Ansys’ engineering simulation software has been drafted in by Ferrari Competizioni GT to help develop its next great GT car.

Every two or three years the engineering team pushes themselves to create an upgraded racing GT within a 12-month window, with production efficiency key to their success, with the team historically using Ansys Fluent meshing to deliver turbulence models and solver technology to take their cars’ performance to the next level.

Now the team is using Mosaic-enabled meshing to make what it claims as a considerable impact on its aerodynamics designs — letting them achieve improved accuracy with fewer cells and solving ‘in half the time’.

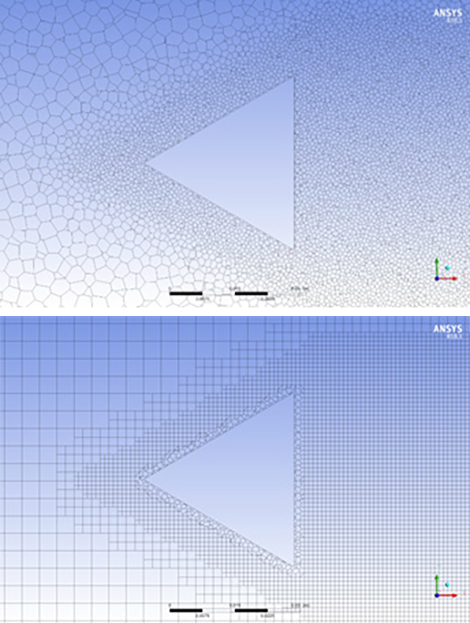

The Mosaic-enabled Poly-Hexcore meshes feature in ANSYS Fluent fill the bulk region of the simulation with octree hexes, maintain a high-quality, layered polyprism mesh in the boundary layer and conformally connect the two meshes with general polyhedral elements.

Ansys says that the Mosaic mesh-connecting technology has the potential to deliver exciting new combinations of meshing elements for solving increasingly complex parts with greater accuracy and speed.

The Ferrari Competizioni GT leveraged automated workflows to cut hands-on development time, use parallelisation to create high-quality mesh faster and solve in Ansys Fluent more efficiently.

Ferdinando Cannizzo, head of GT racing car development at Ferrari Competizioni GT, said: “With Mosaic technology and the Fluent end-to-end workflow, our team runs three times as many simulations in the same amount of time and develops cars faster than we ever could before.”

“Ferrari Competizioni GT cars represent the pinnacle of racing performance and we are proud to help them engineer new aerodynamic designs to obtain more victories on the track,” said Sandeep Sovani, director of global automotive industry at Ansys, and a man in for a shock when he finds out about F1.

“Teams are always looking for performance advantages and Mosaic meshing accelerates all stages of the simulation workflow, answers design questions sooner to help maximise production efficiency and supports tight developmental timelines.”