Kristan Bromley in action at the 2014 Sochi Winter Olympics, heading downhill on one of his own custom sleds

As far as winter sports go, at DEVELOP3D we’ve created our own Entirely Scientific Winter Sports Ratings System™ based on ‘sheer terror’.

At the bottom of the scale is curling, where hard-faced men and women bark orders at a lump of granite, while their underlings mop away at the ice sheet beneath in a frantic manner that makes housework seem almost pleasing.

Right at the other end, however, is skeleton bobsleigh, where competitors career head-first down an ice track, trying to go as fast as possible. It’s as mental as it sounds, and Britain is surprisingly good at it, a part of which comes down to the hardware used.

A Bromley designed skeleton bobsleigh sled

Britain’s number one men’s skeleton racer over the last 20 years has been Kristan Bromley, who when not competing, designs and manufactures the sleds needed for the 22 nations entering the next Winter Olympics.

With a world championship under his belt, two overall world series titles, numerous British national titles, and a three-times European champion he knows what is needed for the sled to perform.

Yet, to top off his track knowledge he gained a PhD from Nottingham University with a thesis entitled “Factors affecting the performance of skeleton bobsleds”, giving the British media the chance to nickname him Doctor Ice (Mr Freeze being both taken and unsuitable for a man of his doctorates) .

Kristan and his brother Richard established their company, Bromley Sports, in 2000, and now ship between 100 and 200 bespoke sleds to athletes around the world.

As well as this, the company is moving into more recreational winter sports, and has developed a patented sled for an exciting new snow activity, Baseboarding – face first sledging down ski slopes in a style similar to bodyboarding on waves.

The new Bromley Baseboard, a fun way to slide down the slopes, similar to bodyboarding

“Over the next two to three years we’re changing from purely providing a low volume, highly customisable Olympic-governed sled, to manufacturing up to 10,000 Baseboards for a mass market,” explains Bromley, who has a goal of becoming “the most advanced sliding sport product manufacturer in the world”.

The highly competitive world of skeleton bobsleigh is still the factor that lends its high precision manufacturing demands to everything Bromley produces.

“We’re giving athletes the tools to fight for Olympic medals,” explains a serious Bromley.

“Reducing aerodynamic drag by five per cent can cut an athlete’s time by one, two, or even three tenths of a second, and that’s enough to take them from tenth place right through to Gold.”

With more than 60 carbon fibre and stainless steel components in the skeleton sled, and the prospect of mass producing Baseboards, Bromley felt it was important to bring the whole operation in-house.

Rules for the skeleton sled are set by the Fédération Internationale de Bobsleigh et de Tobogganing (FIBT), the sport’s international governing body, but allow for the use of a variety of materials to come together to make a high performing product.

“Technology is one of the key parts of an athlete’s performance. In the same way that a Formula 1 driver can’t win the world championship without the best car, a skeleton racer would really struggle to win Olympic medals and world titles without the best sled technology.”

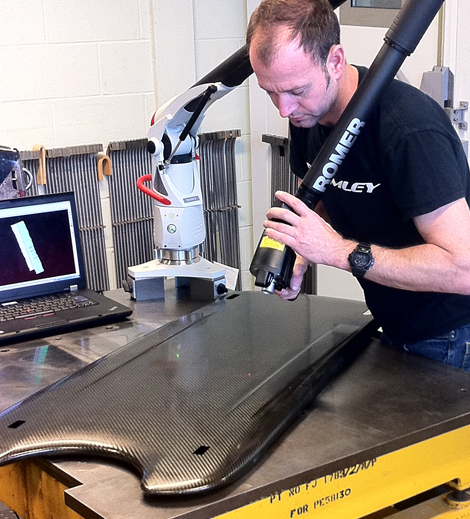

Bromley uses its Romer Absolute Arm for inspecting parts, scanning parts for reverse engineering, and even scanning the athletes themselves to help design the ergonomics of the sled

The development process includes ensuring that the sled is tailored to each individual athlete’s body, designed around the athlete’s personal ergonomics, reflecting the pressure points of their shoulders and knees.

The team use a Hexagon Metrology Romer Absolute Arm with integrated laser scanner to capture and reverse engineer the athlete’s form.

Once the athlete’s body shape has been captured Bromley can generate accurate mesh data for Computational Fluid Dynamics analysis in less than an hour, before the model is taken into PTC Creo.

Once the design is completed the file is dropped into Bromley’s CAM package to begin working on machining strategies, a key factor for a manufacturing process that includes vast amounts of tooling to produce the composite sleds is Bromley’s use of CAM.

Previously, most of the tooling work was sent to sub-contractors, but by bringing tool design and manufacturing in-house they realised they could create new designs, develop products faster, and innovate more efficiently.

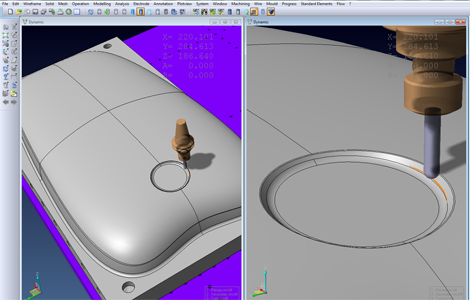

Bromley use Vero Visi for the machining of all its parts, whether to be used for composites tooling, or for direct manufacture

Bromley invested in Vero Visi and a Doosan DNM 650 VMC vertical milling machine and retro-fitted it with a Nikken fourth axis rotary table. Driven using Vero Visi’s multi-axis machining capability, it means that they can develop more complex tooling as well as machining prismatic style components.

“Although Visi is extremely powerful and flexible, it’s also simple to use. When we’re machining new tooling for the carbon fibre composites, being able to approach that particular tool with different machining strategies, and having the ability to manipulate those cuttings paths, is critical.

“To achieve the precision we need to help athletes win medals, we’ve found we can’t hit a tool with a ‘one toolpath suits all’ approach. We need to tailor those toolpaths and the cutting strategy in order to reduce machining time and produce a part with a high level of surface finish that requires minimal hand polishing.”

With Visi’s simulation capability, it helps ensure that the mould and toolpaths are ready for accurate and collision-free machining before they start to cut metal.

Once the composites have been removed from their moulds, they are finished and assembled onsite, mostly using jigs and fixtures that have been developed in house using the same design and tooling methods enabled by Visi for the sleds.

By using 3D design tools Bromley can build sleds with greater precision and to the required tolerances, and by keeping the process in-house, all this can be closely monitored and finished to perfection.

“Gaining performance is all in the detail,” concludes, Bromley, “and as an organisation trying to help athletes win Olympic medals we need the world’s best, to help the world’s best.”

Given that we think we can manage something a few notches down on our Entirely Scientific Winter Sports Ratings System™ scale, we’ll stick to Bromley’s Baseboards for now…

//www.youtube.com/embed/u6TDrXFCWeU