Sponsors such as Carbon showcased new tech and materials in their own rooms as part of AMUG

AMUG has had a nomadic history as each year it caters to an ever-growing number of attendees.

This year it was held in St Louis, Missouri, and attendance topped 1,000 3D printing users for the four-day event – including some 40 per cent first time delegates excited to see what all the fuss was about.

The opening remarks from AMUG president Mark Barfoot suggested that you would “only get from this event what you put into it” and, with the event so focussed on worthwhile networking, this rang true.

All industries and knowledge levels were represented, from dental to the Department for Defence, and with every aspect of the technology catered for at its onsite exhibition hall, it was a comprehensive technology showcase.

Given such rapid growth the event is morphing into a new form, with the central mainstage presentations and networking events forming a hub around which the major 3D printing vendors can base their own user events.

With high-level sponsor vendors each occupying individual rooms they were able to welcome customers, show off their latest hardware and hold their own presentations. Given that this meant up to 18 presentations taking place at any one time, there was a lot to fit in.

Hands-on training was also catered for on each day, giving attendees the opportunity to try out Netfabb’s STL file fixing software, attempt silicon moulding and polyurethane casting, learn how to apply hydrographic paint finishes to parts, or even take part in some metal casting.

Industry insights

Despite the keynote sessions featuring a similar line-up to the previous year, the topics were varied enough to give fresh insight into the industry at large and developing technologies.

Analyst and AMUG board member Todd Grimm returned to give a presentation on the ‘age of innovation’, which proved a whirlwind tour through the market in the past year and the impact of 3D printing’s collapsing hype bubble.

While lots of investors will have been burned by the crash in 3D printing shares, Grimm was positive that all was not lost.

Pointing to Gartner’s now famous graph of the hype cycle, for emerging technologies, he proclaimed that there is still great potential to emerge from the 3D printing sector as it moves through the ‘Trough of Disillusionment’ and up to the ‘Plateau of Productivity’.

The main difference will be that developments in 3D printing technology might not be as visible as in previous years, where companies rushed to showcase 3D printing projects for the benefit of good marketing.

However, behind closed doors, Grimm expects that the next decade will be one of tremendous development.

Special effects

Another returning speaker was Jason Lopes, lead systems engineer for Hollywood visual effects studio Legacy Effects.

The sheer amount of work that Lopes and the Legacy Effects team is able to get through, while still maintaining jaw dropping levels of detail, continues to amaze.

Despite presenting the keynote at the previous year’s event, the breadth of projects in the last year and new technologies used, such as Carbon’s M1 printer, made this an impressive talk.

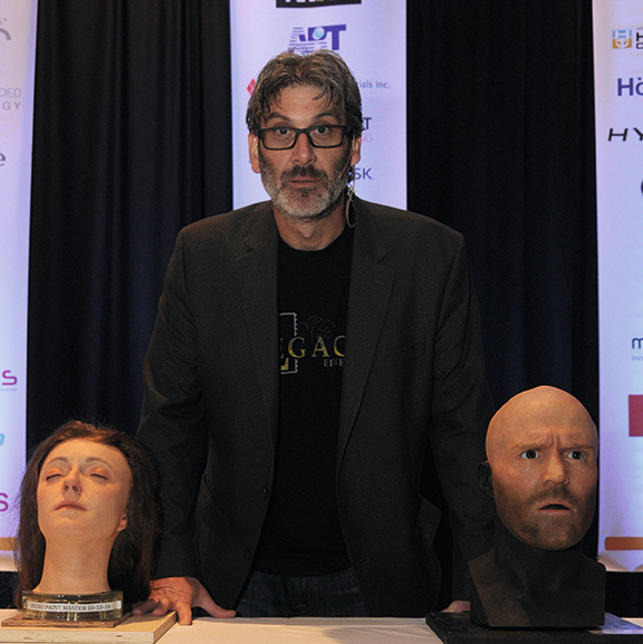

Keynote speaker, Legacy Effects’ Jason Lopes, with two digital doubles

Much of the presentation revolved around creating lifelike masks and mannequins of humans for use on the big screen.

While 3D scanning is invaluable to this work, Lopes disclosed that full head life casts were still favoured, given the time constraints for scanning (as little as 12 minutes with an A-list celebrity) and that they capture every minute detail that can be reassessed by the artists at a later date.

This technique was displayed as part of the work Legacy produced for a Super Bowl commercial featuring comedian Stephen Colbert — a frantic two week physical and mechanical project, overlaid with digital effects, all for a seamless 15 second end product.

As Lopes professed, “We don’t have a go-to book for what we’re doing next!” making his work a challenging spectacle that the entire audience felt caught-up in.

Panel discussion

What should have been an epic panel discussion between senior figures from the event’s 12 major sponsors — featuring the likes of 3D Systems founder Chuck Hall, Carbon co-founder and CEO Joe DeSimone, HP Worldwide 3D Printing director J Scott Schiller, and Stratasys’ Rich Garrity, senior VP and GM of vertical solutions — was the only aspect of the event to fall flat.

The sheer number of people involved sadly limited the amount of time for each panellist to make their point, proving a missed opportunity, as few were willing to agree on how to best tackle industry problems like machine robustness, or industry adoption, and a simmering debate was avoided.

Hands on sessions gave the chance to learn new 3D printing technologies

Regardless, the best conversations at AMUG were happening off stage, where first-hand we witnessed nagging problems with a machine solved over the lunch table; advice on post processing handed out at the bar, and users finding completely new solutions and placing orders for new 3D printers in the exhibition.

We can’t think of an event quite like it, but as it looks certain to grow yet again in 2017, we only hope it can maintain its magic.

The latest in 3D printing from the US Additive Manufacturing Users Group

Default