DyeMansion has expanded the parameters of its VaporFuse for different levels of smoothing using its Powerfuse S industrial post-processing system.

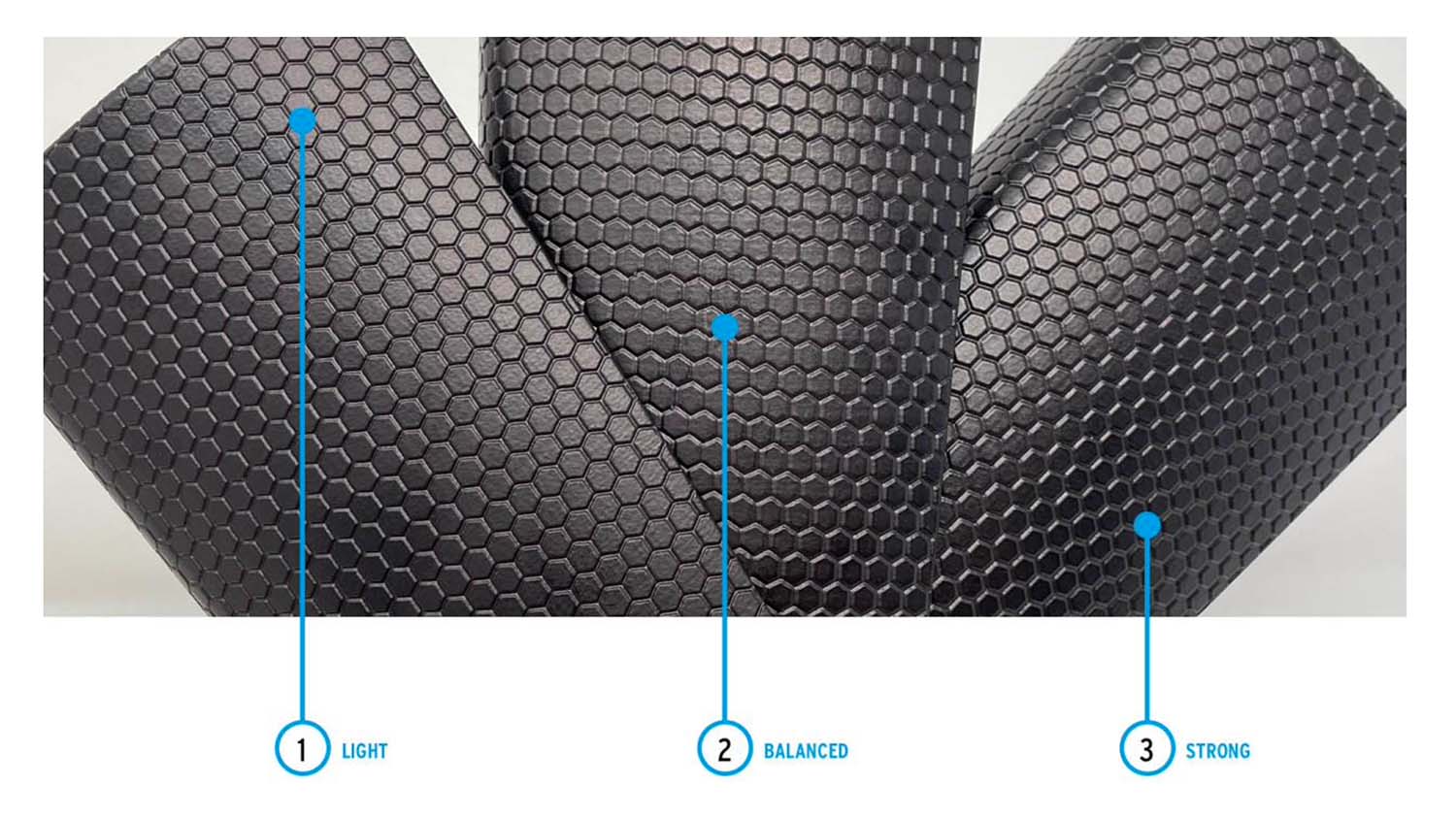

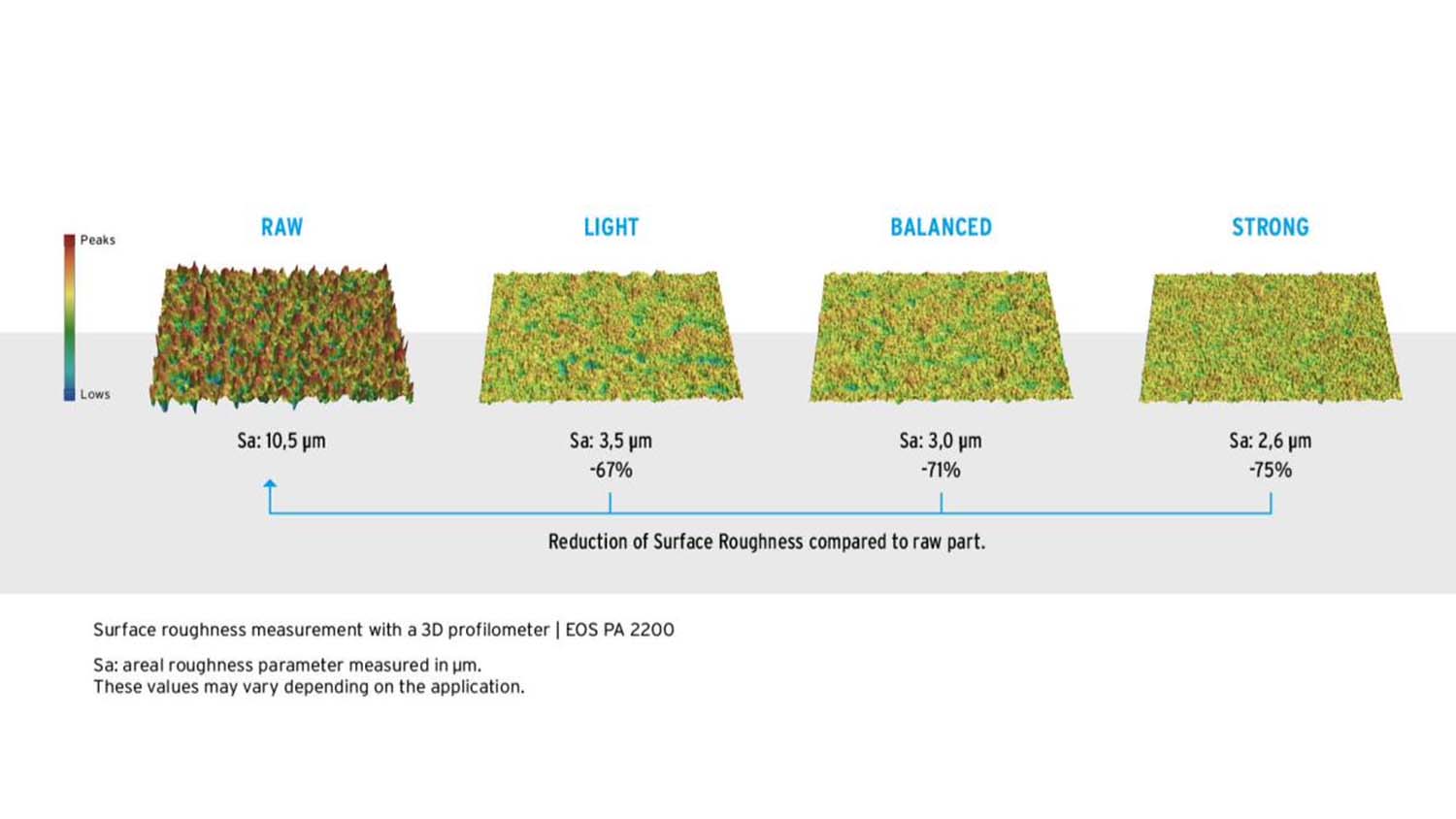

Three ready-to-use parameter sets for different levels of smoothing strengths are available for Powerfuse S users. Named Light, Balanced and Strong, the preset process parameters can also be adapted individually for each requirement of different applications

At present the Levels of Smoothing are available for various materials such as EOS PA 2200, EOS TPU 1301, HP 3D HR PA 11/12 and HP BASF Ultrasint TPU 01, with more materials will follow.

Additionally, DyeMansion is currently validating a new vapour polish method for Polypropylene (PP) parts with the development of an eco-friendly solvent that is biobased and biodegradable.

This PP solution is has already successfully tested for Ricoh PP, HP Ultrasint PP, ALM PP400, VoxeljetPP, AM Polymers PP03, Ultimaker PP (FDM printed), EOS PP1101 and DSM ARNILENE AM6002.

Interestingly, the existing DyeMansion VaporFuse VF47 Eco Fluid solvent process has been passed as compliant with the USA FDA’s food contact regulations, which unlocks a new field of real-world food and beverage applications for which the base polymer is both technically suited and authorised.

As part of its partnership with Stratasys in North America, Stratasys Direct Manufacturing is currently expanding its post-processing capabilities at its Powder Bed Fusion production site in Belton, Texas, adding several new DyeMansion equipment capabilities including the Powershot S and DM60.

“We produce thousands of powder bed fusion parts per month, and our current DyeMansion equipment has become invaluable to processing components efficiently,” said Stratasys Direct VP operations Greg Reynolds.

“Adding more DyeMansion capabilities to further enhance our capabilities was an easy decision. We look forward to introducing these improved finishes to our customers.”