Credit: Jules2000/Shutterstock.com

In many engineering applications, surface treatments and coatings are a critical step. They offer designers the opportunity to reduce corrosion, improve durability, experiment with thermal and mechanical properties – and that’s without mentioning the aesthetic considerations involved. But for all their advantages, surface treatments and coatings add a new layer of complexity when making design decisions.

In particular, there may be risks to weight up around restricted substances, because chemicals harmful to the environment or to human health may be introduced to a product, either as ingredients of a coating or paint, or as a result of how it is applied.

So how can organisations easily and accurately identify the restricted substances risks in their products that result from a surface treatment?

This is fundamentally an information challenge, and more specifically, a materials information challenge. The amount of information involved is large – very large, in some cases. And the interconnections between data are complex to manage and navigate.

Nevertheless, it is important to understand how surface treatments are connected to material decisions and take steps to mitigate any risks.

You might, for example, start with a database, in which data on all possible surface treatments is linked to data on all possible related materials – but then you need also to link all materials to all possible related substances; all substances to all regulations that control their use; and connect specifications to the materials and surface treatments that might be used to fulfill them.

On top of that, the data itself needs to be paired with understanding and, in an ideal scenario, rather than simply report on products after they have been made, we want to connect that knowledge to engineering and design decisions – and do so as early in the chain of decisions as possible.

Getting the full picture

Currently, the process of identifying at-risk substances often involves either wading through existing supplier information, or requesting that suppliers make declarations about their materials and coatings. Not only is this very time-consuming, but data is often incomplete as suppliers will, understandably, want to maintain competitive advantage by revealing only the bare minimum information.

And of course, this is assuming you can get a supplier response within the timeframe that it is needed. Either way, this process will likely impact time-to-market, cost and efficiency, and you may still be left with an incomplete picture, with gaps in company knowledge, which in turn result in risk. A designer applying a specification for rustresistance, for example, may not know the full restricted substances consequences of that spec.

The aim, then, must be to fill these gaps in company knowledge and to connect related information efficiently, in order to support fast compliance queries – and, if possible, to do so as early in the design and development process as possible. But how?

Granta MI – Mitigating restricted substance risk

The Environmental Materials Information Technology (EMIT) Consortium is a collaborative initiative that involves Airbus Helicopters, Boeing, Honeywell, NASA and Rolls-Royce, as well as materials information software company Granta Design, among others. Its aim is to enable product design and development in the context of environmental objectives and regulations.

Together, these companies are focused on the development of software and systems that support business risk reduction, cost reduction and legislative compliance through product stewardship best practice.

The consortium also aims to develop the necessary materials datasets to support those software and systems, and ensure they can be embedded into existing product development and innovation activities. This means they can be effectively used by engineers, design teams and managers across an organisation. EMIT members combine their expertise and resources to share the costs, effort and benefits of developing environmental materials information technology.

Take, for example, aerospace giant and consortium member Boeing; aware of accelerating regulatory requirements, it was looking for a way to connect information on materials, specifications, regulations and parts, but with historical data going back decades, it realised that this would involve tracking and reporting on vast amounts of information.

In order to link these information types – and to help overcome gaps in vendor information – Boeing deployed Granta MI as its centralised hub of materials knowledge for its restricted materials project. This enabled it to integrate restricted substance information along with other materials data.

Those involved with the project at Boeing claim that the return on investment has been significant, particularly in areas such as data clean-up, risk mitigation and efficiency. That proved important when Boeing faces questions about its use of mercury in Canada.

During EMIT’s first five-year phase, in which it has helped in the development of Granta MI, the system’s capabilities have been extended to help it better capture all data on materials, processes, substances, specifications, surface treatments and related ecological data.

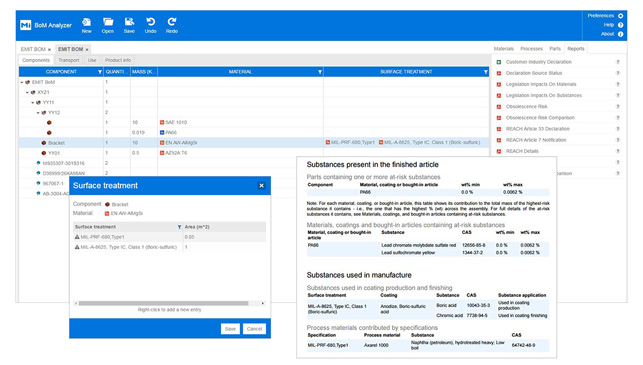

Analysing substance risk for a product, including surface treatment specifications, through GRANTA MI

Granta MI – Informed choices

Informed choices require data structures and tools to map out and query the connections between all the components in a treated material. But this doesn’t entirely fill the gaps in what you need to know. It’s also important to enrich proprietary data from validated reference data sources.

Granta MI, for example, goes beyond being an ‘empty data container’, because it includes data on materials, coatings, substances and regulations. The resulting comprehensive data resource can be queried to answer questions such as, ‘Which at-risk substances might be associated with this coating?’, and can include information from within CAD design tools, for example.

Sometimes, this data is sufficient to answer key design questions, saving you the effort of getting data from suppliers. On other occasions, it helps you to identify where the highest risks lie, so you can prioritise your data collection efforts accordingly.

The most recent development has been to enhance this reference information with improved data on surface treatment specifications, obtained via a link to Surface Treatment Specifications from SAE stored within the IHS Engineering Workbench (EWB) system. This development results from a partnership between Granta, IHS and SAE.

Getting quick answers is particularly important if you want to embed compliance considerations into design. For organisations such as Rolls-Royce, which makes products with extremely long lifecycles, the ability to take a proactive rather than a reactive approach during design means that problems can be identified early on, and restricted substance risk can be reduced. As highlighted by Rolls-Royce at an open seminar hosted by the UK’s National Physical Laboratory (NPL), which helps to administer the EMIT Consortium, “environmental performance by design” leads to greater revenue than “reactive design”.

Ultimately, the message is clear: Any company that cares about restricted substance risk will see measurable benefits from having a centralised hub of materials knowledge that can capture all corporate data on materials, processes, substances, specifications, surface treatments and related eco data; that can provide access to validated, trustworthy reference data; and that ensures critical information is available to those who need it, when they need it, throughout the design and development process.

Spotting the hazards in coatings and treatments

Default