MSC Nastran 2016 uses Shared Memory Parallel computing for faster performance

MSC has launched its 2016 versions of Nastran and Patran, promising improved performance and speed improvements, across both products.

While MSC Nastran 2016 has new multidisciplinary analysis solutions, Patran 2016 doesn’t look to have held back, with improved support for nonlinear and fatigue analysis.

The big news is Nastran’s speed improvements, which look to position it in the top echelons of multidisciplinary analysis tools available to engineers.

Nastran 2016 uses enhanced Automated Component Mode Synthesis (ACMS) method with Shared Memory Parallel (SMP) computing – in short, it helps deliver better performance and effectively use more cores for higher productivity.

There’s some big numbers being claimed by MSC for this, with 50 per cent parallel efficiency being observed for 16 processors. SMP Parallelisation can now be used to reduce the overall wall time stiffness matrix computations and stress recovery.

75 per cent parallel efficiency has been achieved with four threads with the job running three times faster than with a single processor.

The availability of Intel’s MKL Pardiso solver has also been extended to provide better scalability, likely lowering the overall elapsed time of simulations.

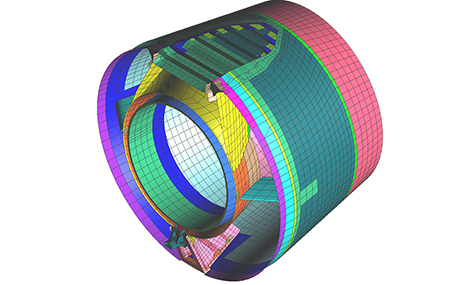

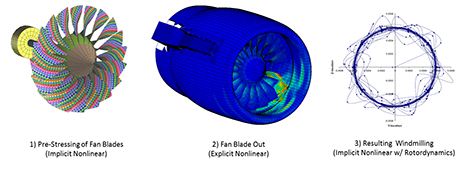

The new 3D modelling capability should allow users to model discrete blades and non-symmetric components of rotors and stators of rotating machinery, turbines and jet engines, while improving the accuracy of the rotor dynamic analyses.

This wasn’t possible with previous modelling solutions, while 3D models now allow engineers to see what is happening locally at each blade or at the component level.

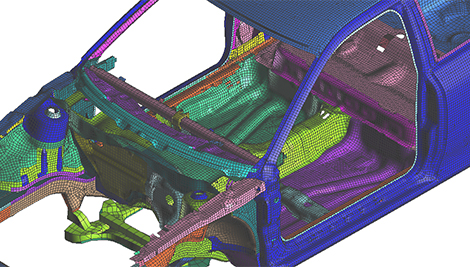

As with all modern simulation software releases, optimisation is a key factor here, with Global Optimization combining automatic multi-start global methods and gradient based local optimisation methods.

This approach promises to search the complete design space for the best possible solutions, and was designed to help produce safe optimisation for light-weighting in automotive and aerospace designs.

Multi-model optimisation should provide the ability to process separate design models with different topology or analyses to perform combined optimisation, an ability that’s enhanced to solve larger problems and without limit on the number of models.

MSC Nastran also comes with embedded fatigue solvers, nodal averaged stresses and strains are used for faster computation speed and a more realistic fatigue damage factors.

Skinning is implemented to create a 2D stress state on the surface of the model leading to fewer calculation points and enabling multi-axial assessments and correction on 3D solid elements.

Advanced nonlinear beam contact is implemented with segment-to-segment contact algorithm and support for general beam cross section, tube-in-tube contact, including beam offsets, reducing computational cost and providing better accuracy.

Elsewhere, interference fit analysis, now common to engineering applications, has been enhanced to handle large interferences and overlaps.

Three new models have been introduced to simulate complex material behaviour: a time dependent viscoelastic creep model; thermo-elasto-viscous plastic creep model, and the wonderfully named ‘Riedel-Hiermaier-Thoma’ model for concrete materials.

When it comes to results, Nastran 2016 has some new additions, including databases based upon the HDF5 standard, an open format that offers easier access via public viewers, Python, Java or C++.

https://youtube.com/watch?v=nDERf9NwUrA%3Frel%3D0