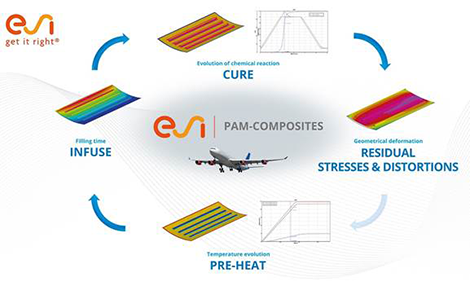

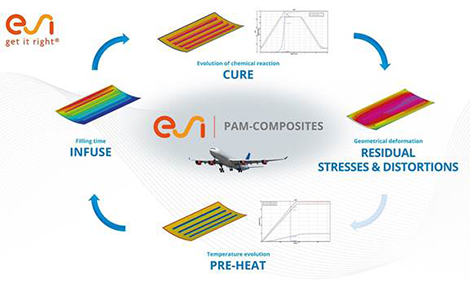

PAM-Composites can predict the manufacturing chain for developing components, such as a defect-free aeronautic composite fuselage panel

ESI is aiming to give designers and engineers more control over complex composites workflows through its new PAM-Composites 2016 software package.

Enabling the prediction, analysis and correction of manufacturing defects for composite structural components across the manufacturing supply chain, the solution provides a full suite of modules covering manufacturing processes.

ESI suggest that the new enhancements will enable users to precisely identify the origin of defects and manufacture composite parts with a higher degree of accuracy; reducing material waste and obsoleting the need for costly and time consuming trial and error approaches.

Using the PAM-Composites solution, simulations can be tailored to the exact nature of the composite material and their unique shop floor environment to improve process stability and possibly reduce manufacturing defects for a vast range of composites manufacturing processes. These include: draping, thermoforming, Liquid Composites Molding (LCM), Resin Transfer Molding (RTM), and curing, as well as two new robot draping processes: Automated Fiber Placement (AFP) and Automated Tape Layering (ATL).

In PAM-COMPOSITES 2016, the newly introduced Design of Experiments (DoE) functionality automatically analyses variations in the composite material and manufacturing process parameters to allow process and design engineers to optimise key influencing parameters and improve process stability.

A new Die Spotting functionality allows existing tools to ‘automatically morph’ to ensure a perfect contact with the part.

This should help avoid the bridging effects often seen with thermoformed organo-sheet components where resin migration and lack of compaction leads to visible defects. It also allows engineers to avoid the incidence of areas with low fiber content or race tracking during resin injection or infusion.