Meet Mr Carp – MAP is designing to help you catch these little fellas

Fishing is never going to have the most glamorous of images, but there’s no doubting that it’s hugely popular; popularity breeds competition, and competition means big money is at stake.

MAP is based in Redditch, the home of British fishing tackle, a result of its heritage from the needle-making industry, which was adapted to create fishing hooks.

Specialising in competition level fishing tackle; just like in any sport it’s the upgrades in the hardware that progress what competitors can achieve – this even comes down to the way you prepare your bait, how it flirts with the fishies, and how quick it is to repeat the process.

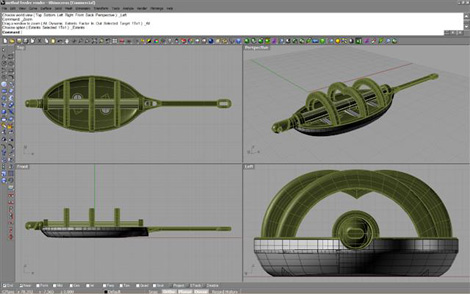

A method feeder, a line feed method designed to provide a weighted grip for the breadcrumb-like bait

Rhino was used to model the mould which helps attach the bait to the Method Feeder

- The ‘Method’ feeder is a special distributor and mould that shapes and attaches the moistened breadcrumb–like bait to the line and an attaching hook

- Although there are similar products on the market, MAP prides itself in redesigning for more reliable and better quality products, so sets about tweaking designs and adding its own influences

- The methods of fishing haven’t really changed in the last 10 – 15 years, so a lot of the concept ideas come from seeing how people are adapting their own techniques

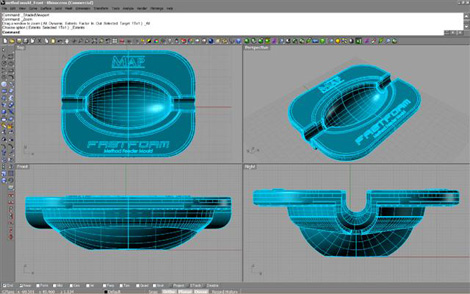

- Most angling equipment is cheap and cheerful, so for the high-end competition gear it has to provide sturdy build quality with accurate weighting – hence the shaping mould that creates an identical Method feeder bomb every time

- The design team works around sketches for products before moving into Rhino 3D to create more accurate models

- Materials are important: For the mould, the plastic internal structure has a rubber moulder over the top to provide grip in the cold wet weather that fisherman seem to love, and a polyurethane coating on the mould inner means that the Method feed won’t stick to the inside

- The model data was sent off to Malcolm Nicholls Ltd who produced a series of rapid prototypes of silicon moulds that could be used to produce working prototypes that MAP’s sponsored professional anglers could test

- Any changes and improvements suggested by the pros are made and the data along with an actual prototype is sent out to China for production

- With some competitions offering up to £500,000 prize money, it’s big business

The Method mould fresh from manufacture

Got a new product, working on a design, or have a concept you want the world to see? Then get in touch here