https://giphy.com/embed/5b7kjHFNMUHIXqNxt5

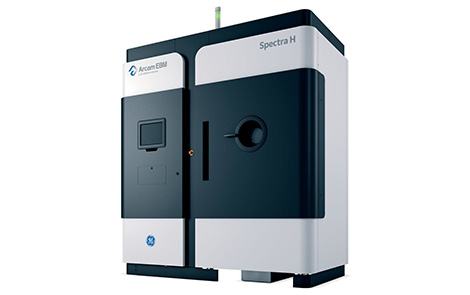

GE Additive has unveiled the Arcam EBM Spectra H, a new metal additive manufacturing system designed to handle high heat and crack prone materials, such as Titanium Aluminide (TiAl).

Initially, the Arcam EBM Spectra H will support both TiAl and Alloy 718 and additional Ni-super alloys will be supported from 2019 onwards. Once GE Additive‘s materials science team finishes exploring all the future opportunities for high heat materials, new capabilities will be introduced, potentially including; nickel superalloys, tungsten, CoCr, stainless steel and metal matrix composites.

A 200 x 200 x 380mm build area will be home to a 6kW HV-unit, which will handle all the pre- and post-heating steps, something GE Additive’s Arcam engineers say will take half the time compared with current EBM machines.

Improved heat management through the incorporation of a moveable heat shield should help keep heat in the build area, while a new layering procedure aims to reduce the need for heating, saving approximately five hours for a full height build.

Arcam’s xQam automatic calibration technology will be integrated, managing the position and focus accuracy and removes need for manual calibration, reducing the set-up process from around four hours down to a reported 15 minutes.

All this adds to GE’s goal of reducing dependency on operators and incorporating automation technologies to improve accuracy, which when coupled with an improved and automated power handling process for the Spectra H should help reduce errors and increase throughput.

“This new system shows our commitment to developing industry-leading additive machines, materials, and services,” said GE Additive president and CEO Jason Oliver.

“We remain focused on accelerating innovation across sectors and helping the world work smarter, faster and more efficiently.”

Arcam’s general manager, Karl Lindblom, added that it feels the Spectra H is an ‘amazing system’, able to push the abilities of EBM technology.

“Spectra H is the result of really hard work by a cross-functional team from across the GE Additive family, supported by insights and feedback from a handful of internal and external customers,” continued Lindblom.

The new system is available to pre-order, and will be manufactured at Arcam’s plant near Gothenburg, Sweden with expected delivery from Q4 2018 onwards.