Imagine you’re running a successful manufacturing organisation and discover yourself in the middle of a management buyout. For many companies, this doesn’t present too much of an issue, other than paper work, signing a cheque and moving on to bigger and better things. But when you’re involved in the design and manufacture of complex products and have established practices and tools, management buyouts can lead to software licensing issues which can become an unexpected problem.

At the same time it can also be an opportunity, because when change is in the air, it’s the best time to re-evaluate what you’re doing, how you’re doing it and choosing the most effective tools to the job done.

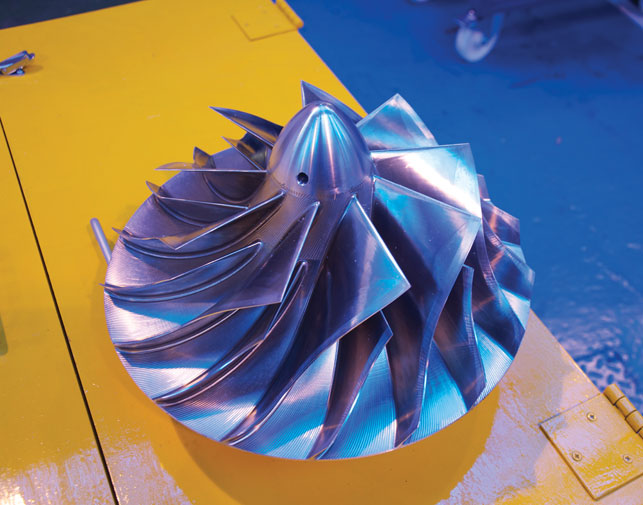

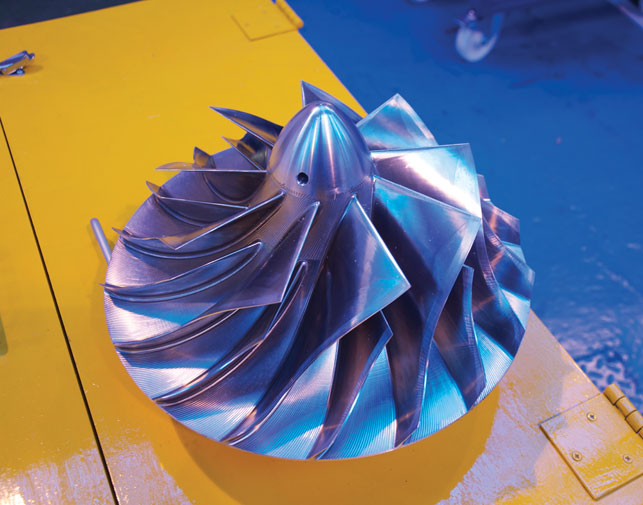

Napier Turbochargers manufactures all of its core components in-house, including this compressor wheel

This is the position that Napier Turbochargers finds itself in today. The company has a rich heritage of innovation within many fields, but the last few decades have seen the Lincoln-based firm concentrate on its competency of the design, manufacture and support high efficiency industrial turbochargers, used across a range of markets including Marine Power, Rail Traction and Power Generation.

Having been through a buyout from the Siemens Turbo-machinery organisation, the design and manufacturing team is part way through the process of re-assessing how it develops its products, what tools it uses and how the process can be made more efficient.

When under the Siemens umbrella organisation, Napier adopted Siemens NX as its design tool of choice to conform to company policy and used Teamcenter to manage its product data, along with a range of CAM systems for NC programming. However, following the separation from Siemens, the company has found itself in the position of having to renegotiate its contracts for NX and Teamcenter from scratch and was led to the door of Majenta PLM.

In consultation with Majenta, the team decided to maintain its NX usage and adopt Teamcenter Express for data management as they had before. What differed was how Napier decided to extend the use of the system beyond the design office and into the manufacturing department and factory floor.

Complexity as a design challenge

Turbochargers are a complex beast. Whereas a naturally aspirated engine uses only the downward stroke of a piston to create an area of low pressure to draw air into the combustion cylinder, turbochargers are used to compress the gases to create a greater mass of oxygen within the combustion cylinder.

Turbocharger external casings and internal aerodynamic components are customised to suit the engine type and configuration

The additional oxygen makes it possible to combust more fuel hence increasing the engine’s power and torque. Napier operates predominantly in the marine, rail and power generation sectors, and as a result its products are generally of a much larger scale than those used in automotive.

The Turbochargers that Napier develops are far from standard. With a wide variety of engines to integrate with, and differing packaging and installation limitations, there are many complex variables that influence the design.

However, this doesn’t mean that every design starts from a blank slate built up with bespoke components, as Ian Pinkney, Chief Design Engineer at Napier explains. “It’s a family of products, but an extended one,” he says. “Is it customised for the end user? Yes, it is, but from a selection list. The one thing that we’re matching to is the performance of the turbocharger for a given frame size and there are a lot of options for any particular frame size – so it’s not an off the shelf product.

“The frame size can have four different turbines as an option,” adds Pinkney, as he explains just how many different combinations of components can go into a single design. “There are around eleven nozzle sizes depending on the capacity of turbine, four to five different compressor capacities, two different compressor designs and a range of matching diffusers. In terms of installation, the turbocharger casings can be indexed to suit the engine pipe-work and equally, the turbine inlet casing is commonly customised to the end user.”

The process of matching engine performance to the turbocharger is done by the Application Engineer department, which selects the parts required. But from a design point of view, Napier starts out by looking at the target market, and the performance range that’s needed to cover for those engines.

With so many variables, it’s clear that a powerful 3D design technology is essential for the development of these complex products, but there are still many challenges to overcome.

Challenge and benefits of 3D

Napier has a long history of using NX, and its team is very experienced in using it in a 3D design context, but there are still areas in which the company finds challenges. According to Pinkney, this often stems from the multitude of ways to accomplish a single task. “Within all CAD packages, there are different tricks and work arounds,” he says. “Even with our models, there are certain things that prove difficult and challenging just to get the model to do what you want. From my point of view a question of interest when truly designing in 3D is ‘how much does the package you’re using influence your design?’ Do you end up with a design that’s influenced by what you can model, rather than truly being what you intended.”

Pinkney doesn’t regard this as a negative, but rather part of the challenge of working with 3D. However, compared to the company’s 2D AutoCAD-based past, working in three dimensions brings all manner of benefits, which seem to be summed up nicely with a single word. Clarity.

“One of the most interesting things about working with 3D is that you’re more likely to come up with a new design because you can see exactly what’s going on and can describe it more easily – and discuss it. That’s something that gets missed,” Pinkney enthuses. “It’s much easier to discuss a 3D part on screen; it certainly brings more people into the loop. With 2D, it was very easy for us to forget that not all are as comfortable or necessarily as skilled at interpreting 2D images as solids components. 3D takes away a lot of the ambiguity.”

With a highly experienced team, many might assume that a company like Napier would operate with a hierarcy of design engineers with draughting staff to detail their work, but Napier, along with most organisations in Europe is bucking that age old differentiation. Pinkney feels that the days of the draughting department are long gone, and while draughting responsibilities are shared out amongst the team, the original designer tends to follow a project through to completion. When it comes to future modification however any designer may pick it up.

This represents a challenge for Napier, as Pinkney explains, “There are thousands of ways to model a component. As you increase complexity, more options present themselves. Design change often requires more experience from the operator; to modify something that already exists rather than to model from scratch. You really do have to understand how the model was constructed in the first place to be able to modify it, particularly when even the simplest of modifications can as a modelling exercise prove quite difficult.”

Napier is currently looking at Siemens’ Synchronous Technology, but with the complexity of its data, and the performance driven nature of its designs, it’s yet to gain great use within the organisation, but as Pinkney points out, “CAD software is a lot better than it used to be, but it is still the designer’s skill in using the package that counts.”

Alongside its continued usage of NX, Napier is also working with Majenta to implement Teamcenter, not only to centralise data and ensure that the team has access to the most up to date information, but also to handle workflow and sign off processes in a controlled and structured environment.

“We are in the process of defining our Teamcenter Workflow to better handle tasks, both within the design and manufacturing departments, in particular tracking a part’s status,” says Pinkney. “When looking at product data management, it’s not just about hard data but also about keeping our schemes and ideas together which can easily get fragmented. Harder still is capturing design experience/expertise.”

Simulation

Simulation has become an essential tool to help Napier maintain its advantage. The team has a mix of off-the-shelf analysis simulation codes, in-house developed tools, and more task specific software. Napier specifically carries out extensive Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) analysis for the aerodynamic and rotating components, but also employs FEA for static parts.

The team uses a combination Ansys (for FEA) and CFX (for CFD) and with its new technology platform, has adopted the NX module that allows preparatory work to be done within NX, before the models are sent off to the simulation team. Alongside these general-purpose tools, Napier also uses specialised software for engine and gas dynamics simulation. This comprises in-house developed tools and external commercial applications.

NX from Siemens PLM Software is Napier turbocharger’s tool of choice for design

Manufacture

Once a design is ready to move to the next stage, the manufacturing team kicks into action. At present, Napier has a mix of both in-house and outsourced manufacturing. While Napier concentrates on its core competency and specialism it sub-contracts out other work (such as nozzles, bearings and some cast casings).

According to Jon Riggal, Senior Manufacturing Engineer at Napier, “In-house manufacture is essentially rotating parts. We do build some casings and while the capability is there in-house for both those and the diffusers, it’s really more a case of managing workloads and productivity and more a purchase driven decision. “The key competencies are the rotating components and we keep those in-house under our own control,” he adds.

The lines between design engineering and manufacturing engineering are going to blur in terms of what models are provided

The move away from Siemens Turbochargers has given the manufacturing team the opportunity to re-assess and revamp how they currently work. A legacy CAM system is in place, but plans are underway to move the NC programming work to NX CAM as projects permit.

Riggall feels that the main driver for this move is being able to use 3D models direct from the Design team, whereas previous workflows saw too much reliance on paper drawings and, in some cases, complete rework from scratch to create 3D models for manufacturing.

“None of the systems we’ve had in the past, or are currently running with, are integrated into the design packages so it’s a very laborious long winded process to go from Design to Manufacture to produce NC programs,” Says Riggall.

This represents a challenge for both Design and Manufacturing to reconcile their different requirements, as Ian Pinkney explains. “What we provide will be key. The lines between Design Engineering and Manufacturing Engineering are going to blur in terms of what models are provided. If a model is going to be manufactured, what do the guys in manufacturing need and how should that model be constructed? Perhaps intermediate models for manufacturing rather than just finished part models are produced in the design area? Do we produce drawings and manufacturing layouts at all? These and other questions are raised when we step back and look objectively at what we do.”

If there are no drawings, how does the company envision that critical, non-geometric manufacturing data will be communicated? The team believes that Product Manufacturing Information (PMI), a term for storing annotation on a 3D model, holds great promise and will sit well with manufacturing.

Looking to The Future

The team at Napier Turbochargers is keen to get up and running in its new environment, but such implementations have to be managed carefully, as there are live projects underway.

The Design team already has NX up and running, but with a history of using the system, this should come as no surprise. Teamcenter is in use in within design and Pinkney feels that this solves one of the age old problems of multi-user teams and data distribution. “Data used to be stored on people’s home areas and a local drive and sometimes, in different CAD packages. Teamcenter will undoubtedly help with that,” he says.

We’re such a small team in manufacturing and being able to devote enough time to bring a new system on board is quite difficult, having live projects that need completion

In the manufacturing department, the NX CAM implementation is proving more time consuming. “As we stand here today, we’re not currently using the manufacturing system because it’s a completely new animal and we’re very conscious of getting everything in place; naming conventions and the like in Teamcenter,” explains Riggall.

“We want everything to be right and our team to be trained and skilled in its use before we come to use it on a live basis. And we’ve still got our existing system to fall back on. We’re such a small team in manufacturing and being able to devote enough time to bring a new system on board is quite difficult, having live projects that need completion.”

The final question for the team at Napier is how is it going to use this technology platform as the basis for improving both its products and business efficiency moving forward? Does a more integrated approach to design to manufacture give its team an edge and where is that edge derived from? Is it just a question of time saving? Ian Pinkney picks up the thread, “It’s everything. Time comes into everything you have to do. The more time you can save, the more time you have to explore different designs.”

“Obviously we have a certain date by which to get a product manufactured and to the customer, without which an engineer could spend five years optimising a product, doing all sorts of experimentation. But, at some point, you have to decide what you’re going to do and get it done.”

Collaboration and IP protection

Working within a supply chain represents a challenge for any organisation, whether it’s up at the top or down in the lower tiers. Each has its own pressures and problems. One thing that is becoming a huge concern with many organisations is the quandary of needing to more effectively share data with partners in design and manufacturing, whilst ensuring valuable intellectual property in 3D product models is protected. Napier is currently in the stage of evaluating several approaches and technologies to solve this problem.

When it comes to sharing information with both suppliers and customers, Ian Pinkney sees the use of 3D models as key, but within a controlled manner. “We’re looking at producing simplified and lightweight models in a variety of formats,” he says. “Certainly in terms of installation, many of our customers don’t need a full description. With a turbocharger, there’s no real reason for them to have the full detail just the interfaces. Plus, if it’s an engine manufacturer, they already have a very large model and they don’t need a full turbocharger model adding to their file sizes.”

The team has been using JT data for some time and while this lightweight format is becoming more common, it’s often the case that there’s an element of education as the customer might not always be aware of it. Napier is also looking at 3D PDFs for visualisation, if not data exchange. In terms of the mechanism used to share that data, Napier is investigating ways to provide access to this type of data using the web and is currently looking at both Teamcenter and some form of Microsoft SharePoint set-up to manage its models externally.

Napier rethinks its product development and manufacturing processes