Lightweighting and topology optimisation are great, but if parts can’t be qualified, then who is to blame when things go wrong? Our columnist SJ finds something to ‘clack’ about, while tackling AM gyroids

ASMR, or autonomous sensory meridian response, is a term that describes the sedative sensation of sounds that send happy tingles cascading through the body.

A few of my much-loved ASMR sounds: the soft crackling of freshly baked bread as you tear it open, the barely audible flutter as you turn the page of your favourite book, and the triumphant ‘clack’ as I place a part on my boss’s desk that he told me was “unprintable” the week prior.

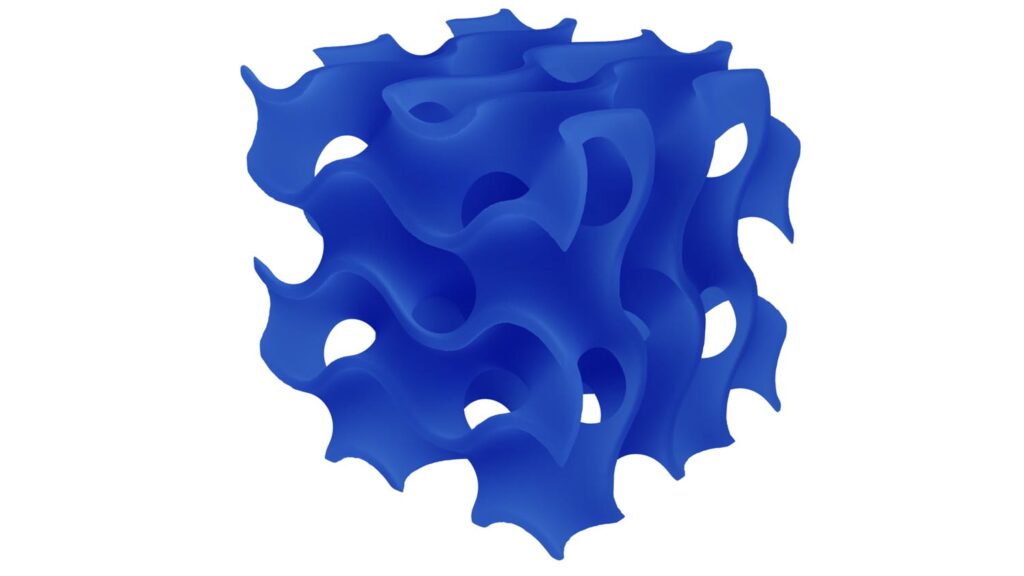

The ‘unprintable’ part was a gyroid, one of my greatest loves. The gyroid was invented in the 1970s and is described as an infinitely connected Triply Periodic Minimalist Surface (TPMS). TPMS structures have a higher surface-to-volume ratio than common strut-based cellular structures, which can be tailored to suit specific engineering design requirements to enhance mechanical performance — think energy absorption for ballistics or heat transfer or lightweighting to remove material.

But the general public may not be familiar with them, given how challenging they were to manufacture before the onset of 3D printing.

Gyroids are my favourite structures, but there’s more than one way to lightweight a part. Strut-based latticing and topology optimisation are the other two underutilised design resources to reduce the amount of material in non-critical areas of your part.

I see the greatest success with strut-based lattices in the medical sector, where we can 3D print implants with better osseointegration, since the porous structures more closely mimic those of anatomical bone. The porous nature of the lattice allows nutrients to flow through and around the lattice structure to aid in soft tissue and bone growth. (Mimicking nature’s biological designs? I’m getting that ASMR tingle again.)

Topology optimisation is where 3D printing truly shines, as a part has its shape optimised for the given design space and a given set of loads, boundary conditions and constraints

Topology optimisation is where 3D printing truly shines, as a part has its shape optimised for the given design space for a given set of loads, boundary conditions and constraints. Additionally, it allows you to efficiently combine multiple parts into one, while also reducing the amount of material required for your design. And that saves you not only cost, but time as well — especially if your organisation has invested in AI and machine learning.

Nails on a chalkboard

As I stood there with a smug ‘I told you so’ grin on my face, clacking my gyroid cube on his desk, my boss asked: “And how do you know it is sound all the way through? How can I trust that every point is where we think it is and that all the nodes are connected – even in places we can’t see?”

My genius reply? “Uhhh…that’s a great question. I’ll get back to you.”

I took upon the Sisyphean task of asking “What’s your favorite lightweighting method?” (or some variation thereof) as my networking ice-breaker for the ASME AM Industry Summit in June.

To my surprise, 70% of the audience response cited topology optimisation. I asked a similar question at my very first Additive Manufacturing Users Group (AMUG) back in 2015, and the overwhelming response was strut-based latticing.

So, I wondered, was this based solely on what was trendy in the media, or was there something behind it in the design or manufacturing space that I had missed? On Day Two, I followed up with a second round of questions and was able to discern that, like my boss, most of the higher up design decision makers were uncertain of how to tell if lattices were sound. This uncertainty was rapidly hindering adoption of the technology. But where is all of this uncertainty coming from?

Opportunity clacks

Misophonia can generally be described as a decreased tolerance to specific sounds, triggering reactions such as anger, annoyance or the fight-or-flight response. In a business context, it can be summed up in one word: Liability.

If something goes wrong with a part that has been lightweighted, who falls on their sword? Is it the owner of the design? The owner of the printer? The printer manufacturer? Or does it fall on the owner/ licensor of the print software?

Lightweighting could change business strategies across multiple sectors. As the technology grows, we can offer shorter lifecycles, greater customisation and more sustainable practices.

However, if we were to impose liability on the printer manufacturer for any product the printer could potentially produce, we’d be creating excessive liability and damage the business case for 3D printing.

After a long night reading papers on latticing, trying to find the answer to my boss’s question, I was early to work and making coffee when I overheard two members of our NDT team discussing the new CT software they were trying out.

They were debating which demo part they should scan first. The grin slid easily back onto my face as I turned to them, coffee in hand, and said, “You fellas looking for a demonstration piece?”

My other hand reached into my work jacket and tossed it across the table, where it landed with a very satisfying ‘clack’.