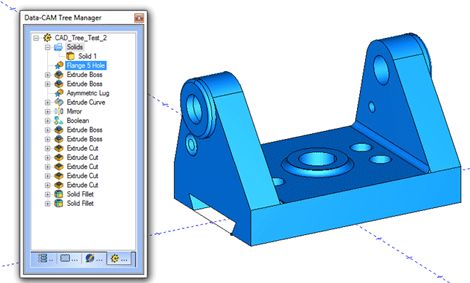

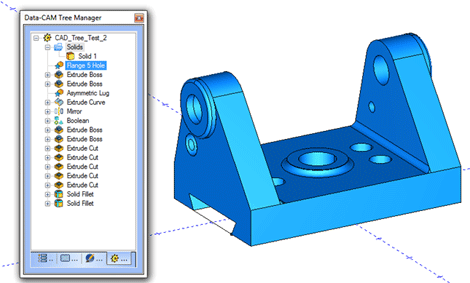

A new CAD Solid Action Tree in BobCAD-CAM allows users to modify any step of their solid creation

Lesser known on UK shores, BobCAD-CAM is, as the name suggests, a CAD/CAM CNC machining software for manufacturing businesses, and has now released its latest v27 edition.

Ranging from 2.5 axis to 3, 4 and full 5 axis simultaneous CNC machining the latest edition is aiming to streamline the process of selecting tools, materials and cutting strategies, producing the numeric code that the machine requires to actually machine the part fast.

In addition to CAM machining enhancements, the v27 software has received a major overhaul for its CAD functionality, adding a new CAD Solid Action Tree that allows users to modify any step of their solid creation.

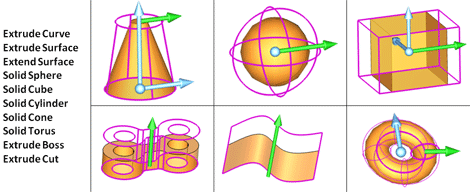

A new CAD shape library with 40 shapes to pick from gives users many common shapes to speed up the design process

The solid creation tree is fully associative to designed solid model, making editing steps to a drawn model faster and easier than before in BobCAD. Dynamic drawing has been added making simultaneous sketching and editing of values available to users.

“Users now truly have the freedom to really design with this system. Updating and changing your model is so easy, no longer will you dread that new revision sent from engineering!” added Myers.

A new CAD shape library with 40 shapes to pick from gives users many common shapes to speed up the design process, something the BobCAD software has never offered before.

Other CAD enhancements include new 2D Boolean features for faster editing of intersecting 2D geometry; and a Project to Z feature allows the user to extract edges from a 3D model and flatten the geometry along the Z plane or a defined axis.

v27 also provides new CAM machining benefits, including Mill 3 Axis Pro module enhancements to add finishing styles to the Advanced Planar option including “up” and “down” cutting which provides the ability to control the cut direction by forcing the tool to cut only in the up direction or down direction on the model.

Further control of the toolpath is provided by an Overlap Distance and a Minimum Height Change to handle shallow areas of the model.

Another important machining enhancement that was added is the new Adaptive Step-over for Planar surface machining which automatically adds more passes to eliminate steep jumps in the tool path.

A free trial download of the software is available here.