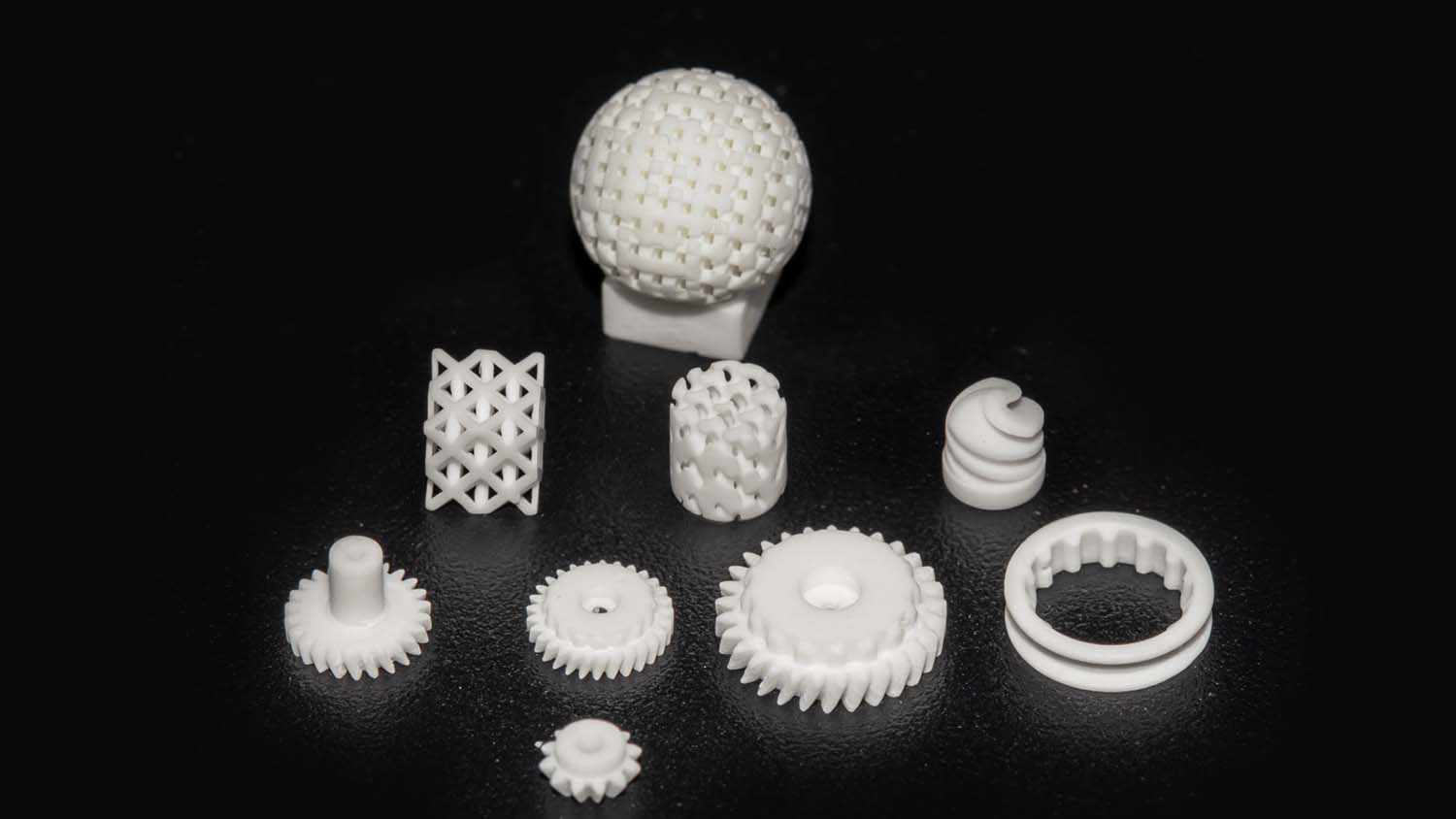

Boston Micro Fabrication (BMF) has unveiled its microArch S230 3D printer, the latest addition to its roster of micro-precision 3D printers.

This next generation version of BMF’s highest resolution system is designed for applications that require ultra-high resolution prints, down to 2μm, with accuracy, precision and speed.

The 3D printer uses BMF’s patented Projection Micro Stereolithography (PµSL) technology, a technique that allows for rapid photopolymerisation of an entire layer of liquid polymer using a flash of UV light at micro-scale resolution, but with a larger 50 x 50 x 50mm build volume and up to five-times faster prints than previous models in the 2μm series.

BMF adds that other key features of the microArch S230 include active layer levelling, automated laser calibration and the capacity to handle higher molecular weight materials with viscosities of up to 20,000 Cp, allowing it to offer stronger functional parts.

The printer is compatible with a growing portfolio of engineering and ceramic resins suitable for end-use parts, including three new materials:

- AL (Alumina) Ceramic – A biocompatible and chemical-resistant ceramic resin meant for high temperature, high strength and high stiffness applications such as tooling (injection molding), casing and housings and medical devices

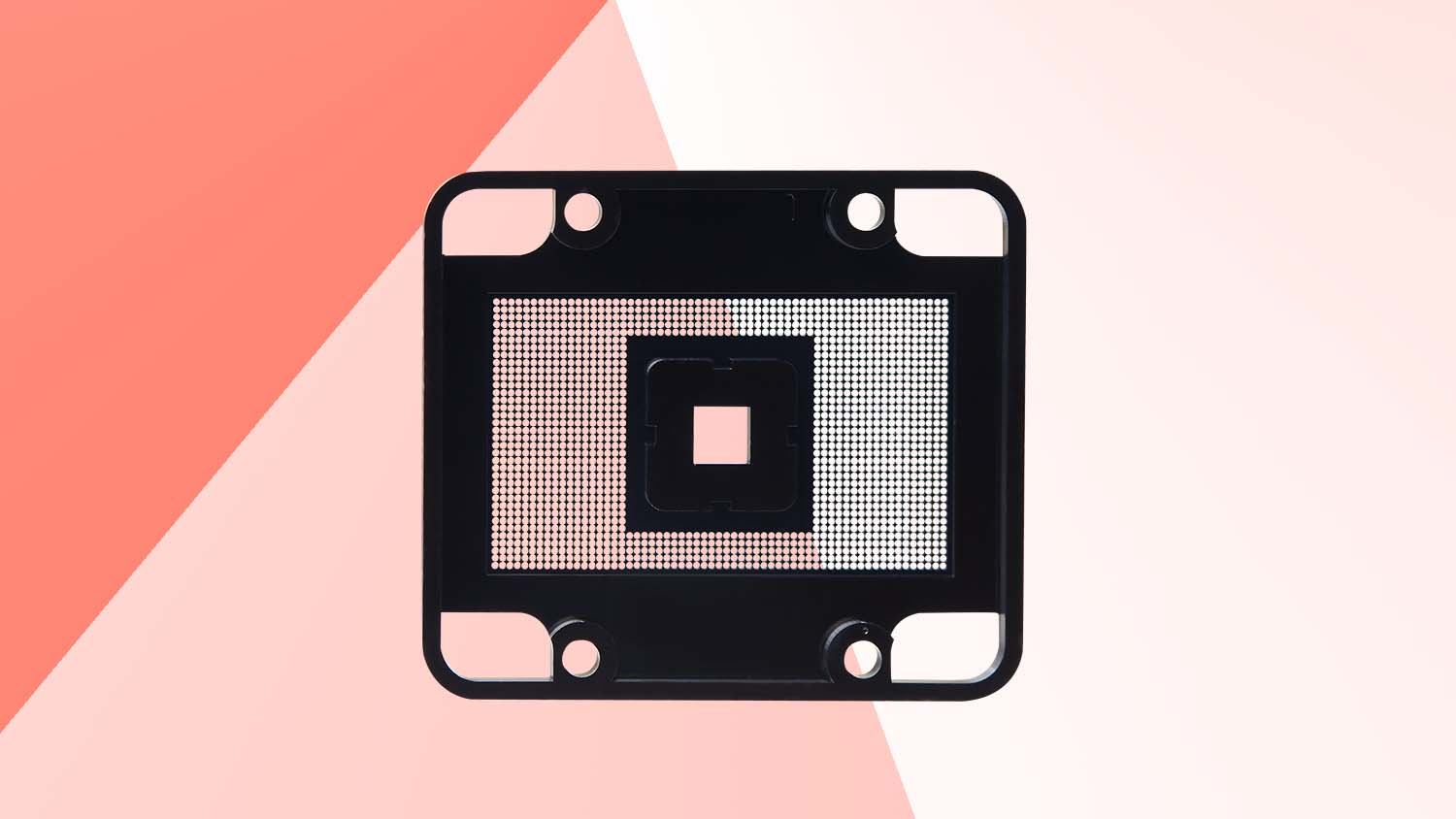

- HT 200 – A durable, high-temperature and high-strength resin that can be soldered, and designed for end-use in electrical connectors and electrical components

- MT (Magnesium Titanate) Ceramic – The combination of high dielectric constant and low dielectric loss make MT Ceramic suitable for millimeter wave applications such as antennas, wave guides and other electronic components

“The miniaturisation trend continues to dominate nearly every industry, but as parts get smaller, they become harder to design, more expensive to manufacture, and generally more complicated to put into production. Not to mention, technological barriers had previously made additive manufacturing out-of-reach for most use cases requiring small parts,” said BMF CEO John Kawola.

“We changed that notion and brought 3D printing to industries that once deemed it impossible, and this new addition to our portfolio – the most advanced of our highest-resolution printers yet – will open even more doors for new applications on the smallest scale.”