Companies that design and sell customised products are under pressure, especially in the engineering department.

Engineers are squeezed to create proposal documents and drawings as fast as possible. This can lead to best-guess costings for orders that aren’t even guaranteed.

Engineers are creative people, but their talents are often wasted on tasks that could be automated.

They have less time to re-engineer existing designs, update drawings and carefully check every detail.

Jobs are thus left vulnerable to errors, rework, backlogs and delays. All of this is not only frustrating, but it can also affect profit margins and damage reputation.

By automating time-sensitive and often repetitive upfront activities, companies have more time to innovate and add value to product designs.

Throughput is increased and quality improves, resulting in higher productivity and better business.

Imagine you are selling a product and, every time you sell it, it changes in some way, shape or form.

Designs are invariably based on a standard theme, or variations thereof, but the actual result is different for each enquiry or order. In short, other people are specifying customised versions of your products.

However, the sales process for custom orders can take some time. It often requires extensive product knowledge.

It could involve other people: sales executives, dealers, distributors or even endusers themselves. Typically, in business-to-business sales, you need to discuss technical specifications.

Being able to show visual results is also a real advantage – and it could be a two-way thing, because you need feedback too. You, and they, need to make sure you’ve correctly interpreted what they are looking for.

Another caveat is that, in a global market, you may need to travel, viruses permitting. And let’s not forget the need to reduce your carbon footprint.

There’s so much to think about! Now imagine if your process was digital, and if some of it was automated.

You could guide others through the choices available; you could help them decide on features, sizes, colours, service contracts and so much more.

Imagine that the data that is collected through a guided selling process is used downstream, with intelligence and with rules and with knowledge built in, too, so it automatically generates all the design and manufacturing data

Imagine if all that collaboration took place in the digital world. Maybe it’s online, embedded in a website; maybe it’s in virtual or augmented reality.

Now you can communicate without having to be next to each other. Now you can sell around the world. Now you can sell in places you otherwise wouldn’t.

Now imagine that the data that is collected through that guided selling process is used downstream, with intelligence and with rules and with knowledge built in, too, so it automatically generates all the design and manufacturing data.

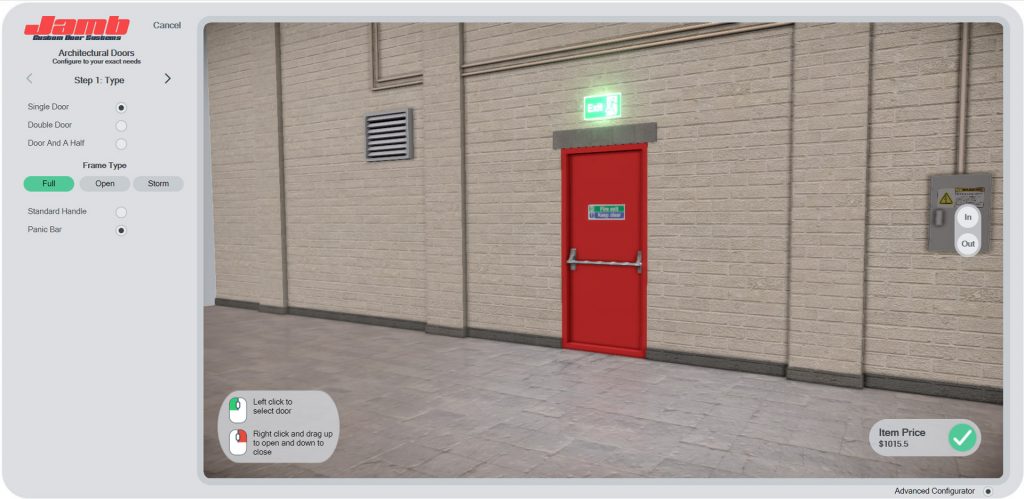

A company I met some years ago in the US, a manufacturer of steel doors, has taken this approach and not looked back.

It processes hundreds of enquiries and orders each week. Each one is different in some way.

The doors need to fill a different structural opening. They could be fire doors or security doors. Each one has its own particular use. The order could be for a single or a double door, with a panic bar or maybe a toughened glass window.

In short, the options are numerous, and there may be specific conditions that apply.

This company has automated its front-end and back-end systems. It sells and manufactures digitally. It has automated its complete design-to-order process. Generating all that data – that’s the bit that takes time.

CAD files, BOMs, quotes, cutting lists, the things the company needs to buy in. It’s a lot of data.

All company systems are automatically populated, because everything is based on digital data. What this means is there is now a way of doing business anywhere.

No geographic restrictions. A worldwide market. It doesn’t matter how niche or custom the product is.

Digital information is created automatically. And because it’s created based on company knowledge and design rules, it’s all available in the system.

In our personal lives, we’re so used to searching for what we want online. We configure and buy trainers, computers and so much more. People in industry want that, too.

About the Author:

Glen Smith is CEO of DriveWorks.

We’re not too sure what’s cooler: the fact that he’s recently been to Buckingham Palace to receive two Queen’s awards (for Innovation and Enterprise) or that he’s considering getting his 13-piece soul band back together.

Get in touch @driveworks