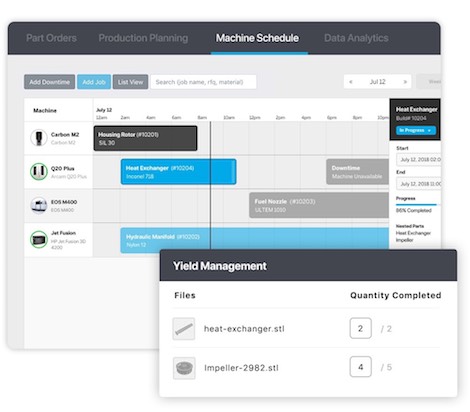

New York-based Link3D has announced its new centralised software platform, Link3D Production Planning System (PPS), for industrial 3D Printing across internal or external additive manufacturing ecosystems.

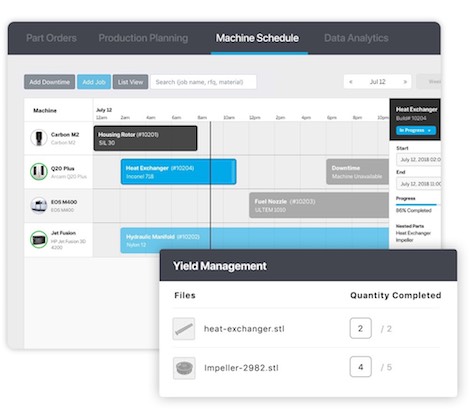

Powered by advanced Build Simulation and machine connectivity, the PPS module aims to help companies reach maximum manufacturing capability using all the additive tools at their disposal.

“Our comprehensive predictive models are made to forecast AM production and costing outputs by accounting for labour, hardware model, AM technology, post-processing and including material science variables like specific gravity and viscosity.” said Link3D CEO & Co-Founder Shane Fox.

“Link3D PPS utilises machine learning algorithms to make recommendations for placing work orders on the correct machines based on machine availability to achieve real-time distributed manufacturing.”

Earlier this year, Link3D announced its first ever blockchain technology for AM in order to provide higher levels of file integrity, security, and traceability to help companies move towards mass adoption of AM.

PPS will also implement the use of blockchain technology to track and trace all data logged and generated to help organisations validate and certify their processes.