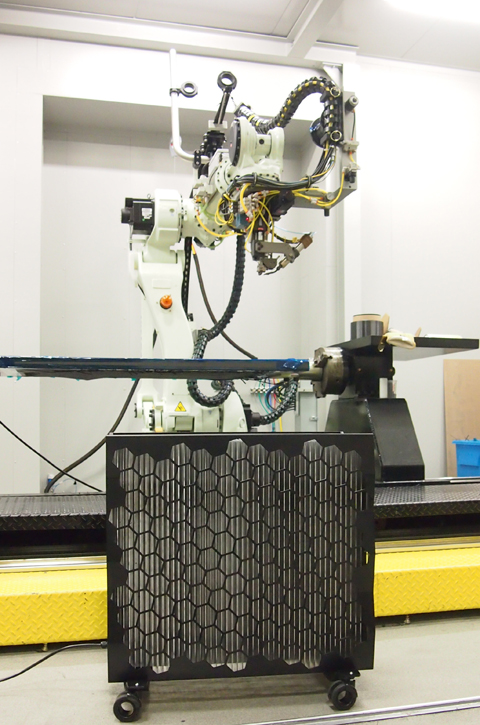

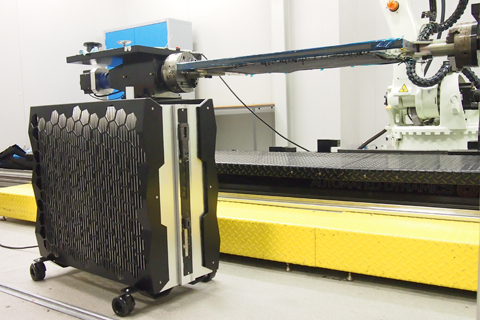

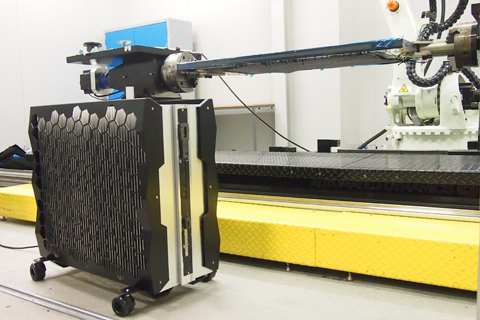

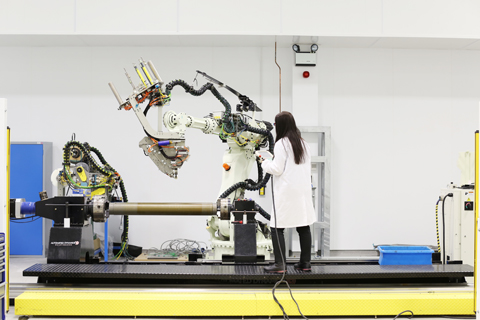

Completely sealed Iceotope workstation on the factory floor, inside the AMRC’s composite centre where dust particles and fibres are a huge challenge for traditional air-based IT equipment.

Iceotope is targeting manufacturers who need to deploy high-performance servers and workstations in harsh and rugged environments.

The company’s patented passive liquid cooling technology is designed to replace air cooling for silent operation and flexible deployment, while protecting machines against dust created by manufacturing processes.

Iceotope workstations are to be trialled in the University of Sheffield’s Advanced Manufacturing Research Centre (AMRC) with Boeing, alongside the Advanced Manufacturing Park where Isotope is based.

Sealed units are designed to protect workstations from carbon fibre dust that is routinely generated by the manufacturing operations in the AMRC’s Design, Prototyping and Testing Centre and on the workshop floor of the Composite Centre.

Iceotope has also developed a data centre facility consisting of sealed server blades immersed in safe, non-flammable coolant, to capture and reuse waste heat for greater efficiency. A data centre facility will soon be installed in the AMRC’s newest development Factory 2050, to assist in the processing of ‘big data’ for a large volume metrology project.

Sam Hyde, a project engineer with the AMRC’s Design and Prototyping Group, said: “The Iceotope system represents a valuable resource for the design and prototyping group. The power available is ideal for computationally intensive work, such as computational fluid dynamics, finite element analysis and 3D rendering.

“It is also useful that the machine is totally silent in operation, unlike similar machines which require a large number of high power fans for cooling. This allows us to keep the machine in the quiet office, and not need a dedicated room for the equipment.”

AMRC IT Systems Manager, Chris Hodgson, added: “Creating HPC facilities within a manufacturing environment can be challenging due to the variety of settings and uses required.

“Servers and workstations need to be protected against hazards such as dust and debris created by manufacturing processes. Increasingly flexibility of location and efficient heat management are also required for office-based computing centres.

“Placing the computing power at the edge of the network also reduces bandwidth and interconnectivity requirements.”

Iceotope claims its liquid cooling technology can also save 40 per cent of the total cost of ownership. It can keep components cool, without the need for air-conditioning equipment and condensation units. It can also turn wasted energy into useful energy, for heating offices or for generating electricity.