A lack of adequate staff training is a common weak link in the adoption of additive manufacturing, but with smart thinking and investment, it can be one of the simplest issues to solve, writes Rich Wetzel of The Lanterman Group

Additive manufacturing (AM) is no longer a new technology – and we need to stop treating it as if it is. If we don’t, it will keep catching us by surprise. As with any production-grade technology, it only makes sense to invest in AM when investing in the entire workflow. Otherwise, it’s a recipe for failure.

Organisations investing in AM systems often underinvest in the skills and procedures that make them productive. As an industry, we must build up AM capabilities by building up the people responsible for them. In production, ‘good enough’ is never adequate.

We see this all the time, as AM moves from 3D printing for prototyping purposes to building molds, tooling, fixtures, final parts and other mission-critical structures. Rising rates of standardisation mean organisations expect better of parts, whatever the technology used to produce them.

If AM-made parts aren’t good enough, end users and others in the supply chain will reach the false conclusion that AM itself isn’t good enough. It’s time to face that gap and to work out best practices designed to bridge it.

Manufacturing, at its best, is boring – predictable, repeatable and reliable. All the things, in short, that manufactured parts must also be

Boring is beautiful

Manufacturing, at its best, is always boring. Boring is predictable, repeatable and reliable – all the things, in short, that manufactured parts must also be.

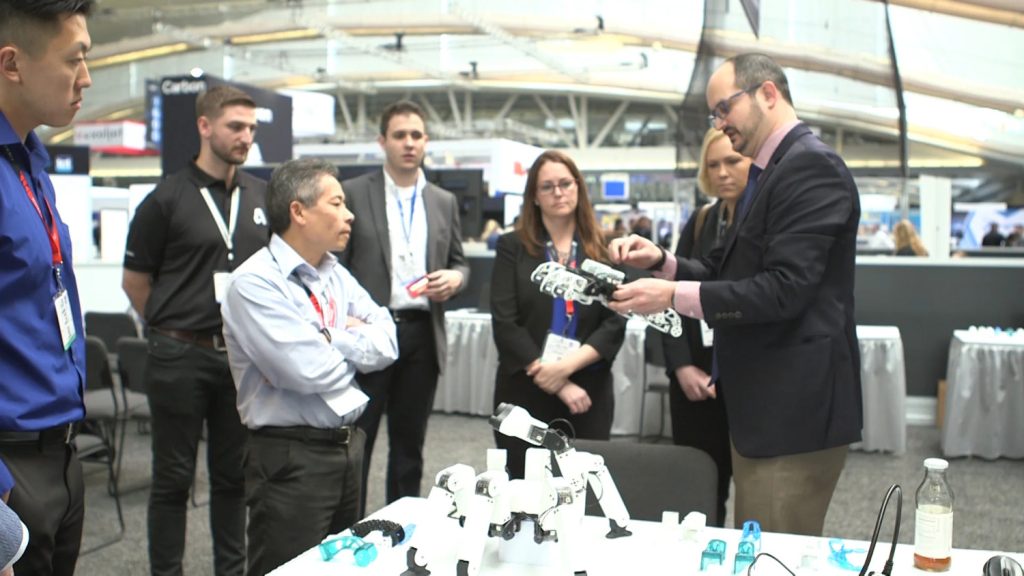

A good AM work cell looks boring. Builds begin on time, the standard test part sits nearby, and hand-offs between workers happen seamlessly.

When an error occurs, they know how to recognise it and what to do next. This is the result of a structured approach to people and process, which starts with investment in training.

The more AM falls under this umbrella, the more realisable the technology and its goals will be.

Training is often treated as a single event, and typically comes in the form of a vendor demonstration, with the assumption that proficiency in the process will follow. From there, daily practice is overshadowed and reliance on a few expert individuals becomes daily practice. This is an unfortunate reality experienced by many firms that didn’t invest in structured, skills based training.

This lack in training is one of the single biggest weak links in the AM chain – and one of the simplest to address to turn performance around.

Developing skills is one thing, but repeatable success in AM depends on different people making the right decisions at the right time. Specific roles require different types of training content and in different formats. For example, a designer would certainly benefit from instructor-led training when learning a new software, but a manager may receive more value from asynchronous online training. Organisations should build pathways to meet each role where the work actually happens.

To create scalable, repeatable successes, they should approach team training the same way. That means documenting successes and failures throughout and integrating these situations into refreshers for the team. Let training continue building upon a foundation, wrapping lessons learned into ongoing education.

At The Lanterman Group, we have seen measurable success among teams that approach their training with the same care that they devote to every other aspect of their end-to-end workflow. We’ve developed real-world tested training plans that target measurable goals, using blended learning that focuses on skills development for specific roles.

Interactive online modules, digestible content, asynchronous offerings and virtual reality are just some of the remote, yet hands-on, approaches that we’ve found effective.

Training budgets

People don’t become proficient in AM by attending a single training day. They get good by doing the work and putting in the practice in a way that’s enabled by the leaders of their organisation.

Take Ohio-based Humtown Additive, for example: the company built a capability around 3D-printed sand cores and moulds, scaling binder jet production and earning global recognition as an industry leader. Its success can be attributed to its investment in talent development and culture initiatives that treat learning as an operating system and not a one-off programme.

Your entire AM production flow remains dependent on a few individuals. Avoidable failures will occur, safety is compromised and quality varies by shift. This isn’t inevitable, but it shouldn’t come as a surprise, if training is treated as an afterthought.

Why invest in AM without investing in the expertise needed to use and manage expensive equipment and materials? That’s tripping at the (very costly) finish line, when what you should have done is more training before the race. Let’s approach the AM race like we mean to win it.

About the author:

Rich Wetzel is president of The Lanterman Group, a Chagrin Falls, Ohio-based consulting company that focuses on building the AM workforce through expert-led training.

Wetzel has worked with organisations including America Makes, the US Department of Defense and Youngstown State University

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here