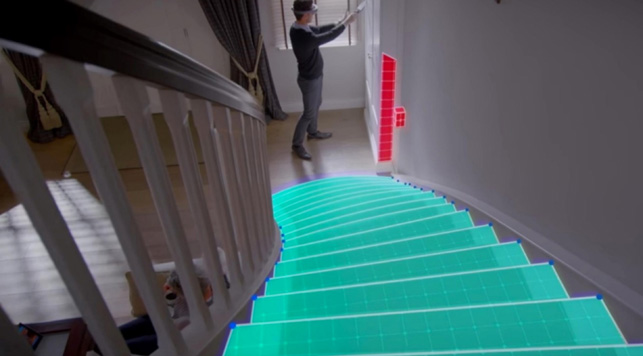

thyssenkrupp is using the Hololens to help slash the time it takes to measure up, design, visualise, quote and manufacture its custom stair lifts

Fujitsu Forum covers the whole gamut of enterprise IT, from artificial Intelligence (AI) and the Internet of Things (IoT) to big data and security. With 10,000+ delegates hungry for information (and pretzels, beer and curry wurst, of course), technology for product development and manufacturing doesn’t always get the stage time we think it deserves.

One of the stand-out sessions this year was dedicated to Virtual, Augmented and Mixed Reality (VR/AR/MR) and featured speakers from Fujitsu, Nvidia, Microsoft and Autodesk.

Microsoft’s Michael Zawrel shared a compelling case study on MR using the HoloLens. German multinational thyssenkrupp is using the MR device to help design and manufacture its stair lifts, which are custom-designed for every household.

Traditionally, a sales rep would measure each and every stair by hand, then go back to the office and enter the information into an ERP system. Some time later the customer would be sent a quote for production and installation.

thyssenkrupp has dramatically accelerated the process with the help of the HoloLens. First, the device’s built-in sensors are used to measure the entire stairway in a matter of minutes. Soon after, the customer can be shown a holographic version of the custom stair lift design in the context of their own stairway. The measurement data is also sent from the HoloLens to an Azure cloud service so the customer can get a quote the same day – broken down by materials, production and instalment. Then, as soon as a sale is made, the job can be automatically sent to production.

With the help of the HoloLens, thyssenkrupp has found its process is now up to four times faster than before – from first call to final installation. “No one can deliver stair lifts faster than thyssenkrupp,” said Zawrel. It gives them a competitive advantage.

Nvidia’s Andy Hendry focused on the needs that designers have for VR. This includes accuracy – both visually, for aesthetic evaluation and dimensionally, for form and fit – as well being able to work collaboratively across different geographic locations.

“Designers want to be able to interact with their design, to touch it, to mark it up,” he said. “They want to be able to check measurements and they want to be able to make changes.

“They need to be able to open and close things like a car door or see each component on its own and how each component comes together with other components.”

Hendry was in fact describing the capabilities of a project called Nvidia Holodeck, a collaborative VR environment for designers and engineers that Nvidia is billing as the design lab of the future. In Holodeck collaborators are represented by humanoid avatars and interact with the virtual world through gestures and speech. AI can also be used to suggest options based on related designs. The following video is well worth a view to see where VR is potentially heading.

Holodeck is still in its infancy and Nvidia is inviting designers with powerful VR Ready computers and 3ds Max or Maya skills to apply for early access to the technology.

Swapping future vision for current reality was Autodesk’s Danny Tierney. The automotive and industrial design specialist has helped set up the Autodesk VR Centre of Excellence in Munich Germany.

The customer-focussed facility primarily delivers a professional environment for showcasing current VR/AR and MR technologies, but it also acts as catalyst for R&D. Since the centre opened in February 2017, it has attracted over 500 visitors from around the world, some VR/AR/MR novices and some who are already pushing the boundaries and helping influence future developments.

There’s some fantastic technology at the centre, including collaborative design review based around Autodesk VRED Professional and the HTC Vive, with participants both on and off site. Moving beyond a purely virtual experience, there is also extensive merging of the real and virtual worlds using cameras and green screen technology.

Tierney made the important point that VR is not just a headset and the centre also features a 3D passive stereo 4K powerwall, which mimics a CAVE (computer aided virtual environments) where a user’s perspective is tracked using an advanced real-time system.

He explained how VR is highly scalable and while a four-, five- or six-sided rear projection CAVE might suit an automotive multi-national with deep pockets, entry-level systems are within reach of firms of all sizes.

The Autodesk VR Centre or Excellence is powered by several Fujitsu Celsius workstations with one or two high-end Quadro GPUs. Fujitsu’s Thomas Bretthauer introduced the company’s growing family of ‘VR Ready’ workstations, which now includes three desktop machines – the Celsius W570, Celsius M770 and Celsius R970 – plus the 17-inch mobile workstation, the Celsius H970.

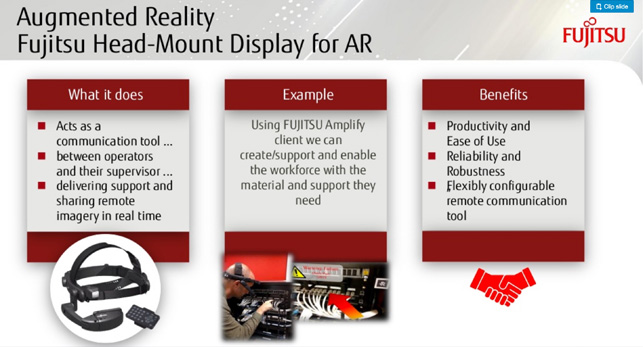

Bretthauer also gave some stage time to Fujitsu’s Augmented Reality head mount display which can be deployed in the field for maintenance tasks or on a factory assembly line.

The AR headset can be used to view images or video pertaining to the task at hand, while leaving both hands free to perform it. It can be controlled with a wearable keyboard or by voice input to carry out a variety of operations, including turning pages in a work manual, entering numbers or taking images with the built-in camera.

The device can also act as a communication tool between the operator and the supervisor, where the supervisor can see what the operator is looking at and then overlay appropriate documentation or imagery to help with the task.

Fujitsu’s AR technology is being deployed in the field for maintenance tasks or on factory assembly lines, giving workers access to critical information hands-free.

Workstation innovation

For a company that prides itself on designing, engineering and manufacturing all of its workstations in Germany, it’s surprising that Fujitsu has only truly started to innovate in the last few years.

The Celsius J550 was the first Small Form Factor (SFF) workstation from a major OEM that could take a full height graphics card, offering more 3D performance for demanding CAD users. Meanwhile, the space saving ‘VR Ready’ Celsius W570power+, which was launched earlier this year, is around 30% smaller than the competition.

Now, the company has turned its attentions to serviceability, an area that it has traditionally lagged behind.

This is embodied in the new Celsius M770, a single CPU workstation for CAD/CAE, design viz and VR that features a completely redesigned chassis. Key components, from storage to power supply, can be removed in seconds without a tool, using green touch points and cold plug technology to help minimise downtime in case of a fault.

Not surprisingly, the M770 took centre stage at the Forum, where it appeared in both physical form on the show floor, and in virtual form in a fully interactive VR experience.

The machine features a choice of new workstation-class Intel Xeon W Series CPUs, Nvidia Quadro Pascal or AMD Radeon Pro GPUs, up to 256GB ECC, 2,666 MHz memory and a huge range of storage from SATA HDDs to NVMe SSDs

Serviceability starts with storage, with up to four drives easily accessible from the front of the machine. Green touch points are used to open a bottom panel, then the drives can be removed by pulling out the caddies. The drives automatically mate with a custom back plane inside so there are no cables to connect to data and power. The system comes set up for 3.5-inch or 2.5-inch drives, but the back plane can be changed to accommodate other storage types including U.2 NVMe SSDs.

Plastic shrouds help improve airflow inside the Celsius M770

Serviceability is improved through green touch points

The M770’s side panel can be removed with one hand, revealing a new tri-channel design with plastic shrouds, echoing that of the HP Z8 and Lenovo ThinkStation P920. The shroud covers most of the internal components, but Fujitsu has embossed them with symbols – CPU, GPU, fans etc – to make it easier to locate what lies beneath.

The top third of the chassis features a removable air duct that incorporates two low duty fans that sit either side of the CPU to push and pull air over the heatsink.

The middle section is reserved for one or two GPUs, which are held in place by a tool-less mounting bracket. Meanwhile, the bottom section houses the power supply and storage.

The front I/O board is also removable, so the machine can accommodate future I/O technologies. The board can also hold a single M.2 NVMe SSD to complement one or two that a mounted directly onto the motherboard. More M.2s can be added with optional PCIe cards.

Overall, we were very impressed with what we saw of the M770, which now looks to put Fujitsu shoulder to shoulder with the other Tier One workstation manufacturers when it comes to serviceability.

Celsius M770 #workstation. Cold swappable power supply can be replaced in under a minute. #FujitsuForum pic.twitter.com/9QKrlvJBqV

— DEVELOP3D (@develop3d) November 9, 2017

M770 – CPU / memory covered by easily removable air duct, with two low duty fans that sit either side of the CPU. No cables. #FujitsuForum pic.twitter.com/7JjN3paM3V

— DEVELOP3D (@develop3d) November 9, 2017

Step inside the machine

To highlight some of the features of the workstation, customers were also able to experience the new chassis in VR using an HTC Vive headset running on an actual Celsius M770.

With the help of the Autodesk VR Centre of Excellence in Munich, Fujitsu created a realistic VR experience so delegates could literally step inside a five-times larger than life workstation and get a real sense of the ease with which it can be serviced.

Starting with the side panel, individual components can be removed one by one, simply by brushing your avatar hands over the green touch points.

The VR experience was created in Autodesk VRED Professional, with data brought in from PTC Creo, the 3D CAD tool Fujitsu uses to develop all of its mechanical designs.

However, Fujitsu’s 3D engineering models are not geared up for design viz. With low-res proxies for parts like GPUs, fans and hard drives, detail needed to be added in some areas. Once inside Autodesk VRED Professional, lighting and materials were applied for realism, alongside avatars and mechanisms for user interaction.

Virtual Reality is not commonly applied to smaller products – and while the VR experience was primarily done as a marketing exercise (and to help Fujitsu better understand the challenges its customers face when creating VR experiences from engineering data) it also highlighted how VR could be used for virtual service manuals.

Some firms are already using similar VR experiences to help train engineers on how to maintain larger scale products out in the field. This not only means engineers can be trained on products that have not yet been built, but in expansive markets like the US it can significantly cut down on business travel or shipping of heavy products.

Training in VR can also help aid knowledge retention because it uses a different part of the brain. Speaking at AEC Magazine’s NXTBLD event in London earlier this year, Skanska’s Paul Nichols explained how VR is helping the firm’s workers and supply chain remember information for longer. Six months after training had been done using VR they found knowledge retention had increased to 80%, up from 20% using traditional methods.

Following Fujitsu Forum, we also had the pleasure of visiting Autodesk’s VR Centre of Excellence in Munich. We’ll bring you a full report next year on some of the fantastic work they are doing.

Exciting developments in VR/AR/MR plus fast workstations to run them

Default