3D printing enjoys a public image built on hype, science fiction and secrecy. Having come across some relics from the past, Stephen Holmes assesses how far the technology has come and why there’s still no slowdown in sight

Moving house throws up a lot of long-forgotten items – like the lost spatula that fell down the back of a kitchen drawer or the box of charging cables for longdead devices. During our recent move, an old work bag resurfaced, and in a rush to get to an interview, I grabbed it as I raced for the front door.

Later that day, I was sat at the bar of our local pub and started pulling things out of the satchel. Business cards of long-since vanished executives, from swallowed-up businesses. A note pad, open on a page scrawled with the simple note: “Probably bullshit. Definitely expensive.”

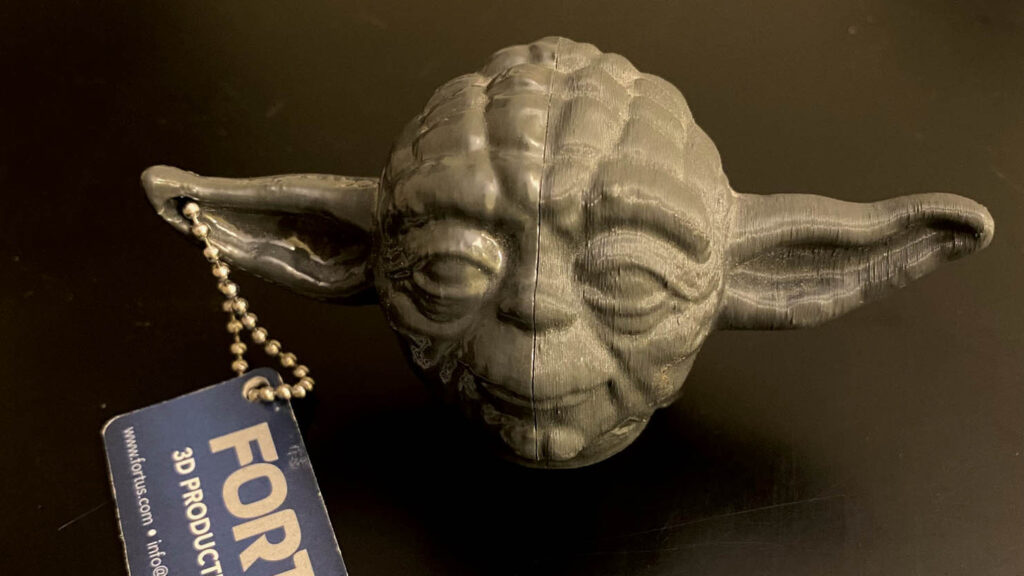

Rattling around at the bottom of the bag was an assortment of plastic and metal bits: 3D-printed samples, given away at whatever trade show the bag had been reluctantly dragged to some seven or so years ago.

Like a shot, the barman was over to examine the pile of curios, asking me, “What’s that?!”

After a brief explanation, he examined the shapes individually and asked if he could keep the Nylon bottle opener he had picked up and was examining.

“Of course you can,” I chuckled, imagining all the times he would explain to colleagues and customers the novelty of his new bar tool.

Despite it being plastic tat, it was 3D-printed plastic tat — and to this day, that still has a magical hold over people.

The ability to build something tangible, without it coming from a factory, workshop or being whittled from a stick is still a sci-fi novelty to most.

There’s a reason that desktop 3D printers always seem to crop up in the futuristic labs of movies where they’d have little actual real-world use.

Public image

Few manufacturing technologies have a public image. I doubt roto-moulding has been the subject of many column inches in the mainstream press this century. Any news about casting metals is typically accompanied by footage that might as well include stovepipe hats and street urchins.

Yet 3D printing remains fresh in the public consciousness, despite its biggest end uses being found in factories, in people’s ears and mouths, as secretive one-offs, and in sectors where low-volume, low-weight payoff is worth the costs involved.

Part of the reason lies in the school classrooms and maker groups that utilise 3D printing.

Hobbyists can use it to build their own hardware from home. When 3D printers are combined with low-cost electronics, desktop CNCmachines, sewing machines and online sites selling components and materials, incredible creative projects can be accomplished.

Education is training not only the next designers and engineers to think in 3D and with additive in mind, but also the next generation of consumers savvy to what it can achieve.

It’s fair to say that many people who have graduated high school in the time since my old bag collected its last trinkets are likely to have as good a knowledge of 3D printing as many of the people selling the technology at the trade show that day.

All together now

This month, our contributor Laurence Marks mentions that additive manufacturing is the only production technology that has had simulation capabilities around since its inception. It’s also the only manufacturing process that has popped up during the age of the internet and social media.

A cursory glance at Twitter or YouTube shows people from all walks of life and nationalities involved in 3D printing.

3D printing has maintained its allure long after the newspaper headlines stopped rolling

I don’t just mean the legions of folks building natty figurines on swathes of same-but-different FDM machines – each to their own, I suppose. There’s also some really inspirational stuff done by people who have proper day jobs, who in their spare time produce everything from incredible custom costumes (@sophywong) to giant LEGO go-karts (@mantisrobot). Questions get asked, advice is offered, interactions are established and collaborations take shape.

None of this changes the fact that other methods of manufacturing are still king, and will remain so for a long time to come. Yet, 3D printing has maintained its allure long after the newspaper headlines stopped rolling.

The hype was overblown, but the technology has never ceased to move forwards, and in the time since, the user base has grown exponentially. It will be interesting to see how 3D printing is thought of in the next seven or so years — though I sadly doubt it will still earn me a free pint in 2028.