The life of a product design consultancy is certainly one of variety.

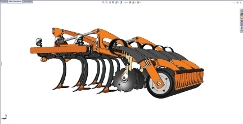

The new disc cultivator underwent field testing before it was officially launched in January 2010

A number of projects are taking place simultaneously all at different stages. And, whereas traditionally product designers were just involved in the physical design of products, nowadays the service they offer can involve research, branding, engineering design, project management, as well as liaising with suppliers and manufacturers on behalf of the client. Additionally, projects can encompass all or just some of the stages involved in design and development.

Haughton Design, based in Stafford, UK, is no different. It gets involved in a wide range of projects from a window lock or golf putter through to fittings for an induction welding system and a subsea vessel signal monitor.

Although offering a full design and development service from concept design through to manufacturing support, clients can dip in and out of the Haughton Design service offering depending on the project – whether it be a product refresh, a design rescue, help on the mechanical design side or a full product development.

Managing director, David Mills, whose background lies in mechanical design having worked in the automotive, aerospace and advanced manufacturing industries, set up Haughton Design back in 1995.

Although initially offering mechanical engineering support he has since grown the company to provide far more. “By having an engineering background, as we’ve grown we’ve been able to offer more styling and integrate it to provide a complete design development service from concept to manufacture,” he explains.

Like many consultancies, Haughton Design has concentrated on getting the job done rather than shouting about what it can offer clients. But with a newly revamped website, recent ISO 9001 accreditation and new marketing strategy, the consultancy is starting to become more vocal.

One way of doing this has been to send emails to prospective companies about its product development service. One such email arrived in Adrian Hartley’s inbox at just the right time.

Farm out

Adrian Hartley is the chief engineer at Simba, a manufacturer of agricultural machinery based in Sleaford, Lincolnshire, UK.

At the time, Simba’s agreement with a German manufacturer to sell its range of products only applied in the UK. To give export potential, Simba decided to create its own cultivator.

However, as the new TL300 machine was to compete with up to a dozen similar machines on the market, it not only had to perform better but look better too.

“We evaluated the German manufacturer’s machine as well as those from other manufacturers and came up with our own brief, which I then did initial machine layouts for,” recalls Hartley.

“Our chairman at the time said that we should look at having a more stylish appearance to our products. Fortunately I had just received an email shot from Haughton Design so I got in touch.” During the initial meeting with Hartley, Haughton Design came to understand exactly what was required for this product refresh project.

Essentially, the brief was to create a fresh aesthetic for the line of tine cultivators in order to make them stand out from the competition and help strengthen the brand. “Our intention was to look at the historic branding, modernise it and strengthen that corporate identity,” says Lee Smith, Haughton Design’s head of design.

“Adrian had explained that they would like a streamlined, flowing look to the design which gave the impression of speed and efficiency. The idea being that potential buyers would get the impression that it was a fast working machine. The styling should also give it a greater perceived value – it needed to look more expensive than the previous product,” he adds.

Helping hand

Having previously worked closely with the West Midlands regional branch of the Manufacturing Advisory Service (MAS), a government funded agency providing support to manufacturers, Haughton Design suggested to Hartley that he enquire about funding.

So, Simba approached MAS East Midlands and was given a grant to cover the costs of half the project. “I didn’t even realise there were initiatives like this available to manufacturers,” admits Hartley.

With just eight weeks to deliver the new design, Smith kicked off the design process by producing a variety of concept sketches. With Hartley having provided him with the Autodesk Inventor files of the machine layout, he had a framework to work within. “Typically we produce a lot of broad brush outline sketches by hand,” explains Smith.

“We show those to the client and they either pick their favourite concept for further development in 3D or it can be a pick ‘n mix of the different features they like.” The next stage is refining the chosen concept and it’s at this point that they get into SolidWorks.

He then went about manipulating and adapting the form of Hartley’s existing mechanical design. “We couldn’t deviate too far from what Adrian already had – the challenge was to still embrace the functionality that he had come up with but introduce these forms that give it a more streamlined look. For instance, the bow shape we created gives it a sense of tension,” explains Smith.

Track record

As Haughton Design has vast experience in design for manufacture it ensured that the styling features would be feasible to create and cost effective to manufacture.

“Our experience in similar industries and our background in mechanical engineering has helped us on this project because we could have a sensible conversation with Adrian about the different ways of manufacturing this rather than just dreaming up fancy shapes,” says Smith.

“We were able to change some areas to make it more cost effective and were talking constantly with Adrian throughout the project, the idea that if we did that from the start, we knew that our nice sketch would carry all the way through to final manufacture,” he adds.

Haughton Design produced a number of CAD renderings, which Hartley then presented to Simba’s board of directors and sales team. This was a crucial stage as Hartley had encountered some negativity from colleagues at the start of the project.

In order to help them visualise it even more clearly, one of Smith’s renderings featured a photograph of an existing cultivator with the new cultivator rendered over the top of it to show what it might look like out in the field churning the soil. “They were very impressed,” smiles Hartley.

However, the project was very much a team effort with Hartley providing input all the way through. This helps knock a lot of the risk out and ensures a successful outcome as the client knows what to expect.

“When companies place orders for design there is that anxiety of not knowing you are going to get for what you paid for,” comments Smith.

“What we have done is introduce client checkpoints spread evenly throughout the design process to try to reduce the risk of the client not liking what is produced at the end. But to be honest that never actually happens because the client is always involved all the way through. The client is part of the design team.”

Lost in translation

Once Hartley had approved the design, Smith sent him the SolidWorks STEP files. Although you would think this would be a fairly straightforward transfer of data with Hartley adapting the new styling lines back into Inventor, it was not.

In fact, Hartley had to redraw everything because of the different file types. “It’s like most of the CAD systems – there is no true data transfer from what I’ve found,” he comments. “The problem is that you lose originality of data.”

As a result, he had to create a new sketch on a flat plane and then copy and paste Haughton Design’s 3D model into it.

Mills wishes there was an easier way to transfer data between CAD systems as he claims it would save Haughton Design a fortune. “It’s a big problem to us because as a consultancy we don’t know who is going to appear at the door with an enquiry and we have so many different CAD packages that we have to consider it’s almost impossible,” he says.

Smith adds, “Also designers get used to one package and if they have to hop around on different packages they aren’t going to be as efficient.”

Simba then produced two prototypes of the TL300 stubble cultivator, which were used for field testing. Following these trials throughout 2009, a few slight changes were made to enhance performance and bring costs down.

In January 2010 the product was successfully launched with customers commenting on its new appearance. “For us it was interesting how you could add form to the easily formable parts that were either square or rectangular before.

It just shows that visual appearance of products is becoming ever more critical,” says Hartley. “Since this project we’ve taken a lot of the styling cues, especially the curves, from this machine and carried them over to products that we have done since.

So there will be a family resemblance as we refresh more of our range.”

Time is of the essence

In December 2010 Simba once again called on Haughton Design for an extremely quick turn around project.

Earlier in the year, Simba had been bought by Great Plains, a US agricultural implement manufacturing company based in Kansas, resulting in Simba being rebranded as Simba Great Plains.

In September 2010, the design teams in Kansas, US, and Lincolnshire, UK, embarked on their first joint project since the acquisition – a cultivating seed drill.

The aim was to launch a prototype of this new machine at Cereals 2011, a major agricultural event taking place in the UK in June 2011.

By December 2010 the teams had created the mechanical design for the 6m wide machine.

However, they decided that they needed some styling input for the 4,100 litre hopper, which holds the seeds at the top of the machine.

This is the largest visual element of the machine measuring 1.5m wide x 3m long x 2.5m tall. “People didn’t expect us to have anything on our Cereals 2011 show stand so soon after the acquisition, that was the driver through all of last year and the main push was that Haughton Design had such a short timescale to actually get their styling work delivered,” says Hartley.

With just three weeks in January 2011 to deliver final renderings of the design it meant all hands on deck.

“Everybody had an input in the design – all the guys at Haughton as well as the guys at Simba in the UK and Great Plains in the US,” says Hartley. “But we had the confidence in Haughton Design subsequent to the initial project we did in 2008.”

All Hartley provided Haughton Design with were the dimensions of the rectangular hopper and gave them free reign on the design.

“Again we were applying this streamlined, flowing design – giving the idea of it being fast and efficient,” says Smith. “What we have ended up with is a design that looks similar to a modern train.”

Once the renderings were approved, Haughton Design provided Simba with the CAD files, which were transferred into Pro/Engineer, the system Simba has moved to since the acquisition. From that data they created the 3D models and the tools were cut directly from those models.

Hartley then flew over to the US in March 2011 to see the machine 75 per cent assembled and the first time he saw the styling panels was when the assembled machine arrived at Simba’s Sleaford factory in Lincolnshire in May 2011.

Show stopper

In the nick of time the prototype of the Centurion seed drill was launched at Cereals 2011 and was very well received, according to Hartley.

Many visitors to the stand commented on its visual appearance. “If we hadn’t done it and gone down the road of having a rectangular box I don’t think it would have been as well received.

Our machine both performs better and looks better than the competitors,” comments Hartley.

With a recently expanded manufacturing facility at its Sleaford site, Simba Great Plains will initially produce the 4m and 6m wide versions there with 3m and 8m versions following in 2012.

Although Hartley admits that an investment in design has been worthwhile for Simba not all companies are like Simba and willing to employ the services of a design consultancy. “Sometimes companies look at involving a third party like us as a cost rather than an investment.

It’s difficult to measure how much effect that has had on the company from a cash point of view,” says Mills. “Like with Simba, an investment in design generates demand and provides a real advantage over the competition.

We are keen to explain that to people and make them more open minded about what design can do.”

A good grilling

Simba was eligible for part funding from the Manufacturing Advisory Service (MAS), a government funded organisation, for the development of its TL300 disc cultivator.

However, as Simba’s chief engineer Adrian Hartley says, he wasn’t aware that there was funding available to manufacturers such as themselves for new product development.

MAS West Midlands (MAS-WM) is especially active in this area and for a number of years has implemented a New Product Development (NPD) Programme helping over 50 companies in the region bring their ideas to market.

A product idea will initially be assessed by the NPD Panel and if they think it is viable and can be commercialised it will go through the programme.

This structured gateway process consists of six development stages and gates all defined to mitigate the high risks inherent in NPD.

As well as the 50 per cent match funding, MAS-WM will also offer support by introducing the company to various suppliers and experts who could help bring the product to market.

“We’ll work with a firm, whether that be a large organisation or a lone inventor, on the initial concept and identify what assistance they need and then bring in the best people to deliver that,” says Roy Pulley, innovation team leader at MAS-WM.

One great success story has been the Grillstream, an addition to any regular barbecue that prevents flare ups and smoke.

The technology works through double ‘u’ shaped grills that uses the science behind surface tension to capture and channel oil and fats away from the heat source and into a fat catcher on the barbecue.

The two founders originally took their idea to the Dragon’s Den. Although rejected it went through MASWM’s NPD programme and is now highly successful.

As well as funding they were introduced to key suppliers such Roson Engineering (tooling), Regent Engineering (presswork) and Ellison Coating Systems. “Grillstream is a great example of how the NPD Programme works.

The duo had a simple yet outstanding idea to solve an everyday problem and we helped them to access CAD facilities for prototyping and more recently supported them on securing patents,” says Pulley.

Launched in 2009 Grillstream has since gone on to secure license agreements and also diversified its product range, now offering a ‘360 Replacement Grill’ for charcoal kettle BBQs.

The MAS-WM NPD Programme is a great model offering comprehensive product development support.

As Pulley says, it’s more than money, it’s about coaching and mentoring. However, in 2012 things are going to change as MAS will no longer have regional branches but the hope is that, considering its track record, it will be rolled out nationally.

Haughton Design helps Simba dig for commercial victory

Default