Founded in 2008 in Seattle, Washington, USA, TLG Aerospace (TLG) uses state of the art technology to provide its customers – including OEMs, modifiers and new aircraft companies – with advanced engineering solutions. TLG’s core business is in airframe certification loads, dynamics, and flutter analyses.

TLG provides design, analysis and certification for new and modified aircraft

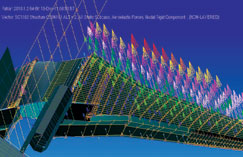

Working to rigorous FAA and foreign airworthiness specifications, TLG engineers participate in all levels of design, analysis, test, and certification of flight vehicles. The company uses MSC Software’s products, including MSC Nastran and Patran, as the core model development and analysis engines for aircraft certification.

MSC Nastran provides aeroelastic calculations that are advanced and flexible enough to handle modern transonic aerodynamic vehicles, but also fast and efficient enough to be usable for loads and flutter, which can require tens of thousands of individual solutions.

Aircraft Loads Analysis

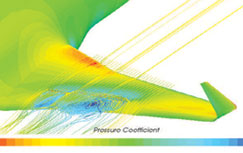

Aircraft loads are the forces and moments applied to the airplane structural components to establish the required strength level of the complete airplane. These loadings may be caused by air pressure, inertia forces or ground reactions during take offs and landings.

Determining design loads involves a full aircraft analysis of the air pressure and inertia forces during prescribed manoeuvres, either in the air or on the ground. Aircraft loads are needed at all design phases, from day one through certification and product lifecycle support. Early in preliminary design, structural designers need initial loads to size the preliminary structure.

As the design iterations progress, the detail and fidelity of the loads increases.

The final step for an aircraft is a full set of certification loads for submission to governmental agencies such as the Federal Aviation Administration (FAA) and European Aviation Safety Agency (EASA).

The loads analysis needs to cover all possible combinations of speed, altitude, flap angle, airplane gross weight, airplane center of gravity, passenger and payload distribution, fuel quantities, engine thrust and airbrake positions for each of the required manoeuvre and load cases for each part of the airplane.

Static loads are calculated for conditions in which the aircraft is assumed to be at steady state and ranges from high speed dives to low speed stalls.

The dynamic loads are how the airplane responds to gusts and bumps, including landing. The input data to the loads analyses accurate airplane geometry, aerodynamic data, weight (inertia) data, design speeds, stiffness data, miscellaneous systems data, operational data and regulations and requirements. This makes loads a multidisciplinary process.

Early in a design program, these parameters can be estimated from various methods. As the design becomes more detailed and defined, the inputs will be more refined, and for the final certification level, verified by test.

TLG has developed an extensive set of tools to facilitate quickly setting up and running a large number of static and dynamic loads cases and then rapidly post-processing to obtain the most critical load cases, and then providing “loads envelopes” to the stress and structural engineers.

TLG utilises MSC Nastran as the core aeroelastic solver for both static and dynamic loads for these surveys. MSC Nastran SOL144 and SOL145 are very suitable for these calculations, which require both structural and aerodynamic capabilities. Specific features, recent enhancements and upgrades have increased its utility.

Aerodynamic data can be input directly on aerodynamic or structural meshes

Aerodynamic pressures may be calculated from the built-in doublet lattice solver or alternatively input directly as pressures or forces on structural grid points.

All of these aerodynamic variables may be linked to control variables and used in the airplane force balance for flight maneuver conditions.

This capability allows TLG to input real-world data directly into the model, even if the results are difficult to calculate with the industry standard doublet lattice model.

Examples include engine thrust, aerodynamic effects of deployed spoilers, and high trailing edge flap deflections.

User-defined input variables

MSC Nastran allows arbitrary combinations of user-defined inputs to be used as part of the balanced airplane calculations.

These inputs can control arbitrary pressure inputs as mentioned above, or existing MSC Nastran trim variables, or combinations of existing variables.

This functionality allows TLG to perform such tasks as balancing the airplane in any way needed for particular calculations, defining control surface relationships such as control wheel to aileron gearing, or linking any set of balance variables together.

Separate rigid and flexible mesh

A single aeroelastic trim calculation can be performed using one aerodynamic mesh for the rigid aerodynamics and second aerodynamic mesh for the flexible increment. TLG uses this capability to maintain total control over the aerodynamic data.

Monitor points

Loads calculations require complete user control over how the aerodynamic and inertial loads are tracked and accounted for in the downstream output.

Structural FEM and aerodynamic mesh elements do not inherently provide this level of control. The aerodynamic and structural monitor point capability in MSC Nastran allows TLG to define engineering-level loads summations to sort for critical conditions and to provide loads to stress engineers.

Flutter

Flutter is an aeroservoelastic phenomenon in which unsteady aerodynamic forces combine with structural vibrations to produce a self-feeding oscillation which, if unstable, usually leads to airplane damage!

Flutter analysis is done to ensure that the aircraft is safe and free from flutter at all points in the flight envelope. The interaction between structural vibrations and unsteady aerodynamics are modelled to show whether an airplane will respond in a stable or unstable fashion to atmospheric or other disturbances.

The FAA, EASA and other agencies require that the aircraft is shown to be free from flutter for all nominal flight conditions and for critical combinations of failed systems and structures.

All possible combinations of fuel, payload and operating conditions must be considered.

Flight flutter tests must be performed for some of the conditions to demonstrate the accuracy of the analysis and to prove the airplane is safe to operate. TLG uses MSC Nastran SOL145 for flutter analysis.

The results show which airplane types of vibration result in flutter and at what airspeeds the flutter occurs. Variations in the analysis model can show which design changes can be used to improve flutter behaviour.

Aircraft Design Cycle

TLG’s areas of expertise form core parts of the aircraft optimisation design cycle. Aircraft design is an iterative process; early in the design phase, a loop around the design cycle may take only a few days or weeks. As the design matures and the detail increases, each additional loop may take months.

When all the requirements are met, it’s time to build an airplane.

The design starts with Design Requirements and Objectives (DRO). Along with size, performance and weights, the DRO includes cost objectives and certification requirements. Engineers work from the DRO to create the initial airplane configuration.

Once an initial configuration is defined, the first design cycle begins. Estimates and approximations for input data are required – the aerodynamic analysis needs structure and weights design data, structural design requires loads data, and the loads analysis uses aerodynamic, structural, and weight data.

After the initial design process, the results are compared against the objectives, assumptions and data are revisited, and an updated design is created. This process continues throughout the design, development, and certification process. Initial design phases involve numerous, relatively short design cycles as the configuration evolves to meet requirements.

Later design phases are longer and involve higher fidelity data and more complicated analyses. The cycle continues through the project certification, as the certification loads depend on ground and flight test validation of the final dataset.

tlgaerospace.com

mscsoftware.com

MSC software takes aerospace engineering design to a new plane of excellence

Default