We are in the middle of a fantastic revolution in product design. Never before has it been so easy for an idea to be taken from sketch to reality. Through software, products can be refined and improved, before ever being fabricated. 3D printing has gone through the ‘hype-cycle’ and now the range of materials has grown from flimsy plastics to metals with many new tools to optimise topology.

Funding and traditional start-up pain points such as crowd sourcing, part fabrication and sourcing have equally benefitted from the revolutionary forces of the internet with everything now just a Google search away.

Product design is also breaking free of the chains which impaired mixing and matching tools. It’s easier than ever to define your own process and pick the best tools to complete the right phase of the product design process.

Ownership is changing, with subscription and historical perpetual licences altering the cost of ownership paradigm.

The cloud is also bringing incredible power to the desktop to utilise Artificial Intelligence (AI) to aid design, through simulation and accelerate iterative design, ensuring compliance with forces, loads and defined conditions.

In many ways, the tools we have been using for the last two decades were created for a non-digital fabrication process, a pre-3D printed world.

With new ways to fabricate and new ways to fundamentally understand a design’s performance, software tools are changing from aiding model definition to actually assisting in the optimisation of a design for quality and fabrication, optimising strength, material usage, geometry, and even aesthetics.

As the games industry continues to drive graphics performance and lower the cost of GPUs, design software and workstation performance have benefitted greatly.

This has expanded into emerging Virtual Reality (VR) and Augmented Reality (AR), as hardware developers create headsets for gamers, at relatively low consumer price points. This, in turn, benefits designers too.

While most VR and AR is still about creating experiences, software firms are making early steps into applying these headsets in design and manufacturing environments to aid product definition, fabrication and servicing.

Location

The DEVELOP3D editorial team are hard at work putting the final details together for our second USA conference, which will take place in the George Sherman Union building of Boston University in the afternoon of 23 October and all day on 24 October.

Given the success of last year’s event at District Hall in downtown Boston, this year we have upgraded the venues to allow for more exhibitors. An additional room also means that more delegates can attend the multiple tracks during the day, allowing us to dig deeper into 3D printing, VR/AR and digital fabrication.

With Boston University’s esteemed Engineering department and the Engineering Product Innovation Center (EPIC), we feel we have found a great USA equivalent to our ongoing partnership with Warwick University in the UK and the Warwick Manufacturing Group (WMG).

As with the university tours offered at DEVELOP3D LIVE in the UK, there will similarly be escorted visits to the nearby EPIC building. The expert facility contains a host of digital fabrication technologies and is a local source for product innovation, design, prototyping, manufacturing and life-cycle management expertise.

Agenda

On Monday 23 October, the event will kick off at 3pm. Following the last talk, delegates and exhibitors are invited to a reception on in the George Sherman building. There will be plenty of time to socialise and get hands on with the fantastic array of exhibits on the show floor.

On Tuesday 24 October, proceedings will commence at 9am with a joint session with the keynote speakers.

Following the coffee break, delegates can choose to attend one of two simultaneous tracks for the rest of the day. These will feature industry speakers on digital fabrication, 3D printing, AR/VR, simulation, CAD tools and many other topic areas.

Our speakers are industry experts, leaders of software and hardware development and exemplary customers that are pushing the envelope of the design/ fabrication process. Keep checking back to our website – d3dliveusa.com – as we will be adding these over the coming weeks.

Exhibiton

With over 30 exhibits, there will be plenty of technology on demonstration, covering all aspects of design and fabrication. We have a dedicated VR/AR spaces for immersive and hands-on engineering experiences.

With so many industry experts coming to DEVELOP3D LIVE it will be a great space to come and get advice or find a solution to a design, process or manufacturing process.

Conclusion

Our second iteration of DEVELOP3D LIVE Boston gives us the opportunity to provide an experience much closer to our successful long-running event in Warwick with more multiple tracks, more exhibitors and more chances to get hands-on with the technology.

To get an idea of the kind speakers we have, check out the videos from our previous UK and US events where you will find over 100 past talks, covering many fascinating topic areas. Talks from the likes of Porsche, JCB, Jaguar Land Rover, Microsoft, Autodesk, Bose, SolidWorks, IKEA, Siemens, Stratasys, PTC and much more.

To join us for DEVELOP3D LIVE USA, get your discounted tickets ($30 for a very limited time) by visiting: d3dliveusa.com/buy-tickets

DEVELOP3D LIVE USA conference

Alongside the exhibition and demonstration areas, a key feature of DEVELOP3D LIVE is the conference tracks.

For this year’s event, we’ll be focussing on three streams of talks:

Main stage & keynotes

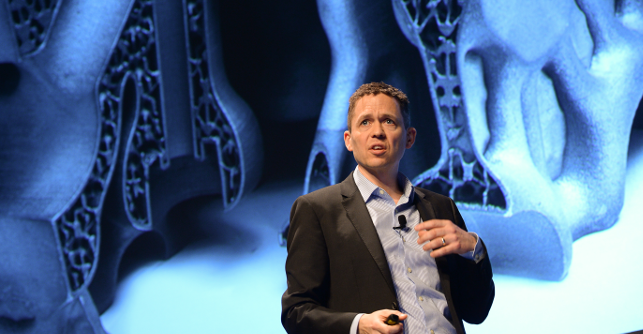

Our main-stage will feature keynote user stories as well as industry updates from key software company executives.

We’ll focus on providing both updates from the key vendors in the product development technology world as well as a glimpse into some interesting start-ups.

Our goal is also to provide you with inspiration, to enable learning from your peers about how they bring their own products to market and to provide inspiration to take back to your team as well as to arm you with a vision of the future (both near and further out) to help plan your product development technology related decisions.

Additive & 3D printing

Additive manufacturing and 3D printing has become the hot subject in the last couple of years.

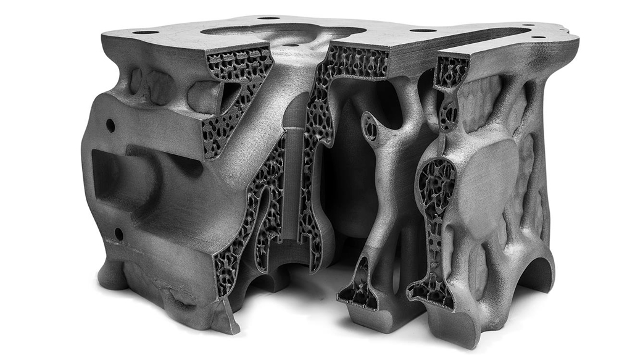

With lower cost machines combined with more advanced techniques than ever before, now is a good time to see how it can fit into your workflow, how you might gain competitive advantage through adoption. Our additive manufacturing track will cover the spectrum of technologies available.

From using low-cost machines to benefit prototyping (both in design and production) to the advanced state of the art metals machines.

We’ll also explore the interaction of optimised structures and additive production to break new ground.

VR, AR & visualisation

With the rise of more affordable and capable head mounted displays, virtual reality and augmented reality is back with a bang.

Alongside advanced visualisation techniques, there has never been a better time to explore your design and engineering projects in an immersive and realistic way.

We’ll learn from leaders in the field, both from technology perspective as well as those implementing it, to find out how it’ll fit into our daily workflows and bring a new age of realism and interactivity to the fore.

A look at what’s in store for this year’s event in Boston USA

Default