In 2014, 163 people lost their lives around the UK coastline, according to annual fatality figures recently released by the Royal National Lifeboat Institution (RNLI). Fortunately, the number of near-misses was higher, thanks to the work of the RNLI’s UK lifeboat crews and lifeguards, who saved 460 lives over the course of the year.

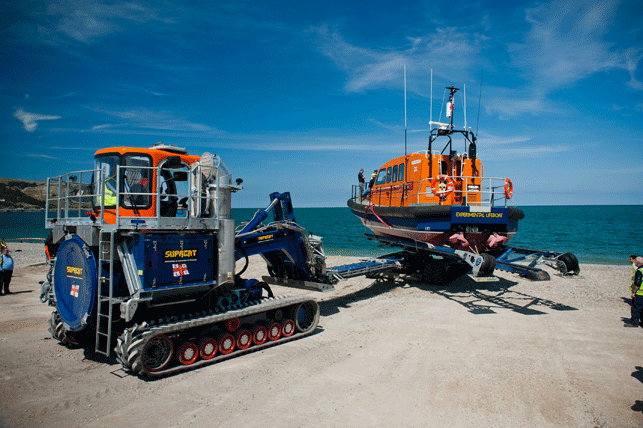

The Supacat L&RS enables crews to rotate beached lifeboats a full 360 degrees and relaunch them in minutes

This summer, RNLI lifeboat crews at four UK beaches were particularly well equipped when embarking on life-or-death rescue missions. At Dungeness, Exmouth, Hoylake and Ilfracombe, teams were working with new launch and recovery systems (L&RSs) designed by Devon-based design and engineering house, Supacat.

These robust, all-weather systems are capable of carrying the charity’s 18-tonne Shannon-class lifeboats to the water’s edge across gravel and shingle beaches and launching them even when wave conditions are at their heaviest. Each system’s rear cradle can be rotated 360 degrees, allowing a boat to be picked up from a bow-first beached position and then turned around ready for bow-first relaunch in five minutes flat.

“The first production L&RSs represent a great achievement by the RNLI and Supacat engineering teams, who have worked together for nearly a decade to design, develop and deliver this innovative project into service,” says Joe Wilcox, Supacat’s head of marine and renewables business.

Designed from scratch

Supacat designed the L&RS from scratch, with no preconceived idea of what the resulting vehicle system should look like when they began the project. The only design prerequisite outlined in the brief was that the company’s design team should use SolidWorks, in order to be able to collaborate with the RNLI’s own in-house CAD users. Supacat turned to reseller NT CADCAM for support in ensuring that its team had access the latest release of SolidWorks and that this was compatible with the RNLI’s installation.

The two biggest challenges that Supacat faced with this project were designing the vehicle so that it could maintain a low ground pressure and withstand extreme wave and weather conditions.

In response, its design team created a four-track drive hydraulic control system, which could support the integrated movement of both the tractor unit and the carriage elements of the articulated vehicle. They also designed a watertight cab and engine housing, capable of withstanding exposure to tides of up to 9 metres (the height of the highest ever recorded UK tide), as well as periods of total submersion.

“We needed to make sure the vehicle could be evacuated and left hatch-down, so that the engine bay and cabin do not flood, and could then be recovered when the tide goes out,” explains Supacat head of engineering, Nick Baker.

A further challenge was to understand the effects of corrosion in a coastal environment, he adds. “We did standalone salt-spray tests on components and most of the structure is hot-zinc sprayed to give components a 50-year lifespan.”

Complex assembly

SolidWorks met the design challenge with ease, Baker reports. “[It’s] an intuitive programme which, working with thousands and thousands of parts, proved more than capable of dealing with an assembly of this size.”

This was important, he adds, because the design team had already decided that any ancillary equipment needed for the lifeboat system would also need to be created in SolidWorks.

“We could have five or six engineers working on the L&RS, and bringing all those parts together for the assembly meant we could model and assemble most of the parts before manufacture. It gave us the advantage of being able to flag up any design issues or clashes, reduce scrappage and ultimately get the design right first time,” he says.

According to RNLI estimates, the combination of its Shannon-class lifeboats and the L&RS from Supacat means that each of these lifeboats will be able to rescue some 56,000 lives during their service lifetimes. A fifth L&RS is due for delivery at St Ives in November this year.

Says John Deas, RNLI principal engineer: “The L&RS solves the RNLI’s unique challenge of transporting, launching and recovering the 18-tonne Shannon class over some of Britain’s most demanding beaches, at lifeboat stations where there is no slipway or harbour and where there may be considerable tidal variation.”

“These are vital pieces of equipment, which ensure that our lifeboats can be launched and recovered as quickly and efficiently as possible, to save those in danger at sea.”

Onward journey

Supacat’s software voyage didn’t end with the design and build of its launch and recovery system for the Royal National Lifeboat Institution (RNLI).

In partnership with reseller NT CADCAM, the company went on to tackle its product data management requirements, having outgrown its existing Workgroup PDM system, and to explore closer collaboration with its Australian office, so that designers there could access, work on and store data in a company-wide shared vault.

The company had pushed Workgroup PDM to its limit, admits Supacat head of engineering Nick Baker. The product is intended for teams of between eight and 10 people, he points out, “but we were a team of 30 in the UK alone.”

A new approach was needed and the decision was made to implement Solidworks’ Enterprise Product Data Management (EPDM).

“The business case for EPDM was that it could increase our productivity by up to 20 percent,” says Baker. “Before, we used to manually create PDFs from the SolidWorks drawings, whereas now, it’s all part of the workflow. This is just one of the benefits that has made us slicker and more streamlined.”

“With EPDM, we have taken the pain and made the gains,” he adds. “The main reason was to link up with our office in Australia. We needed a replicated vault, as our engineers couldn’t work through the VPN connection into our UK vault and Workgroup limited us to one site only. With EPDM, we now have a system in place that can be expanded to other sites, both nationally and worldwide, if required. We have automated a lot of our processes and there is a lot more functionality that we are hoping to benefit from.”

RNLI teams saving lives at sea with launch equipment designed by Supacat

Default