PTC CEO and chairman Jim Heppelmann addresses LiveWorx attendees

For manufacturing companies of all kinds, the ‘digital thread’ seems pretty promising, with its purported benefits of improved product quality, reduced cost and increased productivity.

The idea of a continuous, seamless strand of data, connecting every stage of a product’s lifecycle, is by no means unique to PTC.

Oracle, IBM, Aras and others are all banging the same drum. But it’s certainly one that plays rather well with the company’s overall strategy, neatly tying together an increasingly diverse product portfolio.

So it wasn’t a big surprise to see the digital thread take centre stage during PTC chief executive Jim Heppelmann’s opening keynote at the company’s LiveWorx annual user conference in Boston this June.

As he told attendees, “A digital thread means that information that was originally created for one purpose – say, an engineering prototype – gets reused for many different purposes. In this way, the digital thread weaves its way across the value chain.”

In other words, and as PTC executives see it, the data relating to a product designed in its 3D CAD product Creo should subsequently flow into its product lifecycle management (PLM) product Windchill.

From there, it can provide the basis for newer applications on the smart factory floor, using the company’s Internet of Things (IoT) platform ThingWorx and its augmented reality (AR) toolset Vuforia.

LiveWorx – a case in point

This isn’t just smart marketing-speak, either: PTC was able to present as evidence a number of large, industrial customers at LiveWorx for whom the digital thread idea seems to make sense.

One of them is Volvo Group, the global manufacturer of trucks, buses, construction equipment and industrial engines.

“There are two main reasons for our interest in the digital thread. The first is quality, which has always been a major focus for our company; and the second is the cost of managing great product diversity,” said Volvo Group’s manufacturing innovation and technology manager Bertrand Felix.

In 2018, he explained, Volvo Group built some 260,000 trucks, with almost every single one configured slightly differently. Windchill thus provides the ‘recipe’ for each and every truck, many parts for which are designed in Creo.

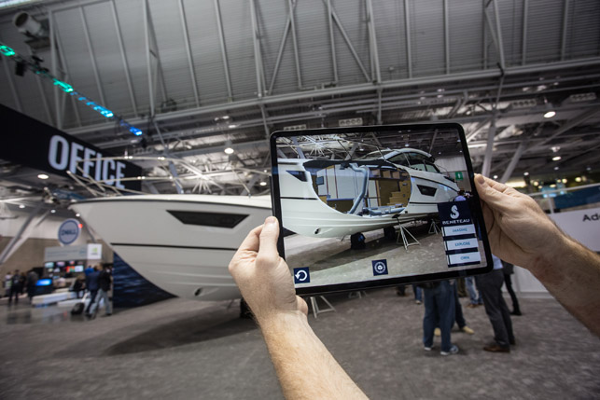

More recently, Volvo has equipped factory-floor staff with iPads that overlay their view of an engine with information about the inspection tasks they need to perform, using ThingWorx and Vuforia.

“We are convinced that, through a solid and trusted digital thread, with consistent data from design to production down to aftermarket, we can enable operators to receive the right instructions, at the right time and matching the right product,” said Felix.

LiveWorx attendees get to grips with augmented reality

LiveWorx – product news

For PTC to successfully sell this digital thread vision to more customers, of course, it must persuade them that each product in its wide portfolio stands on its own merits. To do that, it must keep them all moving along at a steady clip, in development terms.

While Heppelmann’s LiveWorx keynote was notably lacking in big product news announcements, many emerged during the conference and over the weeks following the event.

There’s the release of Creo 6, for example, which introduces new simulation capabilities with Creo Simulation Live, thanks to PTC’s tie-up with simulation specialist Ansys. Creo 6 also includes new AR capabilities with Creo AR Design Share and new features that enable users to design with additive manufacturing in mind. (Read our full review of Creo 6 at tinyurl.com/D3DCreo6).

On the PLM front, there was the news that Windchill will be made available on the Microsoft Azure cloud platform. In addition, PTC’s Integrity tools for application lifecycle management and systems engineering will be integrated with Windchill and rebranded with the Windchill name. It’s a clear nod to the world of smart, connected devices, where the operating systems and software updates that a product relies on need to be managed just as efficiently its mechanical components.

For Vuforia, there’s the introduction of Vuforia Expert Capture, which enables employees to create step-by-step instructions for colleagues to follow, by performing tasks – setting up a piece of machinery, for example, or performing a repair on it – wearing a Microsoft HoloLens head-mounted device (HMD).

With Vuforia Engine 8.3, meanwhile, PTC is combining AR with artificial intelligence (AI). The point here is to enable products or machines to be automatically recognised during an AR experience, even from difficult angles or in poor lighting, based on the customer’s 3D CAD model for it – another good example of the digital thread at work.

Finally, on ThingWorx, there was the announcement that version 8.5 is due to be made commercially available later this summer.

A big focus here is making it easier for customers to deploy industrial IoT applications, by offering more pre-built and pre-configured capabilities in the platform.

Another is service automation, with sensors on a product already in use by a customer alerting its manufacturer to any potential issue – an electrical fault with an office-block elevator or a factory-floor bottling machine that is running more slowly than usual, for example.

In this way, manufacturers can build their service revenues, through offering more responsive maintenance and repair services.

Entrance to the event’s 200,000 square foot Xtropolis Exhibit Hall

In summary

In 2018, PTC used LiveWorx to focus on its ThingWorx and Vuforia solutions, both acquired technologies, to a far greater degree.

This year’s event, by contrast, took a more holistic view of how the different parts of the PTC product stack fit together, enabling the digital thread and, in particular, helping manufacturing employees in their day-to-day work.

All in all, it was a confident performance by a company seemingly in good shape to take advantage of the significant opportunities ahead. Heppelmann certainly didn’t appear to lack ambition, telling attendees, “I want to make it easy to decorate the industrial world with real-time information that your workers need to be as safe and productive as humanly possible. That would be hugely transformational.”

Brian Thompson, senior vice president, CAD segment at PTC

Interview with Brian Thompson SVP CAD Segment, PTC

“There’s something special going on right now in CAD,” says Brian Thompson, senior vice president of the CAD segment at PTC. Customers, he claims, are starting to get a real sense that a mature engineering practice, built on strong CAD and product lifecycle management (PLM) products, is critical to their overall digital transformation strategies.

“They’re finally seeing that link and that’s forcing them to go back and rethink their processes, right at the core, in engineering, where the digital thread begins,” he says.

At the same time, he adds, a host of new technologies are coming down the line that promise nothing less than a ‘renaissance’ in industrial design, and will ultimately assist those customers in identifying better ways to compete, increasing internal efficiencies and getting products to market faster.

There’s plenty to dissect here and there’ll be plenty of engineers who don’t see that kind of thinking at work within their own organisations. But the signal that PTC wants to send to the market is clear: the company’s strength (and its value to customers) lies in the sum of its various parts – CAD, PLM, Internet of Things (IoT) and augmented reality (AR). While IoT and AR may be seen as growth drivers for the company, it’s still the mainstay CAD and PLM products that account for the vast majority of revenues. So tying them all these products together with a compelling overall message makes definite sense.

What’s indisputable here is that CAD technology is changing fast and that Thompson and his team will need to work hard to incorporate new developments into Creo. Take, for example, the integration of Frustum’s generative design technology, acquired in November 2018. This will debut in Creo 7, now less than a year away.

Thompson concedes that there’s always potential for slippage on projects of this kind, and he certainly won’t rush things, but he’s confident his team is on track. “We refuse to deliver a point solution to the market. I will not do that,” he says. “We’re going to deliver a solution to market that’s deeply integrated with Creo, so that every customer who wants to can get access to the technology as part of their core workflow and not be forced to leave the core design environment that they use every day in order to get the benefits of what generative technology can do for them.”

Some of the best AR applications rely on data that originates in CAD, say PTC execs

Simulation is also a vital part of this renaissance picture, says Thompson, adding that it’s been great to see how Creo Simulation Live, powered by technology from Ansys, has been received by customers. “There’s a huge amount of interest around this,” he says.

So much interest, in fact, that the company has taken the decision to back-port the live simulation capabilities into Creo 4.0, in order that a wider group of customers can experience it for themselves, without having to upgrade to Creo 6, as Jim Heppelmann revealed on the company’s second-quarter earnings call with financial analysts in April.

Looking ahead, once the integration of Frustum is complete, its AI-driven generative design capabilities will combine with Creo Simulation Live, to enable customers to first automatically generate a design and subsequently iterate it to reach the best end result, all directly within Creo.

At the same time, PTC has also added design for additive manufacturing and AR-enabled design review to Creo, on the basis that the CAD product that best encapsulates this renaissance, and incorporates as many of the new technologies as possible without forcing users to rely on point solutions, will ultimately win the battle for customers’ attention and budgets.

In short, there’s more of a buzz around CAD at PTC than there has been for some time. Heppelmann admitted as much on that recent earnings call, saying, “Our long-term view of the CAD opportunity is more bullish now than it has been for years.”

Thompson, meanwhile, is buzzing. “I’m really excited, but I’m trying not to be too crazy about it all,” he says. “But customers are really paying close attention, there are all these new technologies, and I feel like we’ve got some serious mojo going.”