The symbiosis of topology optimisation and additive manufacturing will bring one of longest metal components ever manufactured by industrial 3D printing into space

During the annual trade fair Euromold, which takes place from 25th to 28th November 2014 in Frankfurt, a collaborative project to create a new antenna support component for the Sentinel 1 satellite will be presented by Altair.

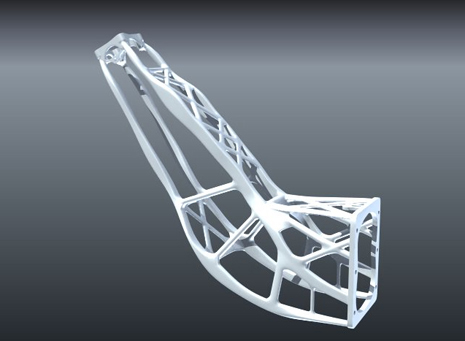

RUAG Space, a European supplier of aerospace products, wanted to redesign the aluminium component so that is was much lighter and significantly stiffer than its predecessor.

To redesign and optimise this part, engineers used Altair ProductDesign and then produced the component using 3D printing or additive manufacturing technology from EOS.

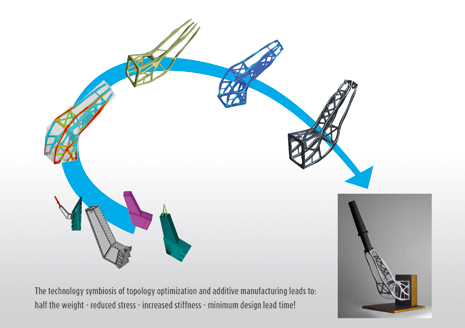

The Altair HyperWorks solver OptiStruct guaranteed a load-sufficient material distribution whilst for the design, solidThinking Evolve tool was used. This surface modelling tool allowed for fast implementation which meant that design freeze was reached just four weeks after the project started.

With the part ready to be 3D printed, the files were sent to a new generation EOS M 400 machine.

At around 40 cm in length, the aluminium antenna mount is claimed to be one of the longest metal components to be produced using the powder bed manufacturing method.

With the new support produced, it is currently undergoing rigorous tests to ensure that it’s ready to go into space. These tests are scheduled for completion by the end of the year.

A diagram showcasing the process used to create the component

According to Michael Pavloff, chief technical officer at RUAG Space, the production of this antenna support is by no means a one-off. “3D printing has enormous potential for our business, and we are currently in the process of developing further space applications.

“In the future it will be possible to create entire satellite structures using a 3D printer. This means that electrical harnesses, reflectors, heating pipes, and other assemblies that today still have to be manufactured individually could then be integrated directly into the structural elements,” Pavloff concludes.

This joint project to produce the antennae support component will be presented on the 26th of November at EuroMold 2014 as part of the CAE Forum at the Altair-hosted Additive Manufacturing Design and Engineering Symposium. Further information on the symposium and a registration form may be found here.