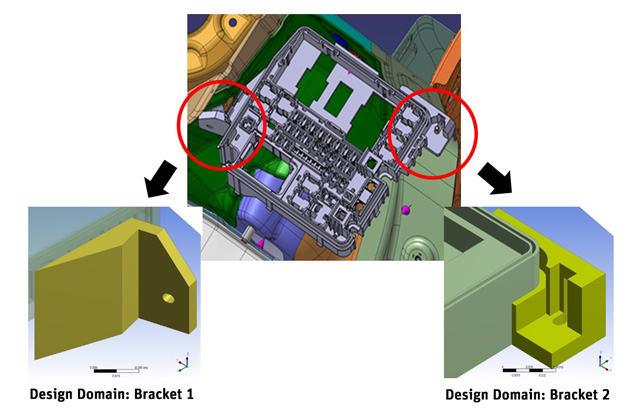

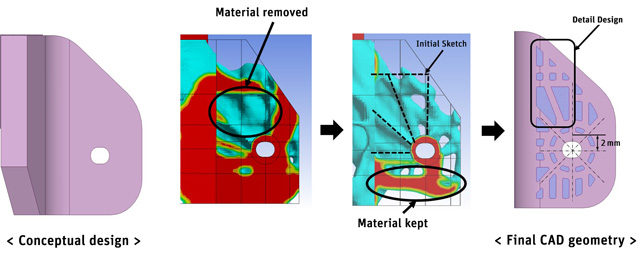

Topology optimisation areas (Image courtesy of Kyungshin, Incheon, Korea)

A smart junction block is the central nervous system of an automobile. The PCB of the junction box manages the electricity and distributes power to all parts of the vehicle, so it is a critical component of the modern car.

Because of the vibration and high temperatures in the engine compartment, the junction block and the bracket that connects it to the chassis must be designed with high stiffness to resist cracking and vibration fatigue.

Traditionally, the bracket was designed using a build-and-test method, which was slow and costly. Also, engineers tended to use more material than was necessary to ensure high stiffness, which raised the cost of raw materials.

To avoid such over-design problems and develop plastic junction block brackets with optimal dimensions to maintain the necessary stiffness, Kyungshin engineers used the topology optimisation functionality of AnsysMechanical to design durable, lightweight brackets.

With topology optimisation, the simulation software automatically determines the best shape once engineers specify where supports and loads are located on a volume of material. For example, instead of a continuous solid bracket, topology optimisation might find that a lightweight design with ribs and void spaces produces a bracket that meets all mechanical requirements. In this case, Ansys Mechanical’s topology optimisation capability performed digital exploration to determine the optimal bracket shape, rib shape and rib positions.

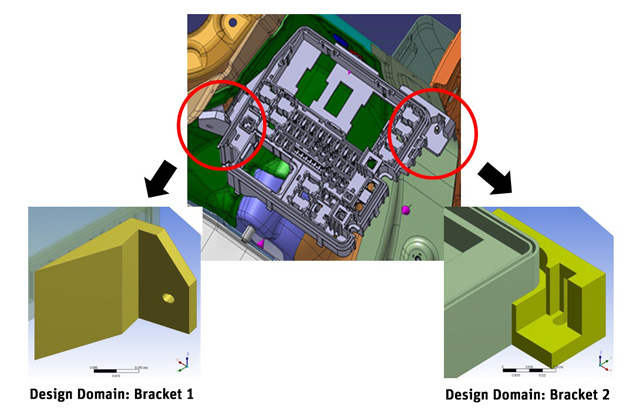

Definition of vibration simulation conditions (Image courtesy of Kyungshin, Incheon, Korea)

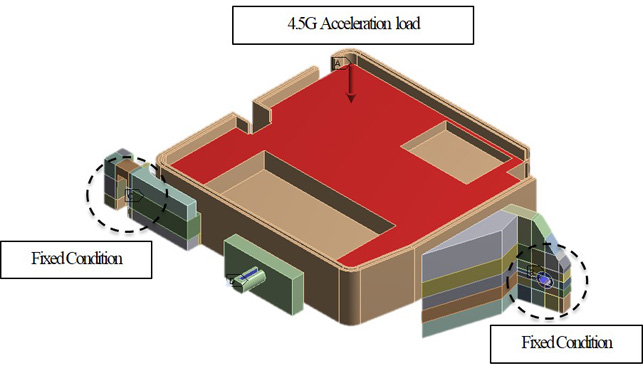

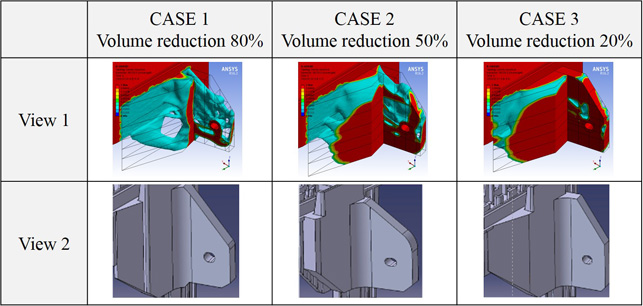

Optimal model of bracket based on optimal design value (Image courtesy of Kyungshin, Incheon, Korea)

Kyungshin – Three steps to success

In the first step of the design process, Kyungshin engineers defined the load conditions experienced by the bracket in normal operation, established the allowable range of design parameters and generated an initial design based on the density distribution of the bracket using topology optimisation.

The bracket size was limited to the available space in the engine compartment that would not interfere with any nearby component. Engineers defined the vibration simulation conditions of the bracket by stipulating fixed points in the design and the acceleration load (4.5G) experienced due to vibration.

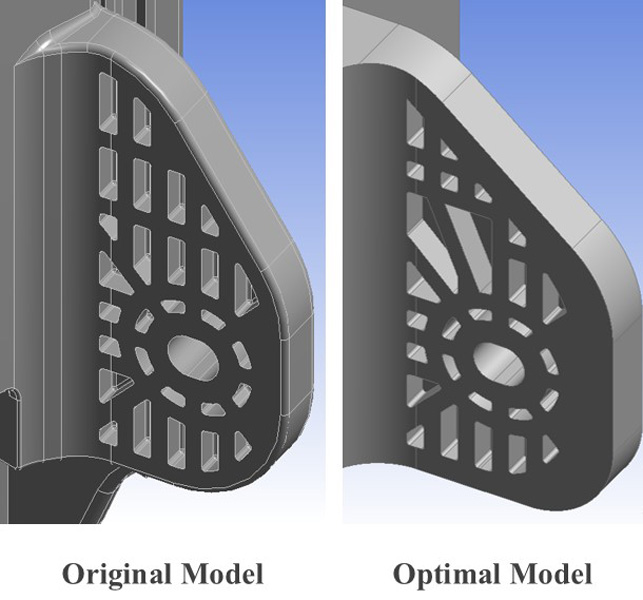

They then used topology optimisation to generate an initial bracket layout using density distribution analysis. They explored brackets with density distributions of 20%, 50% and 80%, and verified a bracket shape in each case that would provide the desired stiffness.

The second step involved shape optimisation of the bracket based on the 50% density distribution model developed in the first step. Kyungshin engineers generated a parametric model with minimum and maximum dimensions for each defined design factor, including right and left side bracket width, height, angle and centre radius.

They then performed design of experiments (DoE) simulations, automatically employing the manual central composite design (CCD) algorithm in Ansys OptiSLang to obtain an optimal value for each parameter that resulted in a bracket with reduced mass and increased stiffness compared to the original bracket they were trying to replace.

Finally, the engineers verified the performance of the proposed optimal bracket using vibration fatigue simulation. The simulation involved varying the vibration acceleration from 4.5G to 3.0G over three minutes while the vibration frequency varied from 20–50Hz (at 4.5G) to 50–200Hz (at 3.0G).

The simulation also cycled the temperature from 90C to –30C back to 90C over a 24-hour period to ensure that the bracket could withstand the temperature variations inside the engine compartment.

Initial layout shape of bracket rib (Image courtesy of Kyungshin, Incheon, Korea)

Result of density distribution for Bracket 1 (Image courtesy of Kyungshin, Incheon, Korea)

A better bracket

The vibration fatigue simulations revealed that the optimal model had a breakage lifetime of 2,259 operating hours versus 1,544 hours for the original bracket model.

This is an increase in product lifetime of 46% – a significant improvement.

The new bracket also was lighter, using 16% less plastic than the original, continuous solid bracket. In the process, Kyungshin engineers reduced the development period for the new bracket from six months to three months, greatly decreasing development costs.

They also created a new thermal-vibration-fatigue simulation process using Ansys Mechanical running on Ansys Workbench, in order to forecast the breakdown of the junction block bracket, which can be used in preventive maintenance scheduling.

By substituting simulation for traditional methods that relied on an engineer’s experience and existing design standards, Kyungshin engineers have cut in half the number of bracket performance verification analyses, from eight to four.

At a cost of approximately 50 million to 100 million South Korean won (US$45,000 to $90,000) per verification analysis, this is clearly a major saving.

In addition, they have produced a reusable model on which to base all future junction block bracket designs.

The new model, employing Ansys topology optimisation, offers a flexible design scheme, which the engineers at Kyungshin will be able to modify for any other component that they may decide to manufacture in the future.

Topology optimisation ensures cost savings through designs that use the minimum amount of material necessary to meet required mechanical standards while increasing product lifetime.