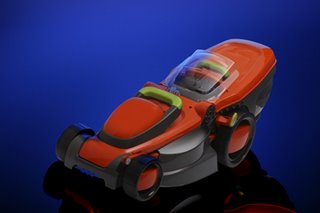

This little Flymo is a prototype put together by ARRK comprising of 25 CNC components in ABS and clear acrylic, whipped together in under a fortnight that allowed for actual field trials to cut grass.

Garden tool manufacturer Husqvarna called upon ARRK to assist in the development of their new rear collection lawnmower, the Multimo 360XC.

After successful trials ARRK was then commissioned to produce vacuum castings to build 15 fully assembled lawnmowers to be used for photo shoots and marketing meetings.

The components were fully finished, textured, assembled and then delivered to the client within four weeks, just in time for the product launch.

Related articles:

HP and Deloitte announce alliance to transform manufacturing

Nvidia delivers first Iray physically-based rendering plug-ins through dedicated online store

Daimler Truck adds remote spare part production with AM

ESI's predictive simulation for automotive panels and developing new lightweight structures

Siemens and SAP announce a new PLM/ERP partnership

MakerBot CloudPrint targets 3D Printing collaboration

PREVIEW // ESI IC.IDO v11.1 - Nvidia Pascal GPU input adds new abilities

Materialise metals 3D printing take to the stage across 10 cities

Advertisement

Advertisement