https://giphy.com/embed/46zOXPT5Obr7Kis8Js

Velo3D has announced the general release of its end-to-end metal additive manufacturing (AM) solution comprised of the Sapphire system, Flow print preparation software, and Intelligent Fusion technology.

A dual laser powder bed 3D printing system, the 3D printer has been designed for high volume manufacturing, with the automated bed change-overs and consumable swap-outs that you’d expect from a brand new machine in the additive manufacturing space.

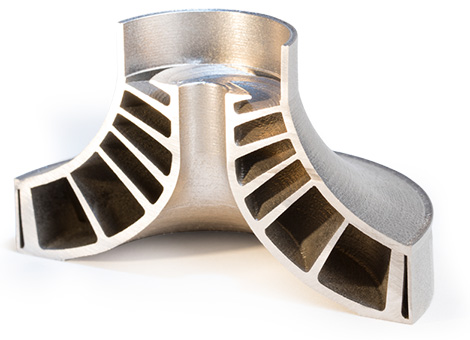

However, Velo3D has some interesting capabilities in the form of its abilities to build more complex geometries with overhangs that are less than five degrees and large inner diameters without supports.

A shroud impeller printed by Velo3D

In-situ process metrology enables closed loop melt pool control during builds, while its Flow proprietary print preparation software includes support generation, process selection, slicing and simulation of complex part designs to validate execution feasibility before the build.

In addition, deformation correction technology enables the user to produce parts without the need for iterations, achieving what Velo3D claims as a first print success rate of ‘up to 90 per cent’.

Velo3D Sapphire dual laser powder bed 3D printing system

“Four years ago, we set out with the bold vision of creating technology that could manufacture parts with any geometry to take additive manufacturing mainstream,” said Velo3D founder and CEO Benny Buller.

“Our approach relies on creating deep insights in physics fundamentals, enabled by research, characterizing and understanding of core mechanisms, developing intelligent process control through software simulation and in-situ metrology.

“Today, Velo3D is working with some of the top OEMs and service bureaus creating parts that were once considered impossible.”