Dynamic Cutting heads up the list of new features in MasterCAM X8

CNC Software has announced MasterCAM X8 is to contain a new suite of programming tools focused on delivering speed, automation, and efficiency for all machining jobs.

New solids features, UI improvements, and workflow improvements are news, but it is Mastercam’s Dynamic Motion technology that gets the most attention.

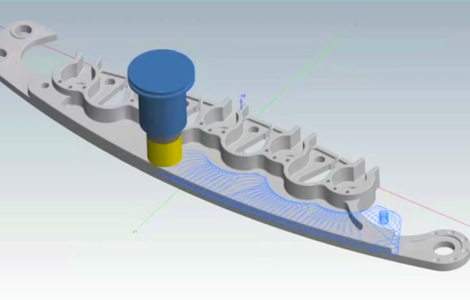

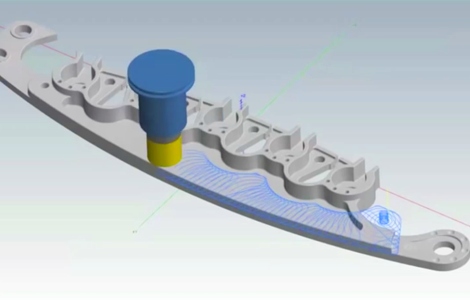

Its “new and exciting” approach to creating toolpaths, Dynamic Motion follows a ‘proprietary and sophisticated’ set of rules that take into consideration a broad data set to create the most efficient cutting motion possible.

//www.youtube.com/embed/ePIqFUb3pAM

MasterCAM states that Dynamic toolpaths calculate not only the area where metal will be removed; they also take into account the changing condition of the material throughout various stages of machining.

Its Solids interface and workflow has also been completely redone for the new release, aiming to make constructing and editing solids easier and more intuitive.

The existing Solids functions have been updated to reflect the new workflow. Along with a new interface, there are new features such as live preview, hands-on drag controls, and direct editing has been improved to make the process of model preparation easier.

CNC Software suggest that Mastercam X8 now delivers improved usability and the ability to customise workflows.

Panels can now be automatically hidden, docked to either side of the window, or undocked and placed outside of Mastercam. The graphics display has been upgraded to provide cleaner aesthetics, and clearer, more responsive selection while delivering a much improved overall look and feel.

As well as new usability and functionality updates, MasterCAM X8 has new mill-turning abilities

In addition, new icons provide a consistent color palette that is modern, clean, and – interestingly – colorblind friendly.

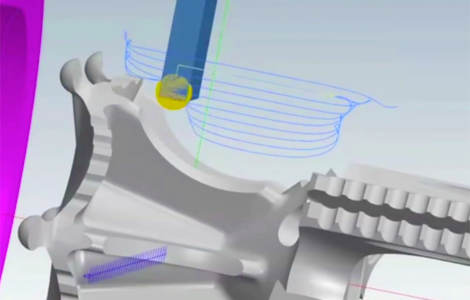

Elsewhere, 2D high speed toolpaths have been improved; Mill-turn includes the ability to define and select reference positions for the approach and retract moves in operations.

Multiaxis roughing is a new strategy that allows for the creation of multiaxis pocketing toolpaths to rough out pockets based on a floor or ceiling shape, while lathe toolpaths can now be included in stock model operations, which can be used for subsequent milling operations.