For the Solar Orbiter, a collaborative ESA/NASA to study the sun and its outer atmosphere, Almatech created this abrasives-free, slit-changing mechanism for the imaging spectrograph

In the Star Trek media franchise, the USS Enterprise’s mission is famously: “To boldly go where no human has gone before.” Manned space voyages on the kind of scale depicted in TV shows and movies may remain the stuff of fiction, but supporting deep- space missions is the day-to-day work of the team at Almatech, a Switzerland-based company that provides critical hardware and engineering services to the space market.

Established in 2009, Almatech is based at the École Polytechnique Fédérale de Lausanne (EPFL) Innovation Park and is frequently involved in the design of components for the spacecraft programmes of the European Space Agency (ESA), among others.

Almatech’s 25 scientists and engineers develop structures and mechanical solutions for spacecraft, naval vessels and general engineering projects. These need to deliver exceptional performance when it comes to accuracy, reliability, lightness and so on, often in the most extraordinary of environmental conditions.

During deep-space missions, typically lasting several years, satellites may be exposed to temperatures ranging from -160°C to more than 350°C; acceleration forces amounting to several G; and high levels of various kinds of radiation. At the same time, there are no gravitational effects such as thermal convection, and this must be taken into account. On-board instruments and associated fixtures require high precision and operational reliability.

“Although they are optimised for minimum weight, their stability and functionality need to be sustained over several years without any maintenance or cleaning,” says Dr Luc Blecha, chief technical officer at Almatech.

Almatech – structural components for outer space

Examples of Almatech projects include its work on the Characterising Exoplanets Satellite (CHEOPS). Scheduled for launch in late 2019, CHEOPS will observe individual bright stars known to host exoplanets – in other words, planets that lie beyond our own solar system. The satellite uses a photometer on its telescope to measure the dimming of the starlight caused by a transiting planet and will provide scientists with the high-precision transit signatures needed to measure its size. This data will provide key insight into the formation and evolutionary histories of these planets.

As part of the CHEOPS project, Almatech was placed in charge of all structural components. The work involved the design and construction of the satellite’s tubular main structure, made of carbon fibre reinforced plastics (CFRPs), as well as the titanium brackets and junctions holding its primary and secondary mirrors. These mirrors cannot be adjusted in flight, so their support needs to be rigid and offer high stability over the range of temperatures experienced in space.

Another example is BepiColombo, a joint European/Japanese mission to Mercury, which is already making its journey to our inner neighbour. Launched in October 2018, BepiColombo will start orbiting the least understood planet in our solar system in late 2025. The mission comprises two spacecraft: the Mercury Planetary Orbiter (MPO) and the Mercury Magnetospheric Orbiter (MMO). While gathering data during its one-year mission, the MPO will endure temperatures in excess of 350°C.

Almatech designed and optimised a baffle that protects the MPO against heating to more than 270°C. It also protects the laser receiver of a built-in altimeter against the heat of the sun. The components included a very fine aluminium mirror used to deflect rays of sunlight. “The shape of this mirror was given [and] the tolerable roughness was specified at 4 nm [nanometres], regardless of any external influences,” says Blecha. “By comparison, the diameter of one aluminium atom is 0.25 nm.”

Finally, the Solar Orbiter is a collaborative mission between the ESA and the United States’ National Aeronautics and Space Administration (NASA) to study the sun and its outer atmosphere. Scheduled for launch in 2019, the spacecraft will observe the sun’s atmosphere and combine these observations with measurements taken in the environment surrounding the orbiter. It will provide insight into fundamental physical processes, studied under conditions impossible to reproduce on Earth and unfeasible to observe from astronomical distances.

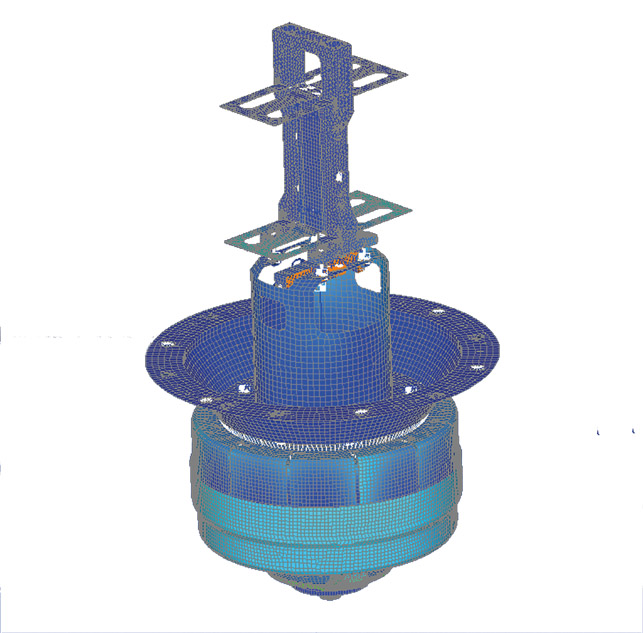

A Spectral Imaging of the Coronal Environment (SPICE) instrument located on board the Solar Orbiter will observe both the solar disk and the corona, in order to characterise plasma properties at and near the sun. For this instrument, Almatech designed a slit- hanging mechanism, which moves the shutter by deforming parts rather than sliding along guiding tracks. “This is vital because particles created by abrasion would, over time, disable the optical instrument, and cleaning is impossible,” says Blecha.

Meshed model of the slit-changing mechanism for analysis in Femap

Testing the digital twin again and again

For many parts, Almatech’s role is to optimise existing designs. The CHEOPS telescope structure, for instance, needed to be reduced in complexity and weight while retaining structural strength.

“Because all components we create are unique and need to function for many years without any maintenance or cleaning, development cycles take longer than in terrestrial designs,” explains Blecha. “Although the shape of the baffle for the BepiColombo orbiter was given, it took us four years to arrive at the final hardware.”

A similar period was spent developing the slitchanging mechanism for the Solar Orbiter, with the team contracted to provide the entire development from first idea to final hardware. The main reason for extended development cycles is the huge number of tests performed to ensure that all requirements will be met, in all situations, over the lifecycle of components.

Within a development cycle, several physical prototypes are built and tested as well, but Almatech performs the vast majority of these tests in the virtual world, using a digital twin of the component under scrutiny. For this purpose, the space-grade equipment designers use Femap software from Siemens PLM Software, in conjunction with the Nastran solver to simulate performance, starting at very early phases of product development.

“The various model analyses provide proof to clients and authorities that the complex devices will perform as required under the anticipated conditions,” says Blecha.

“They are also instrumental in our efforts to reduce mass without compromising stability.”

Nastran is a premier finite element method (FEM) solver for computational performance, accuracy, reliability and scalability. It includes powerful solutions for linear and nonlinear structural analysis, dynamic response, acoustics, rotor dynamics, aeroelasticity, thermal analysis and optimisation. “The advantage of having all these solutions available in a single solver is that input and output file formats are the same for all solution types,” says Blecha.

This single user interface is key to completing the task of calculating the effects of vibrations, noise, temperature and temperature changes on the parts and, at the same time, optimising their mass. “Our aim is to get a good balance between mechanical and thermomechanical aspects, to find the best possible solution,” says Blecha.

Before starting to produce real parts, the Almatech experts reiterate all types of quasi-static, frequency response and thermoelastic analyses of the software model and test physical prototypes using shakers. “We almost invariably encounter opportunities for improvement, and using Femap makes it easy to reiterate the simulation process,” Blecha adds.

Fast iterations proved particularly useful in the optimisation of the main structural body of the CHEOPS satellite. Temperature variations in outer space can potentially cause dimensional changes detrimental to the function of the telescope.

“Using Femap for thermomechanical simulations, we were able to identify and address these issues early,” says Blecha. “Taking advantage of Femap’s capability for a wide range of analyses allowed us to steady the focal distance of the telescope, while at the same time reducing the mass of the components.”

almatech.ch | siemens.com