Computational Fluid Dynamics (CFD) is rapidly gaining mind-share in many industries, from the earlier adopters in the aerospace and automotive/auto-sport world, through to more mainstream applications such as pumping or electronics cooling.

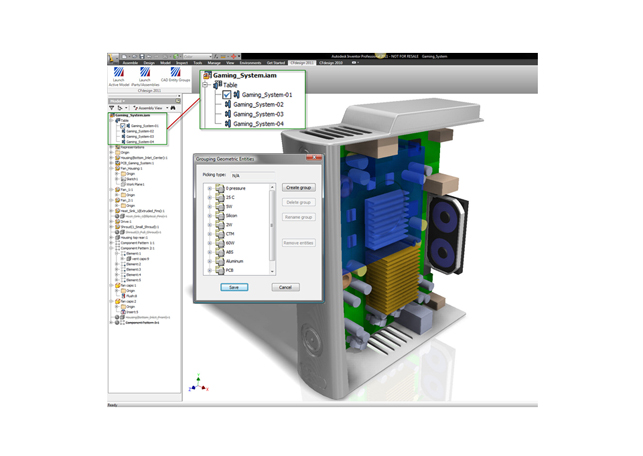

CFdesign allows users to leverage CAD intelligence such as part names and material. CAD groups allow for additional intelligence to add such as inlets, outlets and heat loads

By allowing users to simulate how a product interacts with fluid either internally (in the case of cooling or pumping) or externally (in terms of aero-dynamics), it can now be accomplished by pretty much anyone with a sound knowledge of the performance of a product and its operating conditions.

One of the vendors at the vanguard of this new designer-focussed simulation world is Blue Ridge Numerics. Its CFdesign application has been CAD-integrated from day one and has an impressive development track record. While it’s not built directly into the CAD system per se, the team has managed to ensure that the workflow with CAD data (Pro/Engineer, SolidWorks, Inventor and many others) is as seamless and as beneficial to the user as possible.

Blue Ridge Numerics has just launched a new release so let’s run through some of the generally applicable updates to CFdesign 2011.

The first is the user interface (UI), which has been overhauled over the last few releases. From being a special purpose tool as part of the CFD simulation process, CFdesign has now become a familiar 3D design tool with a UI that can be matched to popular CAD system’s mouse buttons and keyboard shortcuts such as view rotation, pan and zoom.

CFdesign 2011 further extends this by presenting comments relevant to the current task at the cursor point, ultimately meaning less reliance on toolbars and icons. As CFdesign can now be driven purely from the model/mesh/results display window, the screen seems bigger and clearer as it’s less encumbered with toolbars.

Elsewhere the system has been updated with a greatly expanded materials library, featuring twice the amount of material listings as before with specific additions, such as new material entries for LED components. There’s also a raft of new filtering and search tools to make finding the correct material a doddle. This data can then easily be shared between team members and colleagues.

In addition, this release sees an overhaul of the meshing process. After all, the mesh is a key factor in the success of any simulation study. In particular, the new meshing algorithm will automatically refine a mesh in close gap conditions giving you an instant preview of how it will appear.

Automating the repetitive

Although the enhancements to CFdesign 2011 revolve around a small number of areas, together they represent a shift in both how the system interoperates with workhorse design tools and the efficiency of the simulation process. In the first instance we’re going to look at how your data is pushed from a 3D design tool into CFdesign in the shortest time possible.

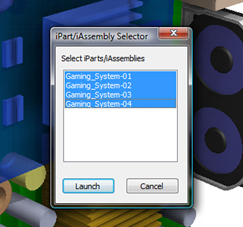

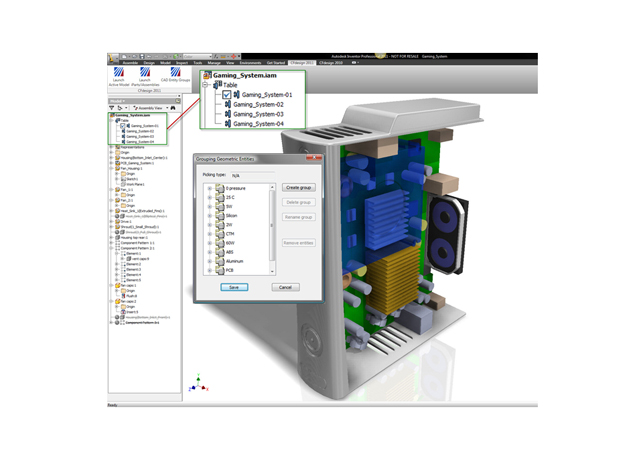

2011 introduces the concept of one click simulation and this is implemented in several areas. The most fundamental is the ability to create tools in your design system (CFdesign works with Inventor, SolidWorks and Pro/Engineer with NX support coming soon) to predefine either a part, a feature or to automatically populate information, such as materials.

For example, the new CAD Groups functionality allows you to define parts and features that represent common inputs in a CFD study (such as inlets, outlets, fluids and solids). Then when the geometry is pushed to CFdesign, these are already set-up, saving you a lot of rework.

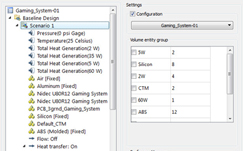

Taking this further, the new Rules Manager allows you to automatically run rules that will extract information from a 3D dataset and its associated metadata – again populating the linked attributes or inputs into the CFD study (such as material properties, load and boundary conditions). The process of creating these rules couldn’t be easier as you can either hand create them or, more commonly, carry out the process once, capture it and then reuse it.

Many would agree that for a single release this constitutes a fair amount of functionality. However, the Blue Ridge team has pushed things further enabling you to carry out all of the above over multiple studies. It’s commonly the case that any product operates within a range of conditions and parameters that affect its performance. So, in order to make the most effective use of simulation tools, you need to be able to explore the impact of this variance on your product concepts.

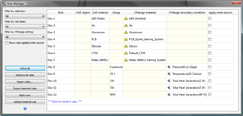

The problem is that often each study needs to be set-up, calculated and inspected individually. However, with CFdesign 2011 you can quickly build up a series of studies using the same dialogs, the same automation tools and have those executed at the same time.

Essentially, by utilising the Design Study Builder, you define the study, add the parameters for the first, clone the project, adapt the individual parameters and repeat, so creating a series of studies in a single interface. These can then be solved and reported upon as per normal.

Here is where the ground work carried out in the previous CFdesign 2010 release pays off as CFdesign already has the tools built into it allowing you to compare, cross examine and report upon multiple datasets in a single visualisation session.

To round this out, the system also allows you to store everything discussed above into templates. When it comes to simulation, one of the key fear factors for any organisation is ensuring that the results derived from the process are accurate and repeatable. By allowing an experienced team member to create templates that reflect industry best practice as well as in-house special knowledge and requirements, you stand a greater chance of making better use of your simulation tools.

Remote solving

A few releases ago, Blue Ridge implemented a cluster-based approach to solving design studies across multiple workstations. This offered the ability to use spare workstations, perhaps during downtime at evenings and weekends, to crunch through simulations quicker than if using a single workstation.

Basically, each workstation on your network runs a solver license of the code with a single machine handling the process. With this approach you may not necessarily arrive at a solution faster but it does enable you to solve multiple studies concurrently using existing hardware.

Now, with this release, some clever new tools have been added to assist with managing this process, namely with the introduction of the Remote Solver Manager utility. This not only gives you a single place to manage, move and restart the jobs distributed on your network, but with mobile alerts (either as a text message or email) you are instantly made aware of any problems if you are away from the office.

So, by logging in (using standard remote desktop technology), you can see what the problem is, make changes and set the simulation stack running again.

Interpretation and reporting

The end goal of any simulation tool is being able to derive meaningful data and information on which to base design or manufacturing decisions. The last release saw a huge amount of work enabling the user to compare, contrast and inspect multiple datasets.

This release follows that work up in several areas. For instance, there are a couple of new options for the display of flow-information, the most interesting of which is Thermal Imaging. While this might sound a little trite, it’s incredibly useful as it strips back the system and allows the user to see exactly where heat sources are and how the heat dissipates (or not) throughout the design.

Blue Ridge has been ahead of the game with its results sharing tools, which allow you to create, distribute and view a compressed version of the results display. Now, with the 2011 release, the team has further extended its result sharing offerings.

Firstly, the viewer tool is embedded directly within a web-browser. This means that you don’t need specialist tools or a client download to look and work with them. Secondly, the introduction of a data sharing facility within its customer portal means that templates, materials database and results can be shared with anyone who needs them. This follows many of the current trends in web-based collaboration and data sharing tools, such as dropbox.com, where data can be delivered quickly in a controlled manner.

In conclusion

CFdesign has been on the market for a number of years now and the Blue Ridge team seems to be working hard at solving some of the real-world challenges faced by CFD technology users today. There’s no hidden jiggery pokery behind the tool, it’s all there in a clean and simple interface with finer control for those who need it.

A good example of this ‘realism’ in the 2011 release is the increased ability to quickly set up and automate multiple studies. Then, once the data has been generated, give the user the tools to work with that data. After all, any simulation is about giving designers or engineers the data to enable them to make informed decisions during the development process.

By removing that data from a singular simulation run and presenting it in context as well as by employing easier to use tools based on reliable inputs, you’re increasing the effectiveness and relevance of your decisions. From that, only good can come.

A first class release as ever and I’m certainly looking forward to seeing what the team comes up with next.

| Product | CFdesign 2011 |

|---|---|

| Company name | CFdesign 2011CFdesign |

| Price | On Application |