Formlabs looks to have taken the opportunity of CES to launch a bunch of interesting things. Perhaps the most interesting is the new Rigid resin.

This is the first time that Formlabs has launched a filled resin, promising higher stiffness and a ‘polished finish’.

Filled resins have been around for a good long while and available for SLA machines from a variety of vendors, but the use of them is complex: the particulate needs to be agitated to ensure even distribution so it’ll be interesting to see how this material builds on the Form 2 and what effect it’ll have on the degradation of the build trays (given the abrasive nature of the glass components of the resin).

The other key resin news is a new Grey Pro resin which has been developed to assist with “concept modeling and functional” tests, qualified with moderate elongation and low creep.

Alongside these two materials updates, the company has also partnered up with 3shape – hardware and software specialists focussing on dental and audiology – to put together a solution for the design and manufacture of custom earbuds.

The Formlabs press release has an interesting quote from Formlabs’ David Lakatos “We’re seeing 2018 as the year custom earbuds will be available to most consumers.

“This announcement marks a significant use case for 3D printed mass customization at the consumer level, but the implications of the technology go beyond headphones to include hearables. We’re proud to be part of the growing force behind accessible, affordable, high-quality 3D printing that is making on-demand production of custom earbuds finally possible.”

Yup, Hearables, but that aside, there are some interesting developments here.

Formlabs Audiology

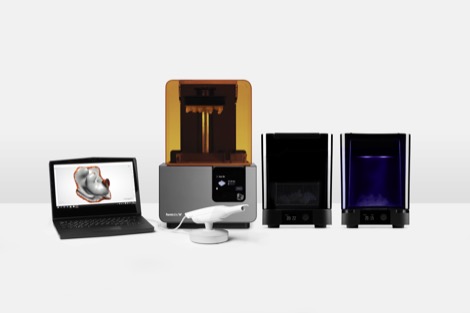

The full workflow stack, Formlabs Form 2, post processing kit and the 3shape Phoenix scanner for your lug ‘oles.

There are two key keys of hearing device that goes in your ear. There are the hard shell hearing assistive devices, which are, in most cases, 3D printed already. Then there are those devices that use silicone to provide a closer fit to the ear.

These are used in not only ear phones, but also sports devices for swimming and such. The traditional manufacture of these devices is a complex multi-step process that goes something like this.

An impression is made from the ear and ear canal using a modelling wax like substance, letting that harden then removing it. That impression then needs to be cleaned up and digitised (there are specialist scanners available).

Once you’ve got the form, you then need to manipulate that data, integrate the internal volume required for your electronics and export the data for 3D print (all the time accounting for shrinkage of both the impression material and the 3D print).

That 3D print is then used as the basis for a silicone model, into which more silicone is injected and set. Then the whole thing is cleaned up, finished, electronics added and shipped to the customer.

The new Formlabs?3shape workflow – direct model from scan, fill, break-out, finished article.

What Formlabs and 3shape have cooked up is a way to reduce the number of steps, most notably by removing the “Take impression, scan, 3D print form and make mould” portion.

Using one of 3shape’s new Phoenix scanners, a scan is taken of the ear. The digital file is then loaded into 3shape’s software, cleaned up, the internal volumes added for electronics and such, then converted into a simple mould that’s printed on the Formlabs machines.

That model is taken off the machine, the material injected and post-processed and you’re done.

Oh – and if you’re lucky/unfortunate enough to be in Vegas for CES, then you can pop and long and have a look at what Formlabs are up to (Including their Fuse 1 machine) in the North Hall of the Convention Centre, booth number 7908.