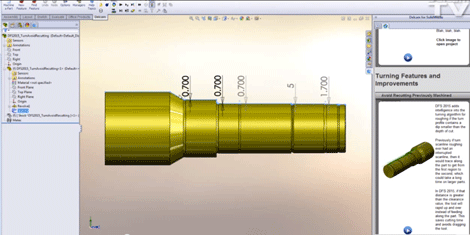

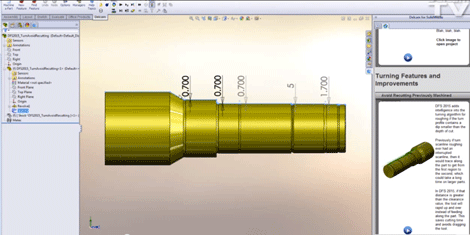

Delcam for SolidWorks 2015 adds intelligence into the turning algorithm to avoid tool dragging

It may be owned by Autodesk, but Delcam is still churning out the upgrades for its SoldWorks integrated CAM products, including some for programming three-axis tool paths and drilling.

Fully integrated into the SolidWorks environment to the point that it looks and behaves like an eery British doppleganger, the 2015 version offers full associativity so that any changes in the CAD model are reflected automatically in the tool paths, adding in the option to review the choice of cutting tools and machining strategies.

Programming of three-axis toolpaths for complex parts has been made easier and more reliable with the addition of automatic collision checking of the tool shank and holder, as well as the cutter, for both roughing and finishing operations. If a gouge is detected the toolpath can be recalculated with any segments that will cause a gouge clipped away.

//www.youtube.com/embed/7EVsJhkfCS8

Removing these segments of the toolpath leaves an area of unmachined stock that will need to be removed with a longer tool.

This extra toolpath is able to be calculated using a stock model of material remaining after the shorter tool has been used to ensure there is no re-machining of stock that has already been removed.

As part of this development, an additional function, called ‘maximum machine stock’, has been added that removes direct moves where clipping has occurred. These direct moves can leave witness marks on the part so their removal should improve surface finish.

Another improvement in three-axis machining allows stock models to be used in conjunction with other geometry, such as the part surface dimensions, solid models, the stock dimensions and boundary curves.

This addition gives better control over the area to be machined by each toolpath and so gives more efficient machining by allowing the user to confine toolpaths to specific regions and to eliminate air-cutting by referencing the stock model.

Three-axis flowline and isoline machining is now more flexible, with users able to choose to move the tool in an in-to-out direction or an out-to-in direction.

Drilling has been made easier in the new release with the introduction of a new hole type, ‘Thread Mill Hole’, which eliminates the need to create holes, pockets or sides, and thread features as separate items. It can be used either with holes created with the ‘Hole’ feature or those that have been identified with ‘Feature Recognition’.

The new ‘Find Feature’ command gives the ability to combine similar holes into groups on indexed parts. With previous releases, users had to have a separate feature for each hole but, now holes that are similar can be recognized and then grouped together. This makes them much easier to manage and edit.

A series of improvements have been introduced to make turning more efficient. The software is now able to produce toolpaths that rapid up and over previously machined diameters, rather than feeding along them. This reduces the overall cycle time and avoids dragging of the tool.