The European Space Agency has been experimenting with adding a natural fibre that once wrapped early Egyptian mummies and was worn by Roman aristocrats to its satellite body panels.

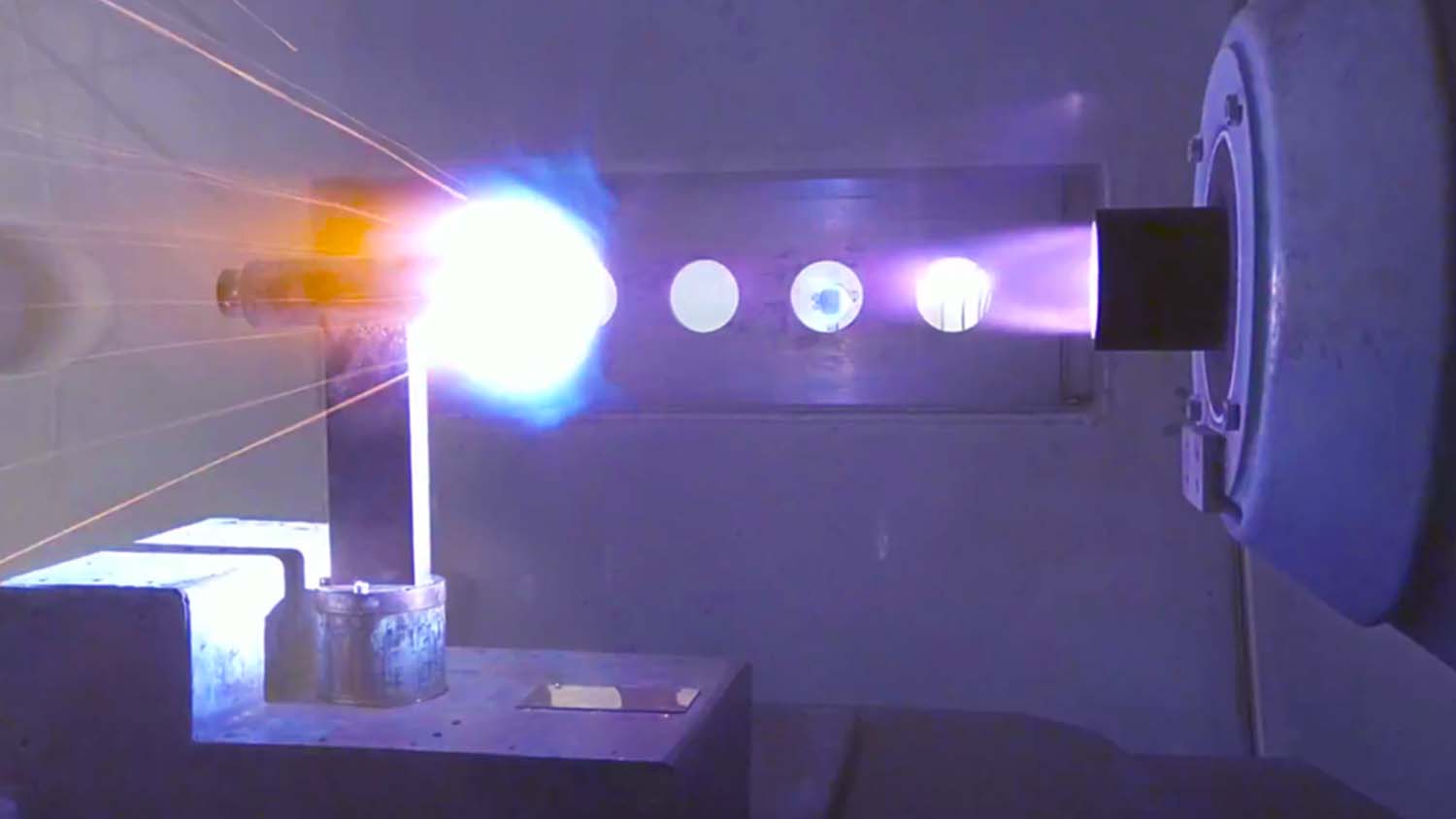

Threading fibres from the flax plant – most commonly used to make linen – through panel material can help space missions burn up more rapidly during atmospheric reentry.

This makes the material combustion happen faster, meaning safer disposal for people and property on the ground.

An ESA project with Swiss companies Bcomp and RUAG looked into substituting flax fibres for carbon fibres, which are employed to make carbon fibre reinforced plastic.

“We found that they have exceptionally low thermal expansion – which is good in terms of the temperature extremes of orbital space – as well as high specific stiffness, and strength which can be retained right down to cryogenic temperatures,” says ESA materials and processes specialist Ugo Lafont.

“They are also able damp down vibration well, can endure ultraviolet radiation exposure and impede radio signals much less than carbon fibres.”

ESA structural engineer Tiziana Cardone, explained that there were two main reasons behind the project: “Firstly to reduce the environmental impacts of space manufacturing, which is one of the main goals of ESA’s Clean Space initiative. Our detailed Life Cycle Analysis shows this can cut the carbon dioxide emissions by up to 75 per cent compared to matching carbon fibre parts.

“In addition, in another link to Clean Space, we’ve been seeking out novel materials that can ‘demise’ more easily, meaning they can burn up more rapidly and completely during atmospheric reentry. This has been driven in turn by the requirements of Europe’s space debris mitigation policy, requiring a less than 1-in-10,000 risk to people or property when satellites are disposed of at their end of life.”

The ESA’s detailed testing of this natural fibre composite has helped it find wider terrestrial uses in turn, including inside McLaren Racing’s Formula 1 cars and with Sweden’s Volta Trucks.

Volta is using the composite for weight-saving and more environmentally friendly body panels, while McLaren Racing has collaborated with Bcomp to manufacture Formula 1’s first natural fibre composite racing seat.

Possessing improved vibration-damping properties to a traditional CFRP seat, the new material also offers wider safety possibilities, with carbon fibres notorious for splintering during accidents, puncturing wheels and potentially injuring drivers.

At the end of the seat’s life, for example, it can be ground down into a new base material or thermally recycled without residual waste, rather than end up in landfill.

“We’re a small team, and working with ESA has taught us a lot,” adds Régis Voillat of Bcomp, “which we’ve been able to apply in turn to a lot of our other projects. So this collaboration has supported the spread of sustainable technologies to other sectors as well.”