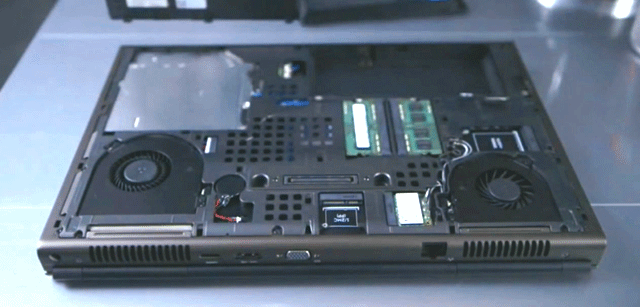

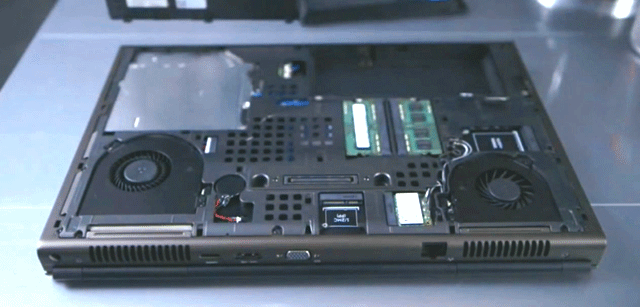

To keep it running cool and to minimise the throttling of its processors, the Dell Precision M4800 features custom thermal solutions, heat pipes and fins, including dedicated fans for both GPU and CPU

Developing a new workstation at Dell takes a huge co-ordinated effort.

Its Precision team spans ten global design centres, with over 250 engineers and architects devoted entirely to the development of workstation-class desktops, laptops and racks.

The company invests over $50M in engineering, which includes the creation of functional prototypes, testing and validation.

In recent years Dell has upped its game in terms of both industrial design and engineering — the Precision T7610 and Precision M3800 are testament to this, both practical and stylish.

But what might not be so obvious is the amount of work that goes into the heart of each workstation — specifically the systems engineering (mechanical, electrical, BIOS, software, thermal and acoustics). It is this that helps set Dell’s workstations apart from its standard desktops and laptops, both in terms performance and reliability.

On the surface, the role of Dell’s Precision systems engineering team is to take off the shelf components and bring them all together in a machine

But this is only a small part of the story. There’s a whole load of optimisations that go on under the hood, covering mechanical, electrical, firmware and software. This is essential — not only to squeeze out those last drops of performance, but to do so in a way that it is reliable, even under extremely heavy workloads.

“Multiple pieces all have to come together in the system,” explains Alex Shows, senior performance engineer.

“Yes they are all industry standard on their own, but when you start to layer them into each other you start finding problems. How is your system designed? Do they communicate right?

“You’ve got a lot of components like the CPUs, the GPUs, memory, chipsets, storage controllers, on and on. They are all on very high-speed buses. There’s not a lot of room for error,” he adds.

Signal integrity

Inside Dell’s Precision lab in Round Rock, Texas, new Precision products undergo a huge amount of testing and optimisation throughout their development.

A major part of this work is to ensure both performance and efficiency of the various high-speed buses including SATA, SAS, memory and PCI Express.

Using state of the art equipment worth a cool half a million dollars, Dell’s Precision labs team goes to town when tuning the high-speed signals in these buses.

“We see over time how the signal shape may vary and if it stays within spec and tolerance,” explains Terry Matula, hardware development engineer. “The scope [oscilloscope] is able to make a bunch of measurements about this. We can see how much noise is in the system, voltage at the right level, timing at the right level, and so on.”

Errors might not necessarily cause crashes, but can have a significant impact on performance. For example, PCI Express Gen 3, the high-speed bus most commonly used for GPUs, is fault tolerant, so if there is an error on the bus, it will just retry until it goes through cleanly. In extreme cases it could even drop down from PCI Gen 3 speeds to Gen 2 speeds.

“If you get a lot of that, it starts hurting performance and if it re-tries all the time then you’re not getting the throughput,” explains Terry.

“If you just did a functional test, it’s possible that it might function OK, but you wouldn’t know that 1 or 2 or 5% of the time you’re actually getting retries,” he adds.

Dell says this is particularly noticeable in benchmarks like SPECviewperf 12, where the datasets for energy and medical are huge — 3GB and up. Workflows where the GPU is used for compute — FEA, CFD or ray trace rendering — are also likely to be impacted.

“In SPECviewperf 11, a re-try every now and again might not hurt you too much, but when you’re talking about transmitting that much data across the bus [with SPECviewperf 12] if you’ve got some percentage of re-tries that have to occur or other things due to signal integrity that might reduce your performance, that’s where you start to see it,” explains Alex.

As part of the testing process Dell varies the characteristics of the waveforms, changing the timing and voltage levels and documenting the results.

“We see how far we can go before we induce a functional failure,” says Terry. “How much noise it can tolerate and still work. All the different memory sizes and configs that we ship; all the different processors. A huge matrix of what we do.

“A lot of work goes into gathering the information and based on what we see we can make design changes,” he adds. “It’s a solid way of making our system more robust and more reliable.”

Adjustments are commonly applied with firmware updates, but in some cases Dell works directly with the component manufacturers to solve issues.

“We design an extra margin so we can have additional confidence in product life and warranties,” adds Bill Guerra, director of graphics engineering.

The Precision M3800 features a stunning 15.6-inch 3,200 x 1,880 touchscreen display

Thermal optimisation

Dell puts a lot of effort into making its workstations run cool so fan noise is minimised and reliability improved.

Its engineering team relies on advanced thermal simulation to optimise airflow within its machines, as Bill explains. “[We do] simulation way early on, looking at how thermals are going to work, almost in turn figuring out how the whole box is going plug in together and work together before we even build the first one.

“So when we do build the first one we can look for variance and make changes as we’re moving forward.”

In the last few years Dell has upped its game in this space, a prime example being the introduction of thermal shrouds in its high-end Precision desktops that force air to flow directly over the memory.

A big emphasis is also placed on the efficient delivery of power. It’s not just a case of plugging in a power supply and away you go, explains Bill. “Our whole evaluation takes into account what thermals it [the power supply] is creating and dumping into the system, and can we get more efficiency out of it that’s cost effective.”

But, arguably, it’s in mobile workstations that optimisations for cooling and power delivery have the greatest impact. Here, inefficiencies not only negatively affect the acoustics of the machine but performance can also take a hit if internal components automatically slow down in order to stay within a prescribed thermal envelope.

Dell claims that in some applications — extreme cases, we imagine — its Precision M4800 mobile workstation can deliver performance that’s up to 18% higher on the CPU and 11% higher on the GPU, compared to its nearest competitor.

“We get this higher performance through higher sustained frequencies over longer durations because we have more efficient power and more efficient cooling in the design because we’re not throttling as much,” he says.

In addition to performance and noise, the thermals inside a mobile workstation need to be designed for user comfort. Dell calls this ‘skin temp’, which it keeps in check with custom thermal solutions, heat pipes and fins — and, in the case of the M3800 advanced materials (see box out).

“When the thing’s sitting in your lap and you’re rendering, does it sear your thighs or is it comfortable,” says Bill. “All of these things need to be balanced together in the solution we design.

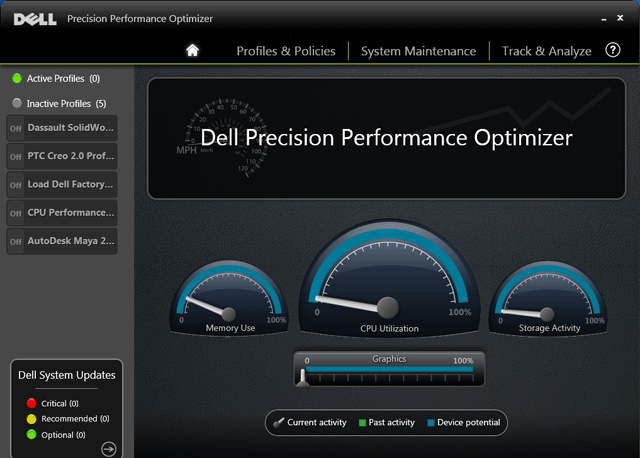

The Dell Precision Performance Optimizer (DPPO), can boost performance in individual applications by automatically adjusting system settings such as hyperthreading and switching on/off CPU cores

Performance tuning

Last year Dell launched the Dell Precision Performance Optimizer (DPPO), a software tool designed to simplify, automate and optimise workstation settings.

The software, which ships with all new Dell Precision workstations, can be used to monitor memory, CPU, storage and GPU usage. It also helps users manage software, driver and firmware updates.

The key focus of DPPO, however, is on application performance, with the software able to optimise the workstation for individual CAD software. This is done through application profiles, which fine-tune operating system, driver and BIOS settings to get the most out of a wide range of 3D tools. These include SolidWorks, PTC Creo, Siemens NX, Catia, AutoCAD and Maya.

To create the profiles Dell’s Precision lab starts off with factory settings, then uses industry standard benchmarks, such those from SPECapc, to optimise the system.

“We look at a variety of application workloads and then we go through and do a large design of experiments, where we change lots of variables, and we look at things like number or cores, disabling hyperthreading, enabling it,” says Alex.

“Things like turbo residency. How can I stay at the highest peak frequency for a longer period of time? Maybe that requires you to go from 12 to 4 cores,” he adds. “We’ve looked at computational workloads. Maybe you need more L3 [cache], so I’ll disable hyperthreading and double my L3.”

Dell adjusts a parameter, benchmarks the system, adjusts another parameter, re-benchmarks, and so on. This results in a complex performance matrix for each individual application.

“What does SolidWorks do with four cores instead of eight?” says Trey Morton, workstation systems engineer. “What does AutoCAD do with a high-performance power scheme?”

“We take the best set of those configurations and those become the profiles within DPPO,” he adds.

Dell acknowledges that modern product development workflows often involve a number of applications so DPPO has logic built-in to run multiple profiles concurrently.

“It will know if the profiles have a conflict – one application wants hyperthreading and one doesn’t,” explains Trey. “And if you activate them at the same time, and DPPO detects that, DPPO will present to the user that there’s a conflict.” It will then ask the user to make a decision.

One of the most interesting behaviours Dell has identified in the development of DPPO is the impact on 3D performance of switchable graphics in its mobile workstations. This is where the machine switches between on-board Intel graphics and discrete graphics (Nvidia Quadro or AMD FirePro), depending on the applications in use.

“Switchable graphics is really important for battery life but, if you want the most performance, with some applications it’s better to disable it,” says Alex.

“With a [Precision] M6800 with [Quadro] K5100M, if you are a Showcase user, you would want to leave switchable graphics enabled, but if you were using SolidWorks or Maya you would want to disable it,” explains Alex. “And by disabling it you would get about 5% greater performance in frame rate.”

“It has to do with the initialisation of the BIOS when it comes up and how the resources are allocated in one scenario versus the next.”

Conclusion

It’s not often you get to see inside the development lab of a major workstation manufacturer – and Dell is certainly one of the largest.

We’ve all heard the marketing mantras about how workstations deliver ‘performance and reliability’ but it’s only when you see first hand what goes into developing a Dell Precision workstation that you really understand what this means. And, in the scope of this article, we have only really scratched the surface of what really goes on behind closed doors.

Of course, it would be naive to think that Dell is the only Tier One workstation vendor to place such a big emphasis on systems engineering. Yet hopefully this look into the world of workstation optimisation should help understand exactly why workstation-class desktops and laptops command the premium that they do.

Materials R&D for the word’s thinnest mobile workstation

CAD journalist, Ralph Grabowski, inspects the M3800’s soft touch silicon overmoulded panel

At DEVELOP3D, we’re big fans of the ultra slim mobile workstation, the Dell Precision M3800. It is a beautiful machine that combines power, portability and a 15.6-inch quad HD display – all in a chassis that weighs less than 2kg.

But one might not realise the amount of materials technology R&D that went into making this lightweight workstation-class laptop a reality.

The research was headed up by Dell’s global CMF team (colours, materials, finishes), which not only experiments with new materials and ideas, but drills down into the manufacturing process, creating prototype tooling, establishing supply chains and implementing everything into the new products.

Material choice

Few would disagree that Apple revolutionised the laptop with its unibody MacBook chassis, which is machined from a single piece of aluminium.

Dell arguably drew inspiration from this premium product when designing the Precision M3800. But instead of using aluminium throughout, it applied different materials and manufacturing techniques to three key components: the display cover, the mid panel and the base.

The display panel

In addition to being light and thin, one of the key requirements of the display cover was to protect the quad HD panel. For this Dell developed a new manufacturing process which CNC machines forged aluminium, a material that exhibits greater strength than standard aluminium.

“To help us get the rigidity we wanted, and also some of the costs savings and benefits, we’d start by forging the metal, getting it to the basic shape, and then we’d come back and CNC that,” said Paul Doczy, Dell industrial design director. “The end result is an incredibly sturdy, solid part that is not only lightweight, but beautiful.”

The mid panel

For the panel that surrounds the keyboard and trackpad Dell used magnesium, which is also exceptionally strong and lightweight. But, as is common with workstation-class laptops, the Precision M3800 creates a fair amount of heat, so Dell needed to find a way to ensure the palm rest surface didn’t get too hot.

“Doing experiments in house we found that silicone had great properties but the issue was how do you get silicone overmoulded onto the magnesium and maintain a very thin design,” said Doczy.

“So through this process of silicone overmould we take the magnesium – in its raw state, it’s not very pretty – and then we chop up silicone, we heat that in a press and we get it down to 1/2mm thick.

“That 1/2mm creates a protective bond with the magnesium that is not only very comfortable and easy to use, but keeps it cool to the touch.”

Dell’s unique silicone overmoulding process doesn’t end there. To keep fingerprints to a minimum, a special overcoat is sprayed on top of the silicone.

“You’ve seen black soft touch products before that, after a while they start to get a little nasty looking,” explains Doczy. “If you play with the silicone on this [Dell Precision M3800] you’ll notice it really resists fingerprints quite well.”

The base

The base of the laptop threw up similar challenges in terms of how to keep the design lightweight and strong while shielding the user’s lap from heat.

Dell achieved this by using carbon fibre, which, in addition to being incredibly strong, is also a natural insulator.

“The engineers are able to maintain the highest level of performance in this box and not worry about skin temps [on the lap], because the material itself helps spread that load,” explains Doczy.

The bottom of the laptop is finished off with a clear soft touch material, so the carbon fibre weave is clearly visible, making it a focus of the design. It’s an aesthetic that splits opinion, but certainly a bold expression of the advanced materials that go into making the M3800 so light and strong.

“[With the Precision M3800] we’re not just looking for decorative finishes, we’re looking for beautiful materials that bring us functional advantage,” concludes Ken Musgrave, director of design, Dell. “And we can tell any one of our customers exactly why we have picked each material and used it that way.”

The hidden lengths the company goes to when designing its desktop and mobile workstations

Default