//giphy.com/embed/PSS6XQBpduHCw

Spatial Corp has announced its latest input to Renishaw’s 3D printing build preparation software, QuantAM, used to generate laser scan paths that fuse the powder layers to additively form the part.

The major change to the QuantAM release for 2017 is the move to the 3D ACIS modeling kernel and away from the reliance solely on an STL representation of the model.

This move to Spatial’s native modeling kernel delivers significant advantages including claimed best-in-class model healing, benefits of precise B-rep and polyhedral hybrid modeling capabilities, as well as the ability to edit the 3D model directly.

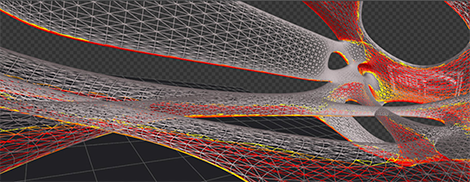

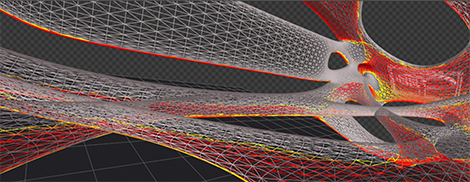

QuantAM adds B-rep and polyhedral hybrid modeling capabilities

A Dassault Systèmes subsidiary, specialising in 3D software development toolkits for design and engineering solutions, Spatial has been a longtime collaborator on the QuantAM software.

“Rather than rely on a triangulated view of the 3D model, a far better approach is to work on the native geometry, preserving the original design intent of the model,” said Brian Rohde, marketing manager responsible for the 3D ACIS Modeler at Spatial.

“By integrating Spatial SDKs into the newest version of QuantAM, Renishaw will continue to ensure the best chance of built-right-the-first-time parts and benefit from Spatial’s 30-year history of innovation.”