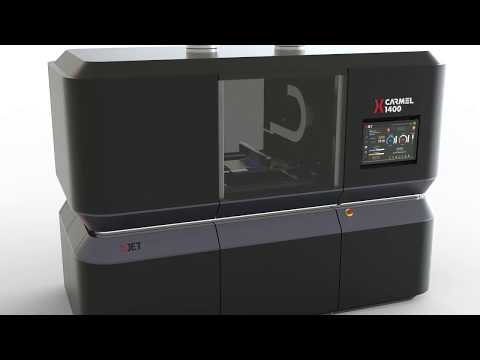

The first of XJet’s nano-particle jetting 3D printers is already in a production setting with many more set to follow, as the Israeli company ramps up the production of its Carmel 1400 and 700 systems.

It’s an exciting technology, which it is hoped will soon make multi-material printing of metals and ceramic in the same part a possibility on an industrial scale.

Featuring the company’s patented NanoParticle Jetting (NPJ) technology, the printer eschews the costs and safety problems of 3D printing with powders and instead suspends the metal or ceramic particles in a solution, before layering them and a support material from high-resolution print heads.

https://giphy.com/embed/xUOxf6o7K90diQsH84

A 300°c build chamber evaporates the liquid ‘ink’ fusing the part into a solid, while the soluble support material is removed easily once removed from the printer, before the green part is finished in a kiln.

“We designed the system to fit production,” said XJet CEO and founder Hanan Gothait.

“From our analysis, what’s really preventing people from doing production is the part quality – powders are a big obstacle, because of safety issues and cost issues, and so on – so we wanted to remove powders and do super fine details and with any geometry.

“You don’t need to recycle the powder afterwards – there’s no powder bed! You just put in a [material] cartridge.”

“You don’t have to care about the design – you con’t care about the orientation anymore – before you needed to put a lot of effort in to how you design and orientate the part. Now you just place it on the tray (we’ve automatic software that does it) and push print.”

The parts on display at the Formnext launch were all without any post processing or machined finishing and looked impressive, while Gothait says that XJet’s system software takes care of all design issues associated with part shrinkage in kilns.

The first materials will include stainless steel 316l, zirconia, although the process will quickly add new materials, with Gothait seeing no reason why the process will struggle with any of the tougher engineering materials.

“If you get [the materials] as a powder then it’s not a problem. In fact it’s easier – if you do it with lasers, there are a few metals they cannot do because of if the metal reflects the laser, oxidises or reacts. In our case you just take the powder, put it in a furness, that’s standard in industry: MIM guys have been doing it for 150 years already.”

“In the future we will introduce multi-materials – this is really possible,” said Gothait, adding “Yeah! Sure!” when asked if that meant ceramics and metals together in the same build. Already the Carmel machines are printing two materials (the solid and the support), so it should be easy.

“The printing is the easy part, then sintering is more challenging, because you have two different co-efficients of expansion and all that – but there are many ways of solving that,” said the positive CEO.

“This is a very exciting period at XJet,” concluded Gothait. “Until now, our many successes have been in the laboratory; now we’re going out into the real world.”

The first Carmel AM system has been installed at Oerlikon in Germany and is already running. During December, a second system will ship to Youngstown Business Incubator in the USA for installation in January 2018.

Both sites will perform field tests on the XJet systems with a focus on using ceramic materials to produce parts for a variety of industries.