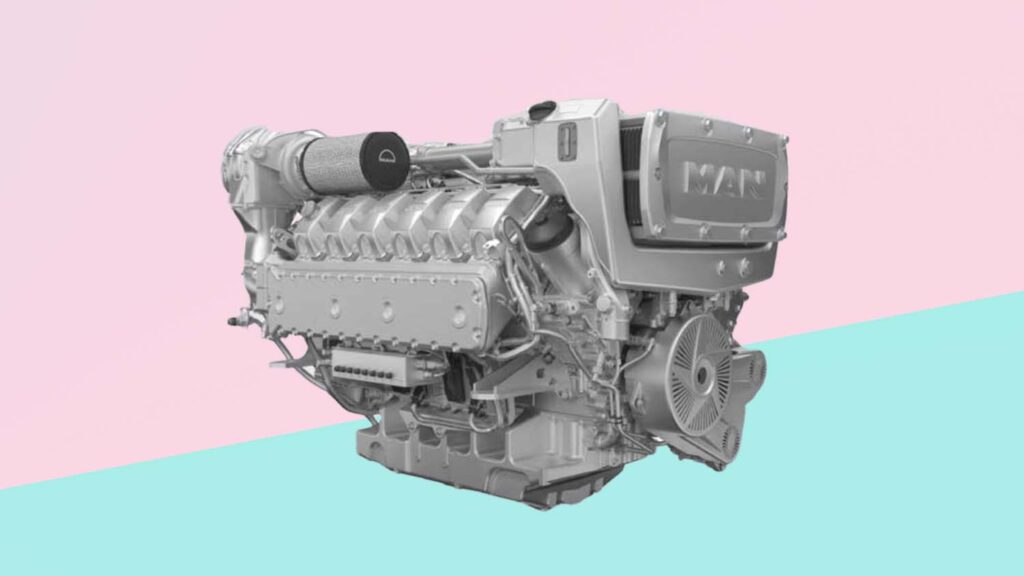

MAN Truck & Bus has explained how it has began to tackle spare parts management by using digital inventory management and manufacturing, following the need to urgently provide a part that it was no longer in production, storage or with available casting tooling.

Faced with having to provide 10 bronze water cooler manifolds that no longer exist for a marine engine, it managed to fill its need for this short term demand by working with digital inventory and 3D printing experts Replique to reverse engineer and manufacture the part to exacting tolerances and mechanical requirements.

The collaboration saw Replique take the part and a manufacturing drawing to build a 3D model of the manifold that could then be 3D printed. The team then selected a material that was technically equivalent to the original material, in this case a bronze alloy for SLM 3D printing, m4p Brz10.

Using Replique’s network of more than 85 partners worldwide, a local production service was enlisted, providing MAN with end use parts 7 weeks from its initial enquiry.

Tensile tests conducted at MAN’s Central Material Technology department revealed that the chosen material actually exhibited better technical properties than the original. The use in practice of these parts was also successful, leading to an additional order for 10 units.

The 3D printed bronze manifolds surpass the requirements of the original part. Due to the digital availability of production information, they can be reordered at any time with consistent quality measures in place.

Following this initial collaboration, MAN aims to undertake further projects in the future, using a digital inventory to help reduce costs and further optimise its after sales and spare parts logistics service globally.

“The collaboration with Replique was seamless from our initial contact to the moment we received the finished parts,” states MAN spare parts logistics manager Thomas Hauck. “It allowed us to promptly assist our spare parts customers, and we are already in the process of realising another 3D printing project with Replique.”