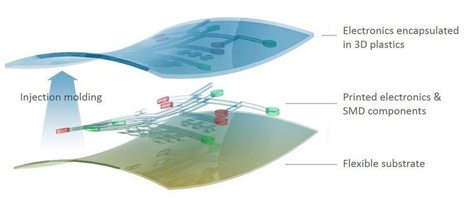

Greater design freedoms will become available with lighter, curved and flexible structural shapes now containing the devices electronics

Finnish electronic devices manufacturer, TactoTek, has unveiled details of its new manufacturing process, which enables light, thin designs that incorporate electronics into structural plastics

The company is able to insert electronic components into injection moulded parts, including LEDs for sophisticated lighting, sensors, ICs, and printed touch controls in both rigid and flexible designs, .

With integrated 3D printed electronics still some way off, this method, using a flexible substrate to encapsulate electronics into a more traditional injection moulded part, might lead the way for new wearables and electric vehicles technology.

While we wait on integrated 3D printed electronics, this method uses a flexible substrate to encapsulate electronics in a more traditional injection moulded part

With the TactoTek solution, brands can create 3D control panels with sophisticated illumination and touch controls that reduce depth and assembly time.

Flexible wearables that distribute electronics throughout the device instead of relying on a thick central computing unit will also be viable; while the use of lighting on product will be easier to achieve through the elimination of light pipes, enabling innovative shapes and increasing durability.

“Wearable technology, the Internet of Things and other new applications of electronics cannot be adequately served by the 100-year-old components-in-a-box approach,” said Dr. Peter Harrop, chairman of IDTechEx. “Lightweight, shaped, rugged, structural construction, where TactoTek excels, is essential. It will be invaluable in electric vehicles, for example.”

A reverse of a prototype product showing examples of integrated circuitry and lighting components

To facilitate customer transition to structural electronics designs, TactoTek’s Product Creation team works with customers to adapt designs to structural electronics that evolve into prototypes optimised for mass production.

“Whether the market is IoT, wearables, or vehicles, the next generation of electronics must support the ever-increasing demand for incorporating intelligence into designs while supporting rapid product cycles, and TactoTek was established to meet this need. We have developed our capabilities in cooperation with select industry leaders and the industry is moving in our direction,” said Jussi Harvela, CEO of TactoTek.

TactoTek prototypes and manufactures products in its Oulu, Finland, factory that includes a complete range of production capabilities; while mass production can be performed by TactoTek or licensed to one of its certified facilities.