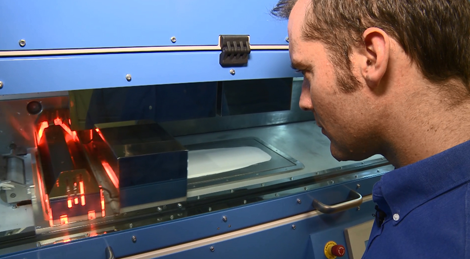

Professor Neil Hopkinson looking longingly at a 3D printer

A new 3D printer design based for High Speed Sintering (HSS) is being licensed to industrial machine manufacturers on a non-exclusive basis, with new machines being expected on the market from 2017/18.

The process selectively fuses polymer powder layer by layer, but instead of using lasers, HSS prints infra-red-absorbing ink onto a powder bed that is then exposed to infra-red light that heats the powder covered by the ink, causing it to fuse, while the rest of the powder remains cool.

The technology was originally developed by Professor Neil Hopkinson in his role as lead inventor at Loughborough University, with the new machines initially being built in the University of Sheffield’s Advanced Manufacturing Research Centre (AMRC) before installation in the University’s Centre for Advanced Additive Manufacturing (AdAM), of which Professor Hopkinson is now director.

The new HSS machine will be able to make parts up to 1m³ – of a much greater size than existing SLS machines.

The speed will depend on the size of the product, but the team estimate that small components will be built at a rate of less than one second per part, allowing AM to compete with injection moulding for high volume manufacturing.

The £1million project is funded by the Engineering and Physical Sciences Research Council.

Professor Hopkinson, said: “Additive manufacturing is already being used to make tens of thousands of a product – such as iPhone covers – and ten years ago that volume was unthinkable. This machine will enable serious production of volumes over one million, which is currently inconceivable.

“I believe history will repeat itself and in ten years’ time, producing volumes over a million using additive manufacturing will be commonplace.”