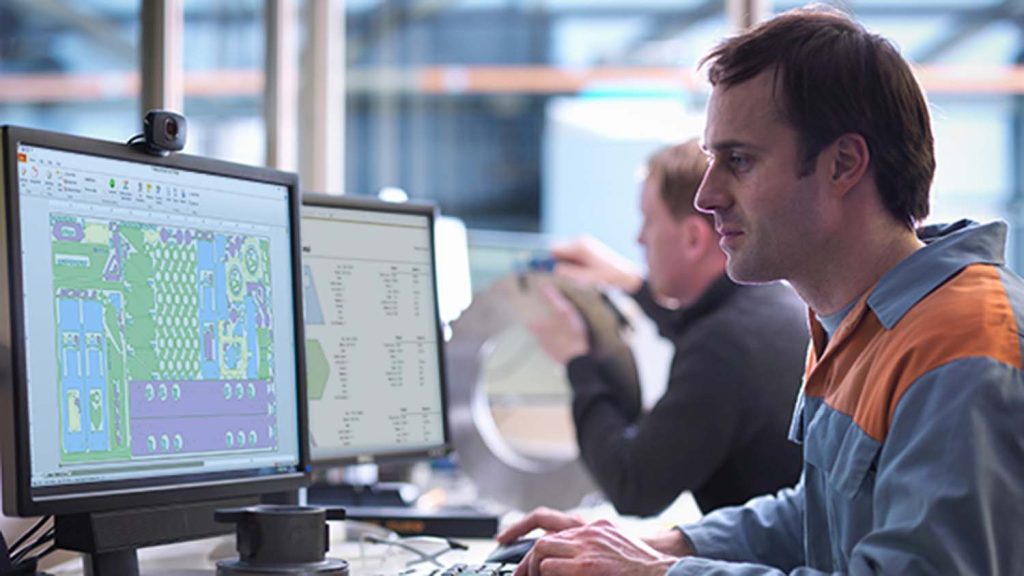

Hypertherm has announced the release of ProNest 2023, its CAD and CAM nesting software for automated cutting.

The US-based manufacturer of industrial cutting systems and software said this new release contains new features and enhancements designed to help customers improve their operational efficiency while reducing non-value-added tasks.

ProNest 2023 should include full functionality for Plate Saver, a Sure Cut technology that combines the arc stability of X-Definition plasma with specialised software parameters to increase material utilisation when cutting mild steel.

Hypertherm said this update also contains enhancements to ProNest’s Production Manager, a web-based module that integrates with Hypertherm’s Edge Connect CNC to automatically capture real-time machine data.

Enhancements should include the ability to edit production times for completed nests, set job status changes, and search for nests by customers.

According to Hypertherm, the software contains a feature that merges XPR setups, so it should now automatically detect and merge changes made to the process parameters or bevel spreadsheets into a new setup during installation.

Customers should be able to choose to use their existing customisations or the latest factory cut charts.

Finally, Hypertherm claimed the software is even easier to use as it includes a new welcome screen and customisable ribbon.

The welcome screen should contain an informative dashboard that highlights training videos, application tips, and other valuable resources, while the ribbon allows users to add, remove and rearrange tabs.

Customers should be able to save different ribbon configurations and switch between them as needed, to best fit their workflow.

“Our software developers have really focused on reducing the waste inherent in most cutting operations,” said Hypertherm product marketing manager Tom Stillwell.

“Features like Plate Saver do this by maximising the number of parts on a plate so customers have to buy fewer plates and waste less metal. At the same time, the internet of things has allowed us to make great strides in manufacturing automation. Data that we’ve never had before is now easily at our fingertips,” he went on.

“Tools like our Production Manager Module will help customers look at their operations more holistically, providing insight to help them work smarter, faster, and more profitably.”