When Bugatti launched the Veyron – the first 1,000bhp road car, the first that could top 400kmph, and the first new car poster on teenage boys’ walls since the launch of the Lamborghini Countach – Jeremy Clarkson openly doubted that anyone would attempt such a crazily ambitious feat of engineering again.

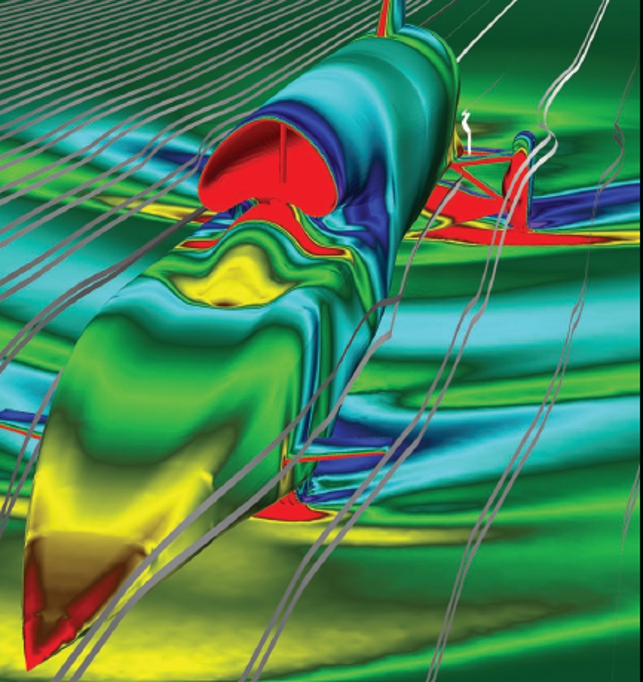

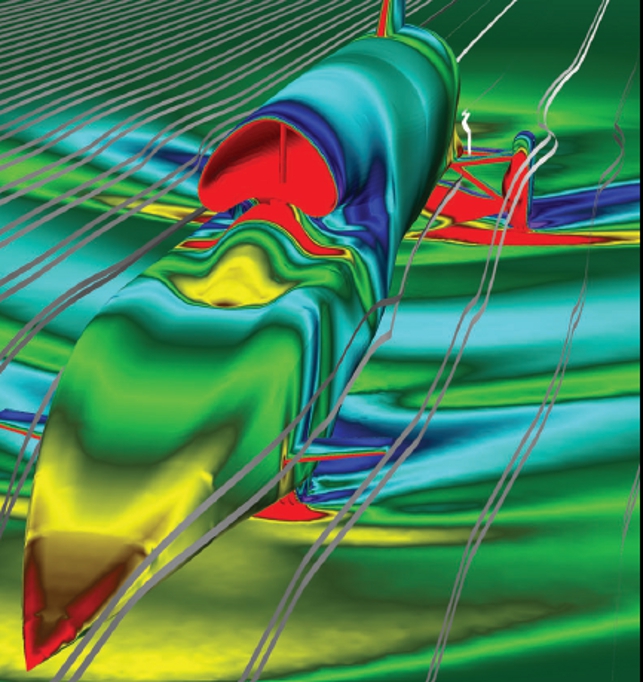

Sniffing out a world record: the Bloodhound Supersonic car using CFD simulation to help break the sound barrier

With more than a touch of wistfulness he bemoaned the purely commercial focus of today’s auto manufacturers and the lack of creative drive and innovation that goes with such hard-nosed territory.

As long as the people behind new cars are accountants, he reasoned, nothing genuinely new or exciting will ever get built again. He may live to eat those words.

A sense of adventure

Indeed it’s precisely because of the lack of landmark engineering projects in the modern age that the BLOODHOUND project came into being.

Lord Drayson, as part of his role as Minister for Science and Innovation, was charged with addressing the falling number of engineering students in the UK. Reasoning that interest in engineering has historically peaked with high-profile projects such as Concorde and the lunar landings, he was on the lookout for a new scheme that might have a similar effect. A meeting with land speed giant Richard Noble proved to be the spark for just such an engineering adventure.

Noble holds a distinguished place in the history of very fast cars. He was behind the wheel in 1983 when his jet-powered Thrust2 clocked up over 633mph and broke a record that had stood for 13 years. And it was through his leadership that Thrust SSC became the first car to break the sound barrier in 1997 when Andy Green recorded a speed of 763.035 mph, a record that stands to this day.

To beat this would be an amazing achievement in itself, of course, but that wouldn’t have been enough to get Noble back in the saddle (or Green back in the cockpit) so it seemed unlikely it would provide any sort of boost in engineering department applications either.

Raising the bar

Noble decided instead that he would aim not just to beat the land-speed record but to blow it out of the desert by reaching 1,000mph. This, he felt, was the kind of target that could inspire a new generation of young engineers. BLOODHOUND SSC was born.

Taking a car to such speeds is a phenomenal engineering challenge: 1,000 miles per hour is faster than the low-level air-speed record, after all. Hitting this kind of speed is more than just brute force and aerodynamics. A complex assembly of thousands of individual parts must be optimised so that everything is stable at every speed from subsonic, through the crucial transonic phase to supersonic. Any weak links in this particular chain could spell disaster.

The engineers and designers behind BLOODHOUND SSC are familiar with the challenges being faced, many of them having worked on Thrust SSC in the nineties.

A team of designers and engineers in Bristol took overall responsibility for decisions about the shape and construction of the car, while the crucial aerodynamic simulation function fell to the Engineering department at Swansea University.

Virtual testing

Professor Oubay Hassan, awarded the MBE for his work on Thrust SSC, headed up the team charged with the crucial task of simulating the performance of the car and its constituent parts. “For the Thrust project we used a combination of simulation and physical testing using a 1:25 scale model,” he explains. “The results from the testing (not to mention the successful run of the car) served to verify the figures we got from our simulation.

In order to work with the geometry coming out of the design team we’d have to write a new converter or input it all by hand

This time round the extreme nature of the project and the design window we were presented with made physical testing impracticable. Simulation has taken centre stage.”

Simulation, in this case, means FLITE, the computational fluid dynamics (CFD) system developed at Swansea for use in the aerospace industry. FLITE, versions of which are in use at leading European aerospace manufacturers, has been developed to simulate even the most extreme fluid flow scenarios and was one of the reasons Noble approached Professor Hassan for help on Thrust SSC.

For all its advanced capabilities, however, FLITE remains very much a specialist technical engineering tool, and does not feature the kind of CAD integration you would expect of a mainstream CAE solution.

“FLITE is a dedicated meshing and solving application, and it’s very good at what it does,” explains Professor Hassan. “But while we’re experts on engineering software we haven’t evolved a CAD interface. In order to work with the geometry coming out of the design team we’d have had to write a new converter or input it all by hand. And given the tight development schedule this would have been too much of a challenge.”

Enter CADfix

The solution came in the form of CADfix, the data translation and repair tool from ITI TranscenData. Using the CADfix API, the Swansea team developed an integration between the FLITE surface mesh generator and CADfix, that would act as a critical link between the design team’s NX CAD data files and the geometrical mapping required for the FLITE algorithms.

In addition to facilitating a direct interface to the complex NX design geometry, the CADfix integration meant that specialist CADfix geometry processing functions, such as the suppression of unwanted small features and the correction of poor surface parameterisations, could be applied to ensure that the optimum geometry was available for FLITE meshing and analysis.

“Geometry import was a serious headache,” adds Professor Hassan. “Before CADfix we were having to rebuild geometry inside our system. This was not only unsatisfactory but also hugely time-consuming. We could easily spend a week preparing geometry for analysis. With CADfix we were ready to go within hours.”

Towards the end of the design phase the software facilitating between 20 and 30 simulations of a critical element of the car’s rear suspension in a particularly tight timeframe.

Without CADfix smoothing the data transfer between design geometry and analysis mesh this degree of fine tuning would have been impossible and the optimum design not reached.

Professor Hassan estimates that without the data translation and repair tool the rebuilding of geometry would have added an additional twelve months to the BLOODHOUND SSC simulation. As he explains, this would have jeopardised the whole project: “The project leaders were adamant that the entire design cycle was completed within a year. Without CADfix this would have been impossible.”

The design phase for BLOODHOUND SSC was completed on time. Confidence is high that the deserts of South Africa will soon be resonating to the unaccustomed sounds of a Eurojet Typhoon engine propelling a man not just faster than ever before but faster than most people would ever have dreamed possible.

The simulation work means that, although this project does indeed represent an amazing engineering adventure, it is not quite a journey into the unknown.

www.bloodhoundssc.com / www.transcendata.com

Sniffing out a world record: the Bloodhound Supersonic Car