Packaging redesigns are serious undertakings. On the marketing side, changes are visual and emotional; on the manufacturing side, they cost money.

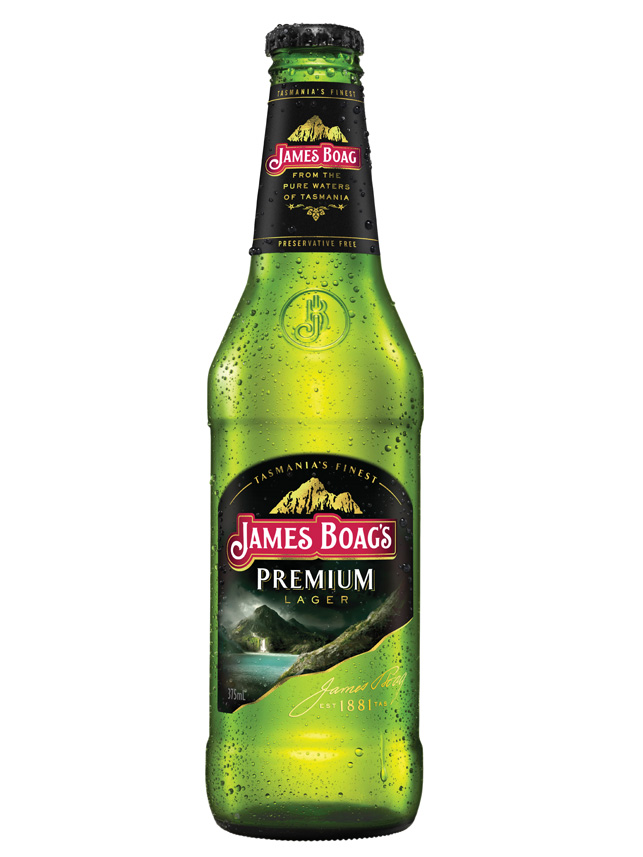

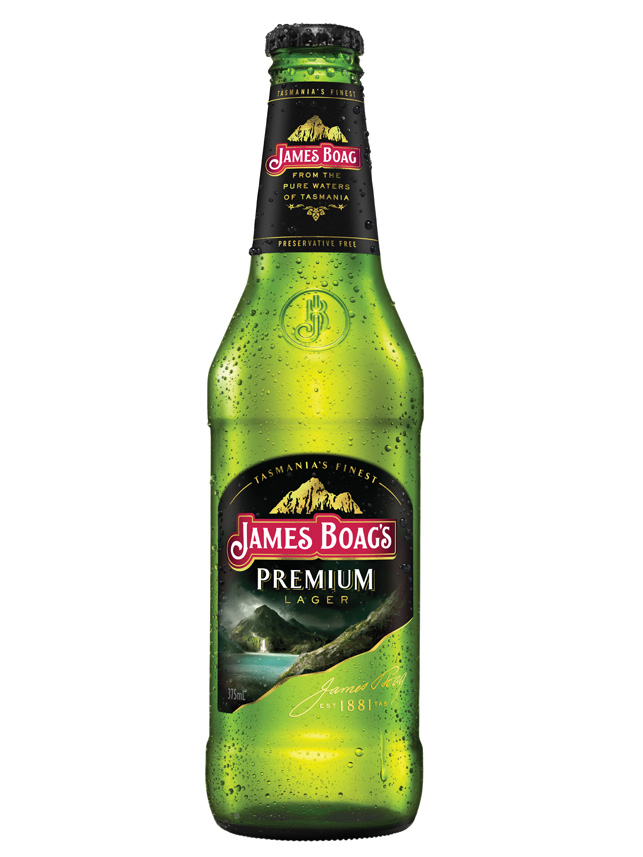

Before making the investment to overhaul its glass bottle tooling systems, the maker of Australia’s James Boag’s Premium Lager needed to be confident that an updated bottle would not just represent change for change’s sake. Instead, the company needed to be sure that the new bottle would look good and be well received by customers. Ideally, it wanted confidence on these issues before spending significant time and capital on the project.

As the supplier of Boag’s bottles, Orora had a vested interest in validating the design quickly and accurately. Orora’s innovation and design team started by contacting long-time partner, 3D Systems’ On-Demand Manufacturing Services, to assist in the development of a state of the art 3D-printed prototype.

With Boag’s existing supply chain processes in mind, a new-look bottle was designed to comply with the manufacturing infrastructure already in place, in order to avoid expensive and timeconsuming changes to that infrastructure.

Orora – 3D printing a glass lookalike

To get Boag’s buy-in on the new design, a credible-appearance model was needed for evaluation.

The 3D-printed models needed to be convincing and have the same clarity and hue as glass, as well as the same in-hand heft. 3D Systems’ Manufacturing experts accounted for weight disparities by adjusting the interior wall thickness of the design file based on the density of the selected stereolithography (SLA) resin, and then got to work on colour-matching to achieve the correct green used in the classic Boag bottle.

Using 3D Systems’ SLA 3D printing technology and VisiJet SL Clear resin, they printed four SLA prototypes.

Once printed, the bottles were put through an in-house finishing protocol to bring them to final product quality. This included wet and dry sanding, applying a surface tint and then a final clear coat to deliver a glass-like sheen. With just a few simple steps, clear SLA prints were transformed with impressive results.

Fast feedback

The appearance models were ready within a week, allowing Orora and Boag to quickly put the new design through customer trials and gauge the public’s reaction.

They filled the 3D-printed bottles with liquid, outfitted them with a label and cap and put them in a shop for monitoring.

Feedback from these in-store trials indicated that the new design was a hit, clearing the new design for production.

“The new James Boag’s Lager bottle has set a standard within Orora for the way packaging design and 3D prototyping can come together seamlessly with short notice,” said a spokesperson for Orora’s innovation and design team. “It’s the sort of technology innovation that’s giving us a critical edge when it comes to developing best-practice bottling design and manufacturing solutions for our customers.”