After hitting the web with a nifty little teaser trailer last week (as above), Formlabs has just this very moment announced the next generation of its Form 3D printer devices. Whereas last year’s Form1+ was an iteration of the original, kickstarter smashing machine, the new Form 2 is a pretty different beast – and here it is.

https://youtube.com/watch?v=Ak4kgiSvgN8%3Frel%3D0%26showinfo%3D0

So let’s dig into the details

The Form 2 is clearly a different machine from the Form 1+ we looked at last year.

The new machine has a larger foot print – to bring in some of the new features. Perhaps the biggest news for those looking at this machine for larger components, is the new 40% large build volume (the form1+ build platform is 125 x 125 x 165mm, this should be a bit larger than that), but what’s interesting is the technology that’s driving it.

While the basics of the system haven’t altered (it’s using laser light to cure resin thought a transparent tank), the mechanics have been redeveloped.

Part of this is a new, more powerful laser (which should give you an incrementally quicker build time, but is presumably to help with the large build), and a new build mechanism.

The Form 1 used a tilting movement to separate the resin tank from the print head (hopefully with the layer attached to the build platform). The issue was that in some cases: the opposite could happen, particularly with more heavily used resin tanks, and you’d end up with half your model in the tank, the other half on the build platform.

This is by no means an issue with just the Formlabs machine either, but it’s worth noting.

The Form 2 features a new mechanism and peeling process that slides instead of tilting (which should be more gentle).

There’s also a new wiper blade that passes over the clear base of the resin tank to remove any partially cured material and should give you a greater yield with larger and/or more delicate models. Those small artefacts can interfere with the build process as they remain on the build platform so this shoves them to one side.

Also worthy of note is that the machine also has a heated tank. While the Form 1 model retained a lot of heat from its own operation, it wasn’t consistent – and photo curable resins have pretty strict operating temperature ranges (as someone that ran both the Form1+ in a shed, in the winter, this I know). This should address the issue, giving you more reliable and consistent results.

Additionally, the company is now selling its resins in cartridge form, and while we’re waiting to get our hands on a machine to run our usual tests, it seems that these will allow the machine to refill the resin in the tank – again, enabling the large builds without having to worry about topping up the tank mid-build.

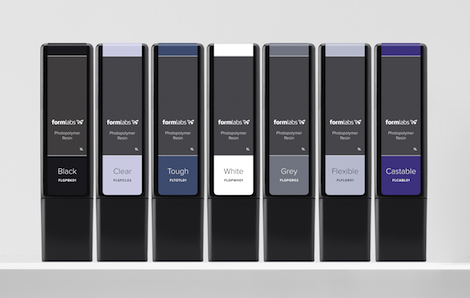

With Formlabs’ expanded range of materials that now includes a tougher resin, a flexible resin as well as a castable alongside the usual colour variants, it looks like a nice little package that’s pretty flexible in terms of what you can build.

In terms of other updates for the Form 2, there’s a few other items worth noting. Firstly, the machine is now wireless enabled with a bunch of customisable alerts and such and you’ll also be able to monitor the machine over the web as well. And last but not least, the control panel has been given an update (from it’s LCD + one button) to a touch panel for managing print queues and viewing print status.

In terms of cost, it looks like the machine is going to retail for $3,499 (with a litre of resin included) and an updated post processing kit. It’ll be available on 22 September and we’re told that there should be a couple of machines on show at TCT next week too!

We’ll reserve judgement till we’ve had a play with one, but for the next generation, it looks like FormLabs has advanced the state of its art and built a machine that moves it beyond the origins and into a machine that’s reliable, consistent and produces killer results. Which is what the professional market wants and needs.

The one thing I’m surprised by? The simple fact that it’s only $100 more expensive.