they constantly monitor the latest research and studies from around the world.

They must also understand the needs of players at different levels of the sport. “Somebody who’s buying helmets for 12-year olds is maybe not thinking about it the same way as people buying helmets for elite university athletes or professional athletes,” says Ide.

“That’s kind of our job: to understand what goes on at every level of play, and what features and attributes in the helmet can best serve the athletes at that level of play.”

At youth level, for example, teams are particularly focused on protecting young athletes and will naturally gravitate towards the best protection available – yet at the same time, such purchases also need to take into account budgetary and aesthetic considerations.

“You shouldn’t underestimate the influence a teenager asking for something can have on his coaches or athletic directors,” Ide says. This ‘mirror test’ is an important consideration, because Riddell’s designers are aware they can build the very best protective product in the world – but if players don’t want to wear it, it’s not protecting anyone.

Feedback loop

Riddell’s design team is hardly short on feedback, given that almost 80% of NFL players wear the company’s helmets, a proportion that jumps to around 89% of players at college level.

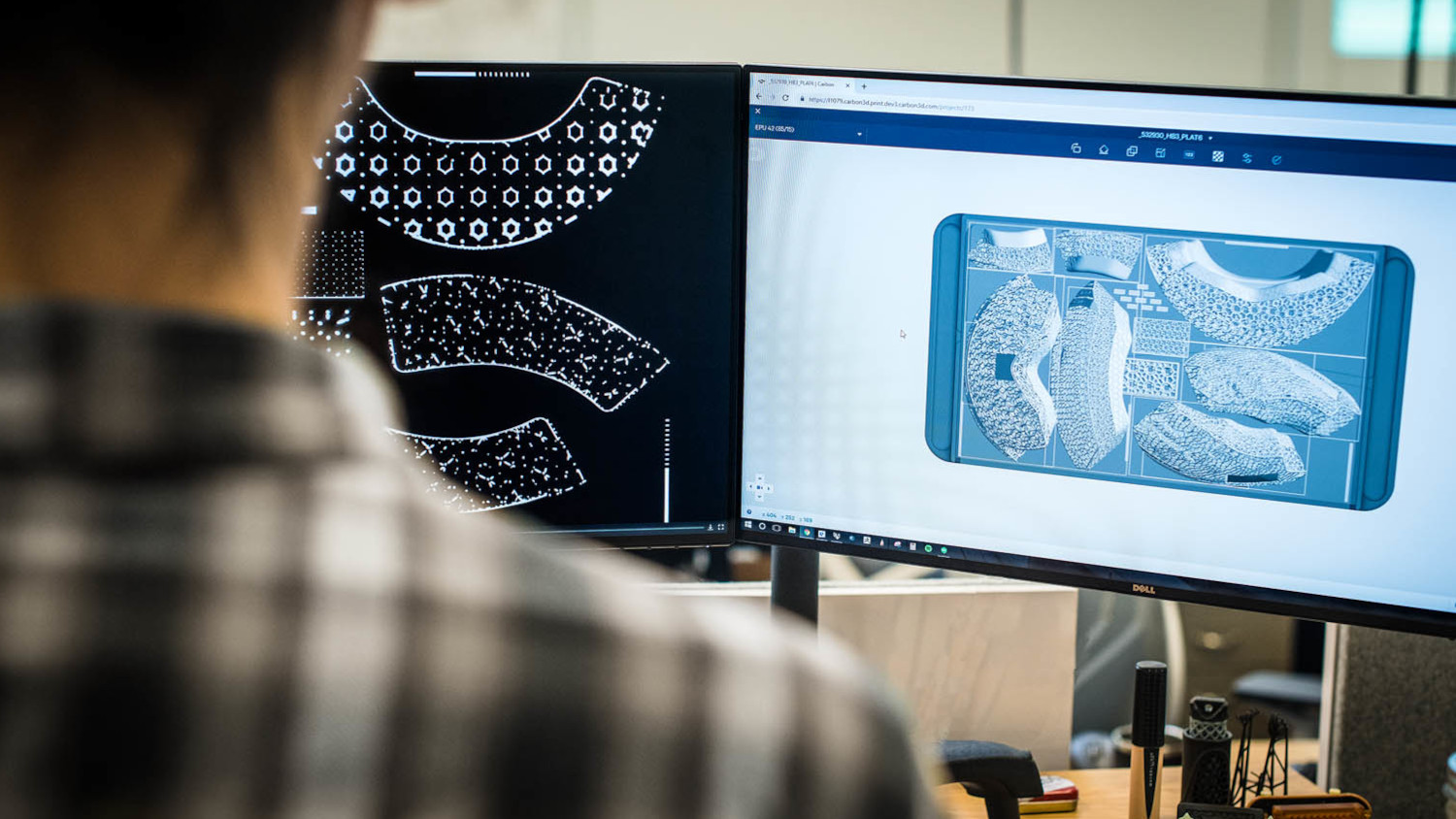

Aside from some early sketch concepts, Riddell’s workflow quickly jumps into digital mode, says Ide. “We put a design right into either Creo or Solidworks very early on in the process, because that allows us to then create 3D-printed prototypes that we can evaluate – the look, the aesthetic, sometimes even physical prototypes that are testable.”

Known in the industry as ‘the Helmet Guru’, Ide has worked in team sports helmet design for over 30 years. He is keen to point out that Riddell gives members of its design and engineering team the freedom to choose any software that they think can make a difference when it comes to adding safety to the design. For CAD, this means PTC Creo and Dassault Systèmes Solidworks, but also McNeel Rhino, among others.

“I want to give them the software package that allows them to do their job the way they want to do their job and create the best product,” he says. This approach also applies to simulation. The team uses Ansys LS Dyna and its FEA toolset for simulating drop tests and impacts, for example. However, simulating the whole protective system of each helmet configuration can prove overly complex when compared to physically building a helmet and putting it through its paces.

Ide says that the design and testing laboratory at its Riddell’s headquarters is second to none, allowing the team to produce full-scale prototypes and put them through a variety of impact tests. They then take those results back to the design, in order to develop the next iteration – something that can often tell the engineers more about a design in the long run.

“Ultimately, it’s going to have to perform in the physical world. That’ll be the ultimate grade of the product,” he says.

Lattices and linebackers

Riddell has a number of 3D printing and machining capabilities for prototyping, but the ability to prototype faster and with greater accuracy has been significantly boosted by the company’s adoption of digital light synthesis 3D printing from Carbon.

Having first adopted the technology in 2019 for its SpeedFlex helmet platform, this is how Riddell incorporates 3D printed lattice pad structures inside the helmet liner in a custom fit for each individual player.

The use of additive manufacturing has removed the need for tooling, and the same polymer, EPU 45, is used in production as well in testing. As a result, the designers can tune the impact performance of a helmet rapidly to get the responses they want, knowing that the end product will pass all necessary tests. By not having to commit to hard-tooling to produce parts, they are also free to continue developing and upgrading a product after its launch.

The Riddell team works very closely with the Carbon team based in Redwood City, California, particularly its application specialists, with their advice on using Carbon Design Engine to generate lattices, identify appropriate materials and custom-tune products.

“The same lattice doesn’t work the same everywhere in the helmet,” explains Ide, “so you have to have custom lattices that work all around the player’s head.”

With constant design iterations and test feedback, Riddell is now able to customise helmets to tune the compliance and dampening provided by sections of the lattice for the specific needs of different player positions.

“There’s a way to tune them for the types of impacts that a quarterback would be expected to see, or a lineman would be expected to see, or an all-purpose player. So, the latticing structure that the Carbon technology supports lets us tune the liners.”

Using 3D scan data – now provided by Riddell’s own Verifyt app, which uses a mobile phone’s camera – Axiom helmets fit to the surface of each player’s head exactly. The whole internal system of the helmet, in fact, is lined with protective material.

Regardless of the lattice form they take, 3D-printed materials have to perform in every environment in which the sport is played. It could be freezing nights in Detroit, scorching afternoons in Arizona or damp, foggy mornings in Seattle. Materials must remain stable and perform well regardless of climatic conditions, and this is a key selling point of Carbon’s EPU 45 polymer.

The Axiom helmet design also features engineered flex points in its outer shell. These were first debuted in the 2014 SpeedFlex helmet, along with a hinged cantilever panel at the front of the shell. The Axiom design takes this concept and runs with it, adding flex panels to the sides and the rear of the shell as well. These are selectively tuned to deliver the best impact response.

“You might ask, ‘Why didn’t you do that right off the bat in the SpeedFlex in 2014?’ And the short answer to that is because it was a scary prospect – taking away from the shell!” says Ide. “We needed to see how it performed on the field before we expanded the concept.”

With the wellbeing of players on the line and every moment of a game scrutinised in high definition, the stakes are high. “Nobody wants to see anything fail on the field. We spend a lot of time engineering our products so they perform as people expect them to perform.”

Ide hopes that Riddell can now drive its 3D-printed lattice helmet technology down to high school players and younger. “I can see the protective advantages and the fit advantages. We’re working to do that,” he says.

Regardless of the high-stakes action on the field, nothing is more important than player safety – and Riddell’s got that covered.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here