Latest release of CAMWorks adds in new cycles to support point to point operations

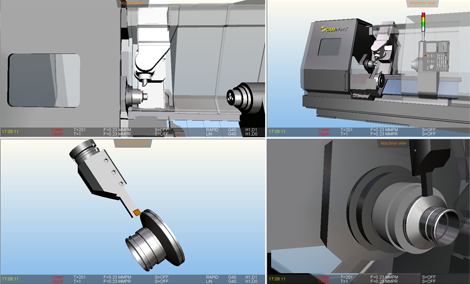

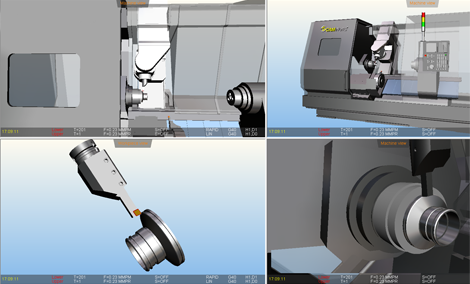

Geometric’s CAMWorks 2016 3D CNC machining software is set to offer new productivity-enhancing capabilities that it says will help companies with more cost-effective handling of design and manufacturing changes.

Operating inside SolidWorks 2016, the latest release is said to offer new customer-driven enhancements, including significantly reduced dependencies on sketches, and a new tool-based workflow that helps simplify toolpath generation for many typical jobs.

“The new surface selection method available to create prismatic, non-planar machining features provides a huge improvement for our CNC customers, because it eliminates the previous need to create sketches to define features. Now we only need to select existing model geometry to create features,” said Tim Fulton, CAM manager, Hawk Ridge Systems.

Other improvements in the 2016 release include:

– Interactive feature recognition enhancements, including the selection of non-planar edges and faces

– Improved chamfer machining options including the use of intelligent parameters and user feedback to provide users better control with chamfers

– Improved automatic feature recognition to simplify features and automatically recognize features by depth

– View and modify default machining strategies directly in CAMWorks without having to access the CAMWorks technology database (TechDB) in a separate application window

– Automatic pre-drilling of holes for high-speed machining applications in CAMWorks VoluMill

– New gun-drilling cycle specifically designed to support industry-standard tooling for deep-hole drilling and gun-drill operations

– New cycles to support point to point operations including center drilling, drilling, reaming, and tapping of holes in complex four and five axis components and assemblies

– For multitasking mill-turn machines, the ability to specify a fixed B axis angle for the tool and tool holder has been added for turning operations to provide better tool control

– Addition of a tool tree tab to simplify the creation of tools and tool cribs, more easily manage tools and operations including selecting, editing, replacing, and deleting tools

– Enhanced generation of setup sheets including the ability to incorporate multiple part and assembly images as well as tool images to reduce setup time

– Improvements to knowledge based machining (KBM) database to simplify automation using features, operations, and strategies