Go big or go home comes to mind when looking at Formlabs’ announcements today: The Boston-based SLA and SLS machine developer has announced the third generation of its Form stereolithography machines which have found a home on the desktops of designers and engineers across the planet.

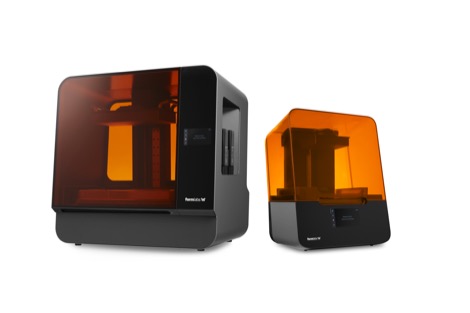

The new range features the Form 3, a desktop sized unit in the vein of previous machines, alongside the much larger Form 3L, which features a build size of 200 x 335 x 300 mm (7.9 x 13.2 x 11.8 in).

The Form 3 range is built on a process developed by Formlabs that differs from its previous iterations. Named Low Force Stereolithography (LFS), it uses a newly designed tank with a flexible base that aims to “drastically reduce the forces of the peel process, providing incredible surface finish and detail, and linear illumination to deliver accurate, repeatable parts.”

This new process is key to both the desktop Form 3, with its build envelope of 145 × 145 × 185 mm (5.7 × 5.7 × 7.3 in) as well as the larger, dual laser Form 3L unit. Formlabs’ machines to date, along with most SLA machines that build in an inverted manner (where the light source is projected through the resin tank onto the build platform) suffer from the same issue.

Each layer is built by the machine solidifying the resin between the resin tray and the build platform (which controls the layer thickness). Once done, to needs to separate from the base plate to draw in a fresh layer of resin using capillary action – referred to as the Peel process.

There are a number of methods of doing this. The Formlabs machines to date have tilted the rigid glass-based resin tray away while the build plate moves incrementally upwards. Autodesk’s short lived Ember machines slid the glass plate away from the solidified resin in a rotary motion.

The issue is that this process can cause suction between the solid part and the base plate – particularly when building large cross sections in a layer (this is why set-up software will typically angle your part to 45 degrees).

Anyone that’s run a Formlabs or similar machine and heard that gut wrenching clunking noise usually knows there’s trouble ahead.

As a minimum, the machine works harder to break the suction, so there’s a clunk as it pops away (meaning surface quality is affected – usually with ridges on the parts surface).

Worse case is that either the part sticks to the resin tray and breaks away from the build platform or the two are stuck together – either way, it’s a nightmare.

There’s a nice article on Formlabs’ support pages that explains this and how to circumvent/avoid it which is applicable to most similar machines.

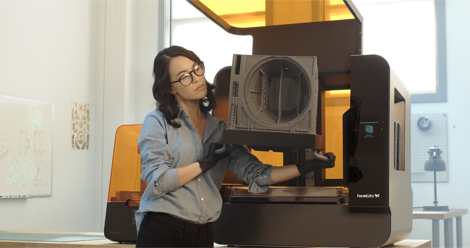

For the Form 3 machines, Formlabs is using a flexible resin tray base so that it can overcome the suction more consistently, but interestingly, it’s also moving the light processing mechanism and optics across the surface of that resin tray – which looks very different to how other systems are operating – it’s worth taking a look at the in-depth video.

What’s really interesting is how has allowed Formlabs to scale up the technology from the desktop sized unit (which has the same XY footprint, but an extra 10mm build allowance in Z) to a much larger unit. The Form 3L looks to be applying the same low cost of entry as Formlabs has done to date, but with some serious upgrades in terms of part size capability (or indeed, part count for small components) – in fact, five-times the build volume. It’s doing this by using a matching pair of the light mechanism and optics units.

Lastly, while the operation of the machines look similar to those before it, there’s also a nice new option in the materials side.

The new Draft Resin allows you to build in much larger layers (300 microns compared to 25 to 100 microns with other materials) , allowing you to build parts more quickly – with the assumption you’re happy with a drop in resolution.

If you want to talk costs, here are some options:

The basic Form 3 package is $3,499 which includes the Form 3 3D Printer, a finish kit (think, collection of Tupperware, some tools and bits and bobs), a single build platform, resin tank. Worth noting, no resin supplied with this option.

The Form 3 Complete Package adds another $1,500 and adds in Formlab’s own Form Wash and Cure devices for post processing (avoiding use of said Tupperware and tools), an extended service plan, extended warranty and a resin cartridge. The Form 3 is due to ship in June 2019.

The larger Form 3L is only available as a base package as yet, but it’s coming in at $9,999 and is expected to begin shipping in Q4 of this year.