https://giphy.com/embed/26DN48PB9sHggRrag

Perhaps the most exciting announcement out of SolidWorks World doesn’t come from Dassault, but rather from Desktop Metal. The announcement centres around a new technology for additive manufactured part design called Live Parts.

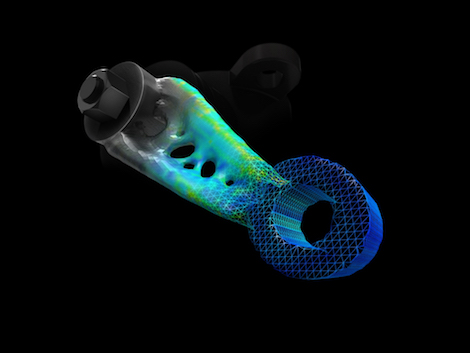

Built by Desktop Metal’s research and innovation group, DM Labs, Live Parts an experimental generative design tool that “applies morphogenetic principles and advanced simulation to shape strong, lightweight parts in minutes.” It uses the power of the GPU multi-physics engine to auto-generates designs in real-time.

This enables users to quickly realise the full potential of additive manufacturing – including material and cost efficiency, and design flexibility. The tool produces functional parts with complex, efficient geometries that are ideally suited for 3D printing. Desktop Metal is also claiming that “For users, Live Parts requires no prior knowledge of design for additive manufacturing techniques or guidelines.”

The system looks vaguely familiar to a topology optimisation engine, but assuming a relationship between the two would be a mistake – it all comes down to, what Desktop Metal, describe as Dynamic Transition Forces.

Other tools let you define multiple load cases. So you can say that a bracket has an upwards force, and in another case, a downward force. Without multiple load cases, if you added these forces together, you would get zero. So other tools can simulate the response of a part to multiple load cases.

However, multiple load cases do not address the real-world behaviour of parts. Parts have to transition from one load case to another over time. They don’t just live in a vacuum of isolated load cases. Instead, mechanical parts live in a constantly changing world. Living organisms operate in the same way. But what’s unique to living organisms is that they are able react to time-varying states.

Whether it’s high-frequency vibrations or low-frequency oscillations, cells react to forces by building up and emitting chemicals, over time, called morphogens – and these cause the organism to change behavior by growing stronger or atrophying – regardless as to the time scales of these transitions.

Live Parts is the only tool that simulates Nature’s dynamic transitional forces by combining a multi-physics engine with cellular growth and “chemical morphogenesis”. Your part is an organism living in a continuously changing world.

This means that if your part has an upward and downward force, you can model that scenario as not just two isolated load cases, but the following:

- An impulse that changes from up to down abruptly.

- A low frequency oscillation.

- A vibration that might generate fatigue

- A randomised collection of changes

In the real world forces are like waves in the ocean and every now and then they build up to create a perfect storm. Consider a hurricane hitting tree. Live Parts enables your parts to handle these forces because the parts are able to get stronger over time as they experience these dynamic transitional forces.

Live Parts is a totally new approach that models the growth process of parts in real time with continuously transitioning multi-physics.

If you’re interested, then a watch of this video might help.

“At Desktop Metal, we are committed to making metal 3D printing both accessible and successful for designers, engineers and manufacturing teams,” said Ric Fulop, CEO and Co-Founder at Desktop Metal. “In addition to hardware, we believe design for additive manufacturing software tools and techniques are critical to the successful fabrication of strong, lightweight parts that perform. We are excited to partner with Dassault Systèmes on the preview of our latest innovation, Live Parts, and to offer our software tool as a means for educational exploration to the largest community of engineers leading advancements in additive manufacturing.”

Beginning February 6, an early stage version of Live Parts is available to preview exclusively to all SolidWorks users. During the preview of the tool, input from the community will help guide its feature development.