Delcam’s chief executive Clive Martell welcoming delegates to the summit

This year Delcam held its Asian Technical Summit (ATS) in Bangkok, Thailand. This event, the 13th in an annual series, brings together members of the press from that region in order to present its latest news and showcase customer success stories.

In fact, earlier this month Delcam announced its 45,000th customer – PT Astra Honda Motor in Indonesia, which recently ordered seats of the PowerMILL CAM system and PowerSHAPE design software from the Delcam Indonesia subsidiary, plus the Delcam Electrode and FeatureCAM Wire EDM programs.

DEVELOP3D was once again privileged to be invited to the ATS – the only publication not from Asia.

As the event consisted of customer presentations as well as two customer visits – it was really great to get a look in and actually see first hand how Delcam’s range of CADCAM software is being used by its customers in Asia.

The two day event kicked off on 21 August by Delcam’s chief executive Clive Martell, who introduced its activities in Asia and revealed how the company has grown globally over the years.

Martell was followed by various Delcam employees, from its HQ in Birmingham, UK as well as Thailand, China and India, who spoke about the company’s professional services and software updates including FeatureCAM 2014, Partmaker and PowerINSPECT. However, the big news seemed to be Vortex – a unique high speed roughing technology that is to be featured in PowerMILL, FeatureCAM, Delcam for SolidWorks and PartMaker.

Vortex, for which Delcam has a patent pending, has been developed by the company specifically to gain the maximum benefit from solid carbide tooling, in particular those designs that can give deeper cuts by using the full flute length as the cutting surface. It can be used for two- and three-axis roughing, three-plus-two-axis area clearance and for rest machining based on stock models or reference toolpaths.

This video on DelcamTV explains Vortex machining in more detail:

//www.youtube.com/embed/HVS_lnnxdbg

On Wednesday afternoon we also took a short bus journey to Mazak, a Japanese machine tool manufacturer. Founded in 1919, the company has a worldwide network of 77 technology centres including Mazak Thailand, which was founded in 2003. It was interesting to see the facility and the various machines in action including CNC turning centres, vertical machining centres, multi-tasking machining centres and laser processing machines.

Just one of the range of machines at Mazak Thailand

On Day Two we had presentations including software demonstrations on PowerSHAPE, ArtCAM, new dental and orthotics developments and PowerMILL robot interface.

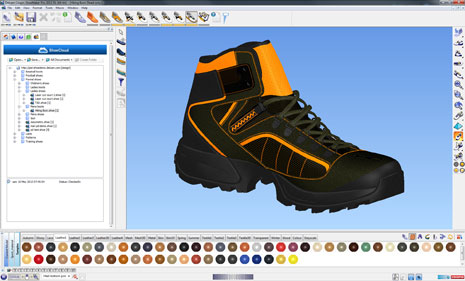

There was also an interesting presentation on Delcam CRISPIN, CADCAM software for the footwear industry, given by Graham Vollans, the business development manager of Delcam CRISPIN, a Brit who is now based in Bangkok.

Delcam CRISPIN has launched project management and collaboration software for the footwear industry called ShoeCloud

Delcam claim that CRISPIN is the only supplier able to provide a complete solution for the design and manufacture of lasts, uppers and soles. The highlights of the 2014 release include a more intuitive interface, a new release of the ShoeCost footwear costing software, the new ShoeCloud project management system and the latest release of the ShoeMaker 3D design software.

Together with customer presentations from ABB Robots, Harbin Aircraft Industry Group and Bangkok Rubber, on Thursday we were once again bundled into a bus and this time taken to the Thai Summit Group, a leading auto parts manufacturer. We visited three different areas of its huge facility – TSM Mold, TSM Autosport and TSM R&D.

Thai Summit Group’s MD taking us on a tour of the factory with a lady who was interpreting for the English-speaking delegates

On the tour we saw the whole process from the design office where Delcam’s software is utilised to the machines in the factory (some of which are pretty massive especially the metal stamping) that manufacture the tooling and parts.

Touring the Thai Summit R&D shop floor

Overall, Delcam ATS 2013 was a very informative and enjoyable event.

It was a real eye opener, especially for me as I’ve never been to Asia before, to see how companies there operate and use Delcam’s software.

It was also great to hear from Delcam’s Asian customers, those who presented as well as the two we visited, using its software to move forward, increase productivity and remain globally competitive.