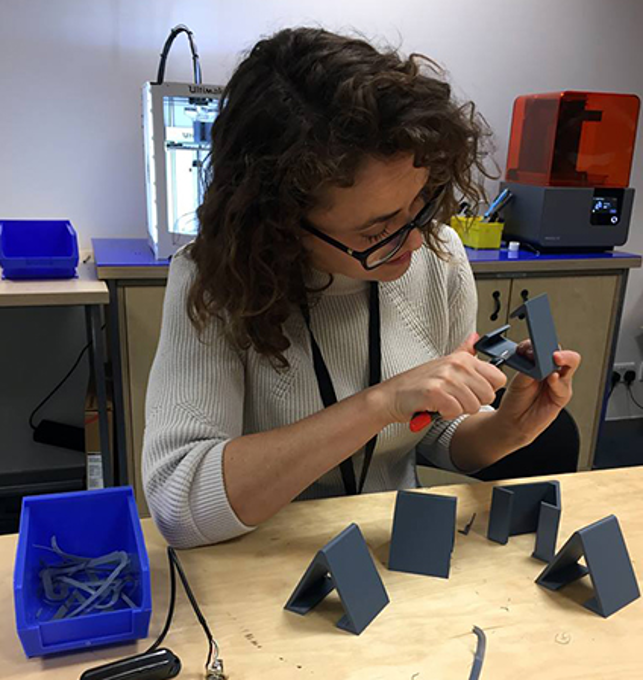

Helen testing her prototypes in the workshop space at CRL, a co-working space and accelerator supporting technology, hardware and design start-ups

Although Helen Steer never trained in engineering or product design, she is a self-taught maker who has been tinkering and experimenting with new technologies since she was a kid.

In 2016 she was a Professional Maker in Residence at Machines Room on London’s Maker Mile, before being selected to take some of her projects beyond prototypes and towards production at the Central Research Laboratory (CRL), a London-based hardware accelerator for start-ups with co-working space and a range of technologies available to its members.

In January, at BETT 2017, an education technology event held at London’s ExCeL, she launched Do It Kits, a simple and engaging way for children to get hands on with new technologies and maker methodologies specifically in the Science, Computing and Design & Technology classroom.

Towards the end of last year, Steer answered an open call from the British Council to UK makers for residency opportunities in China and, as a result, is currently Maker in Residence at Litchee Labs, a maker space in Shenzhen that specialises in maker education for young people.

D3D: How did your idea for Do It Kits come about?

HS: Last year Intel Education asked me to create a couple of prototypes and do some demos to teachers using a new version of the Arduino development board. The prototypes and associated curriculum-linked units of work I created were so well received by teachers that I decided to look into making them into a real product.

I sat down with every secondary school curriculum document and consultation paper I could find, and thought about the ways I could use making and technology to improve what teachers need to teach anyway: making lessons more accurate, more fun or more accessible. I started to believe that there was a real potential to engaging a large number of students in STEM education through making so I started experimenting with different workshops in secondary schools – and Do It Kits was born.

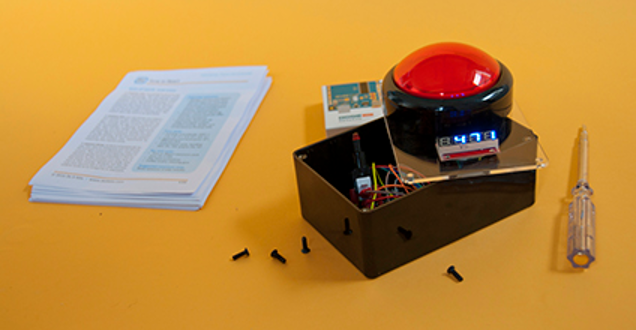

CRL helps members take their products from prototype to manufacture and here is Helen with her packaged ‘Science of Music’ Do It Kit

D3D: So, what is in a Do It Kit?

HS: Each Do It Kit comes with over three hours of expertly written and beautifully designed lesson plans, worksheets and OFSTED friendly teacher guidance with up-to-date curriculum links. Using a Do It Kit in a classroom is simple: no new skills or expensive equipment is needed. Each kit is reusable, hackable and customisable.

As an example, one of the kits is called Science of Music. With this kit, a class will make a one string electric guitar and learn about waves, frequencies, resonance, oscillation, and get an introduction to the science of music theory.

D3D: Sounds fun but possibly less fun was finding the funding to make it happen. What was the experience like of setting up your start-up?

HS: Do It Kits was entirely bootstrapped for the first nine months – all prototyping, equipment and workshops were fully funded by my freelance earnings plus a couple of (now maxed out) credit cards. When I joined CRL I got a grant of £5000 that allowed me to stop taking work for a few months so I could concentrate on the start-up.

Helen is a self taught maker

D3D: And has the experience at CRL been worth it?

HS: Moving from central East London to far West London was a bit of a culture shock but it’s been worth the commute! I have a substantial desk and storage space and the prototyping facilities are excellent. Additionally, it is very helpful to have a community of hardware and maker start-ups around me: we have unique problems to solve that a software company can’t relate to. It’s good to have others around with the same challenges.

D3D: As you’ve mentioned already, at CRL you have a range of facilities and technology available to you. Could you talk through how you make use of these in your design process?

HS: Using my first Science of Music prototype as an example, I started out making it from some scavenged wood, an old pickup from a guitar, a beer bottle, a guitar string and some nails. Once I’d made it work I’ll then think about how it will be used in class and revise my designs using tools such as 3D printing, CNC milling and laser cutting. This allows me to make a new design without investing much time or money in it – I can try it out, get very quick feedback and then revise my work as needed. This also helps me and the team at CRL to visualise any issues that will come up in mass production.

Once I’m happy with the components, I make one of each and design the packaging, again using maker technologies. I’ll use Autodesk Fusion 360 to create a test mould for vacuum forming then CNC into a two part wooden mould. This mould can then be used to quickly vacuum form internal packaging for a standard box, meaning I can create a number of dummy kits for display, demonstration and testing with almost no outlay.

A fellow member at CRL

D3D: You’re currently a Maker in Residence in Shenzhen as part of the British Council’s ‘Hello Shenzhen’ initiative. Why did you apply to this?

HS: Shenzhen has been gaining notoriety in maker circles for some years now. I’ve heard it described as “Legoland for makers” and now that I’ve been, it really is true! Electronics markets are bigger than five massive malls put together with every component, gadget, toy or bit of equipment you can imagine at really good prices. There are maker spaces everywhere with people coming from all over the world to make stuff and build products. It’s tremendous fun.

As part of the Hello Shenzhen programme I will be Maker in Residence at Litchee Lab, a maker space specifically for education. I’m extremely interested in what the British and Chinese maker education scenes can learn from each other. Of course the Chinese market is huge so I’d like to investigate how my products could work there.

In China they are reacting to the growing hardware start-up market very quickly. There are many specialist workshops – many of whom are start-ups themselves – that produce under 1,000 units at a very good price.

Even the biggest manufacturers are investing in creating separate short run facilities that are optimised to produce small quantities for start-ups. So far, I’ve found UK manufacturers uninterested in the small number of products I’ll be starting with.

The Science of Music (guitar edition) Do It Kit will introduce students to the physics behind music

D3D: Do you have any tips for other UK or western hardware start-ups that are thinking of manufacturing in China?

HS: Communication is hard. Really hard. However, the Chinese people I’ve met have all gone out of their way to help me navigate their world especially if you’ve made the effort to learn a few sentences in their language. There are a lot of rules, regulations and customs to learn about but there are ways of dealing with that such as finding an experienced agent to help you navigate the hundreds of factories and suppliers.

D3D: Being a successful start-up yourself, what advice would you give to others who have a hardware idea and want to develop it into a product?

HS: Take advantage of the wealth of knowledge and goodwill at one of London’s many maker spaces to start prototyping in. They all have their own personality so go visit a few and find the one that you click with.

Once you’ve got a good prototype I’d wholeheartedly recommend applying for the Central Research Laboratory (CRL) programme.

Make sure you know who your product is for and that you’re actually addressing a need for your target market. Making yet another shiny thing, no matter how cool, without making it for someone is almost always doomed.

The Time to React Do It Kit, which is for GCSE Biology, tests students’ reaction time whilst teaching them about neurons, synapses, ethics, human experimentation etc

D3D: You are a big supporter and champion of women in STEM. As a woman in STEM yourself, what has your experience been like?

HS: One of my big motivations for starting Do It Kits is the way students – particularly girls – respond to hands-on learning in Science classrooms. A couple of years ago I read Intel’s MakeHer report, which talks about the ways in which making is keeping girls in STEM. This strongly resonated with my own experience in various maker spaces across London. I was seeing an increasing number of awesome women coming into making from all sorts of backgrounds: designers, scientists, educators, software engineers, jewellery makers and many more. I know making and hands-on, practical activities can inspire the next generation of awesome engineers in an inclusive way.

As for my own experiences being a woman in STEM I’d say it has been largely positive. Of course there have been many low points over the years: the assumption that you’re a secretary for someone else in the room, the requests for coffee, the inappropriate come ons, the hilarious “jokes” we’ve all heard 1000 times and flagrant professional disrespect from some people.

You can’t take it to heart – I’ve developed a pretty thick skin. In any case, those archaic attitudes come from a minority of people – almost all the women and men I’ve worked with have been completely awesome.

Helen Steer on her experience and challenges of being a hardware start-up

Default